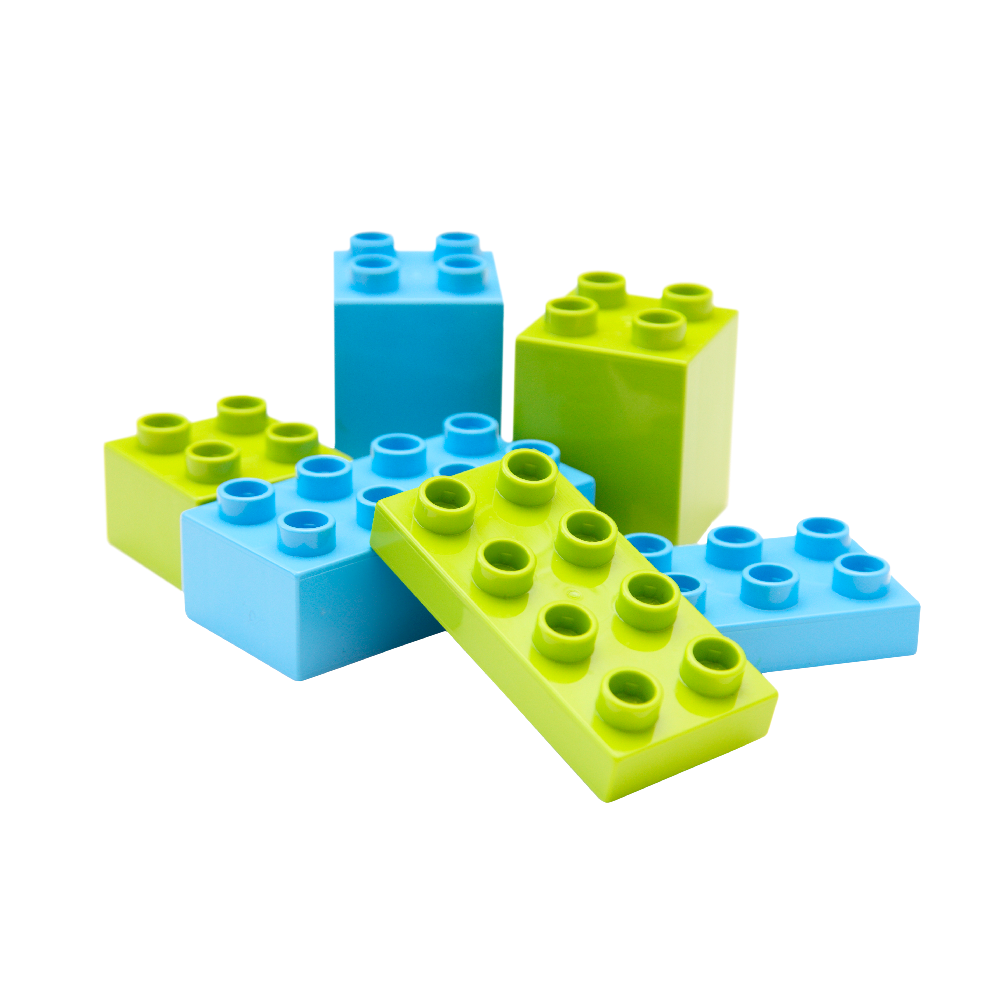

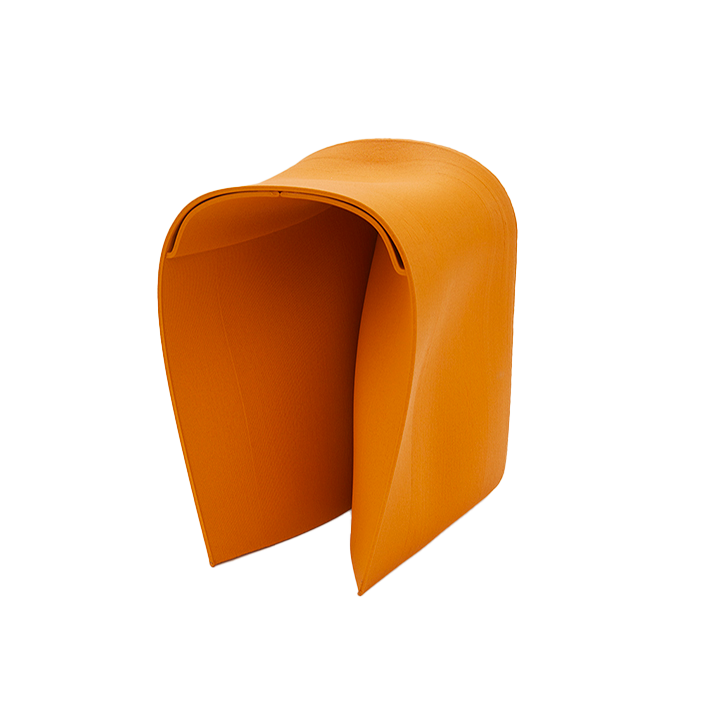

Stool

Orange peel, lemon peel and coffee grounds. What do these elements have in common? They are not necessarily a case for the organic waste bin, but can be reprocessed into practical everyday helpers and beautiful home accessories.

DATA & FACTS

Industry:

Furnishing

Renewable raw material:

Citrus peel

Companies involved:

Krill Design S.r.l.

Bioeconomy factor:

Utilisation of residual materials, low-resource manufacturing process

Status:

On the market

Utilising organic residues

Organic residues from agriculture and food production are considered valuable resources in the bioeconomy. Environmentally friendly processes can be used to create innovative products with a low resource footprint. Examples of this include handbags made from teak leaf leather or insulating packaging made from sawdust.

Organic composite made from citrus peel

An Italian company specialises in the processing of non-edible food waste. In a first step, the team produces a patented bio-composite from either citrus residues or coffee grounds and moulds it into long cords. Rolled onto a spindle, these can be clamped into a modern 3D printer and moulded into various objects. This creates stools, fruit bowls, candle holders or magazine racks.

Advantages of 3D printing

In addition to the utilisation of waste materials, the 3D printing process used is also particularly sustainable. It is energy-saving and there is no material waste or overproduction, as the exact amount of material required is only produced on demand.

Market maturity

The bio-based products are on the market and can be purchased via the company's online shop.

Weitere Produkte