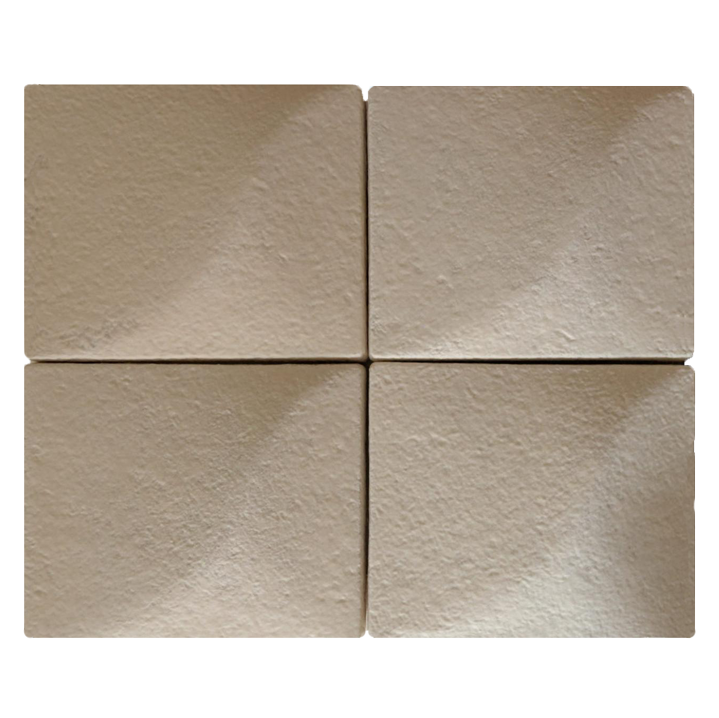

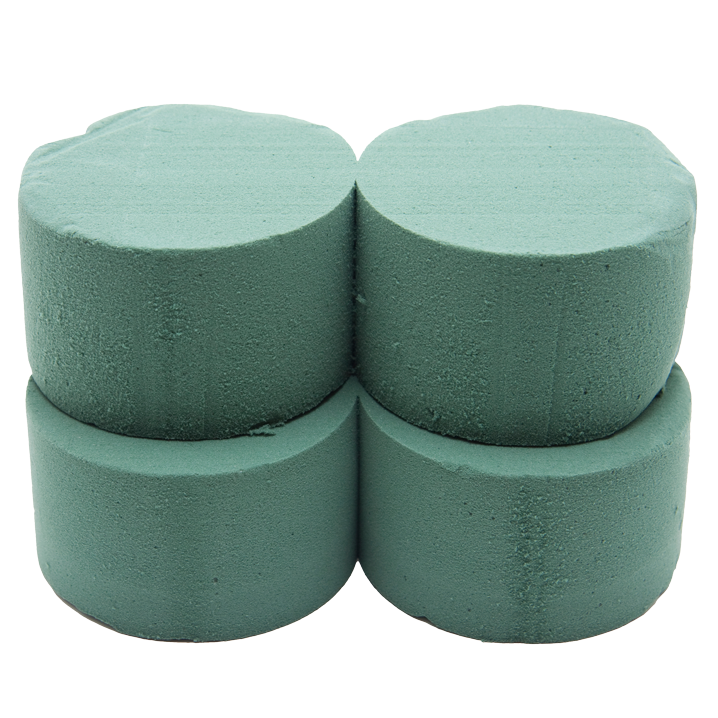

Floral foam

Without it, many floral arrangements wouldn't make much of an impression. Floral foam is commonly used in floristry to stabilise cut flowers, grasses, and branches in bouquets, and to provide them with water and nutrients.

DATA & FACTS

Industry sector:

Crafts

Renewable raw material:

Plant residues

Companies involved:

Flower Matter

Bioeconomy factor:

Utilisation of residual materials, environmentally friendly alternative to plug-in foam made from phenolic resins

Status:

Prototyp

Phenolic resins are the standard

Conventional plug-in foams have been fulfilling this task for many decades. They are also lightweight and easy to work with. One disadvantage is that they are usually made from phenolic resins, a synthesis of phenol and formaldehyde and therefore a synthetic plastic. The production of phenolic resins can produce environmentally harmful emissions that are not biodegradable.

Plant residues for fresh plants

A German-Thai company has developed a plastic-free alternative that consists of 100% wilted flowers. More specifically, the company uses the fibres of separated stems, mainly from carnations and irises, for the bio-based material.

The company has not shared details of the process. What is certain is that the residual materials are shredded and formed into a versatile, stable foam that offers the same benefits as conventional floral foams.

The foam can be used several times. When its stability and storage capacity deteriorate, it decomposes without leaving any residue in the organic waste bin or in home compost.

Market maturity

The start-up is currently still working with prototypes and is also developing a collection system that integrates plant waste from companies and private individuals.

Weitere Produkte