Bike

The bike is built from lightweight, thin-walled and resilient tubes with a minimum use of real wood. Unlike raw materials such as aluminium, iron or carbon, which are normally used for the construction of bicycles, wood is a renewable resource.

DATA & FACTS

Sector:

Chemical industry

Renewable resource:

Wood

Participating company:

Lignotube technologies

Bioeconomy factor:

The application of a renewable raw material

Status:

on the market

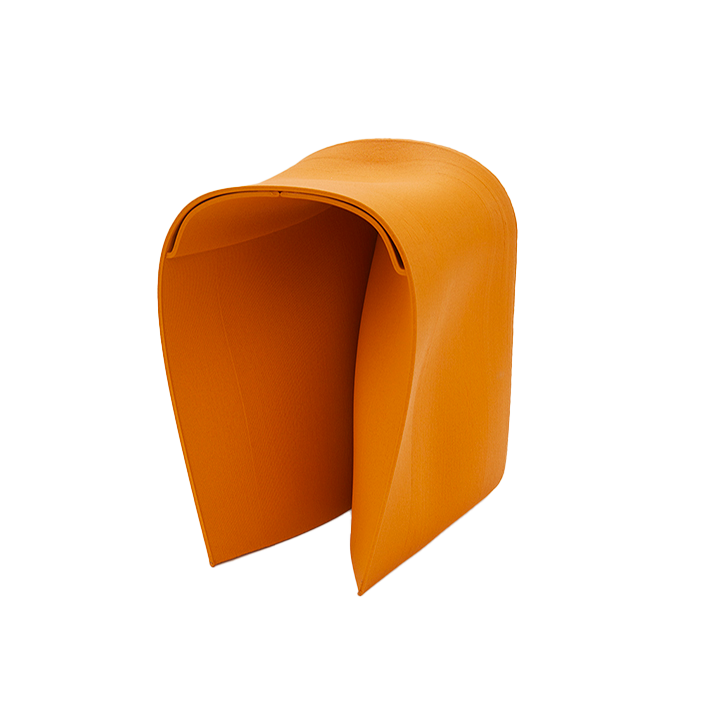

A designer bike made from Lignotubes

Inventors at the Dresden-based company Lignotubes technologies have developed a resource-efficient process for lightweight construction tubes – Lignotubes, which are manufactured as a multilayer composite of individual layers of veneer. The result is lightweight, thin-walled and resilient tubes with a minimum use of real wood. The individual veneer layers are glued crosswise. The first product is a designer bicycle with a frame made out of Lignotubes. The high-tech natural material is very versatile and can be used for furniture, simple constructions or for exhibition construction as well as for sport and recreational equipment.

Wood instead of aluminium, iron or carbon

Unlike materials such as aluminium, iron or carbon, wood is a renewable resource for which primarily only sunlight and CO2 is needed for its production. And now engineered wood has caught up in terms of strength and processability.

Ready for the market

The bicycles are manufactured and sold in Dresden. In the future, the company plans to bring out more models to the market to tap into a larger customer segment.

Weak points

Production not energy-saving

Weitere Produkte