Bio building bricks

Lego bricks are still made of plastic, which consumes a lot of oil. However, there has been a recent change in thinking. In addition to manufacturing products from bio plastics, by-products accrued from the wood industry are gaining in importance as a basic raw material for toy manufacturers.

DATA & FACTS

Sector:

Toys

Renewable resources:

Wood fibres and cereals

Participating company:

Ciddi Toys

Bioeconomy factor:

Wood fibres are accrued as a byproduct in the wood industry

Status:

ready for the market (summer 2016)

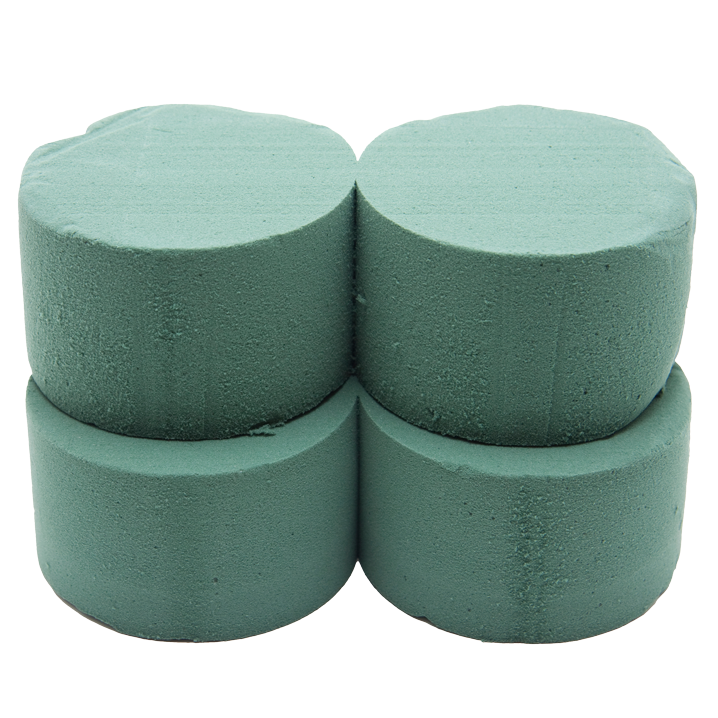

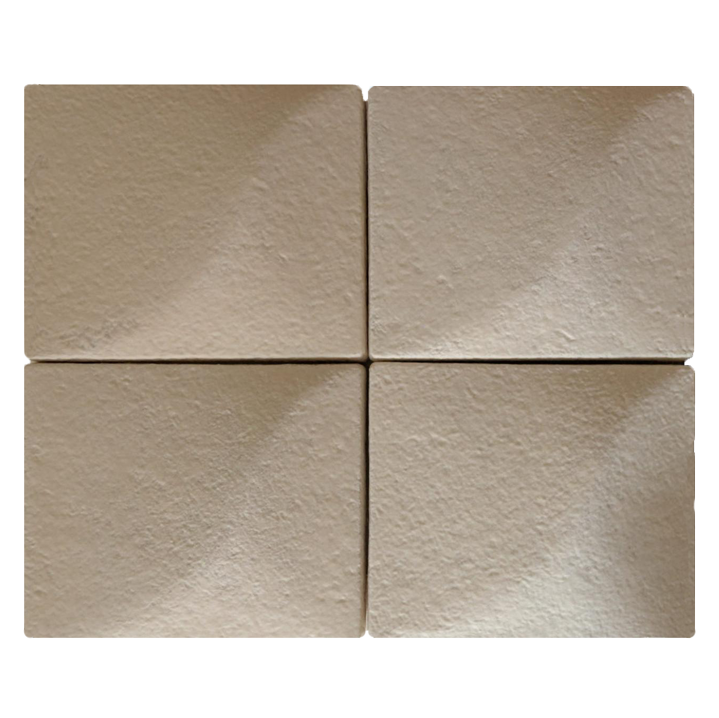

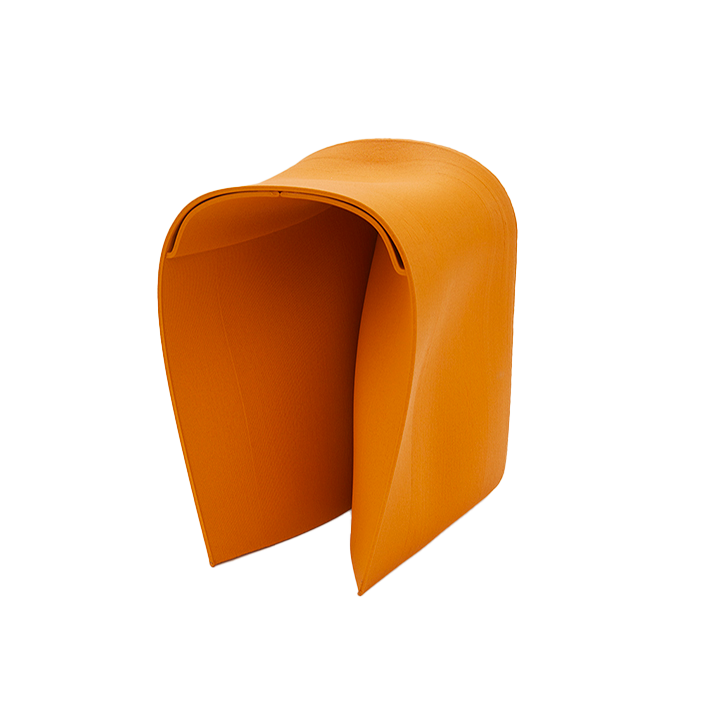

A by-product of the wood industry as a raw material

The eco-friendly blocks consist mainly of a mixture of wood fibres and a carbohydrate-rich raw material such as potato starch. Large quantities of the fibres are accrued as a by-product of the wood industry – up to 40% of the raw material. The majority is processed into paper. Thermoplastic composites are a new product from which the bricks are produced. The bricks have a wood-like appearance, high resistance and can be dyed. The blocks are dyed pastel shades using food colouring.

Sustainable building

Sustainable building begins with bio-based bricks in a child’s bedroom. There is virtually no need to use fossil fuels in the production of thermoplastic composites. Bio-based bricks are compatible with conventional models and are manufactured in Germany.

Ready for the market

At the moment Ciddi Toys’ building bricks are only offered in one basic colour and as Lego-sized pieces. The manufacturer has also planned other variants of the bricks. The building bricks will be produced from the following types of wood: bamboo, beech, alder, ash, spruce, pine, cherry and linden.

Weitere Produkte