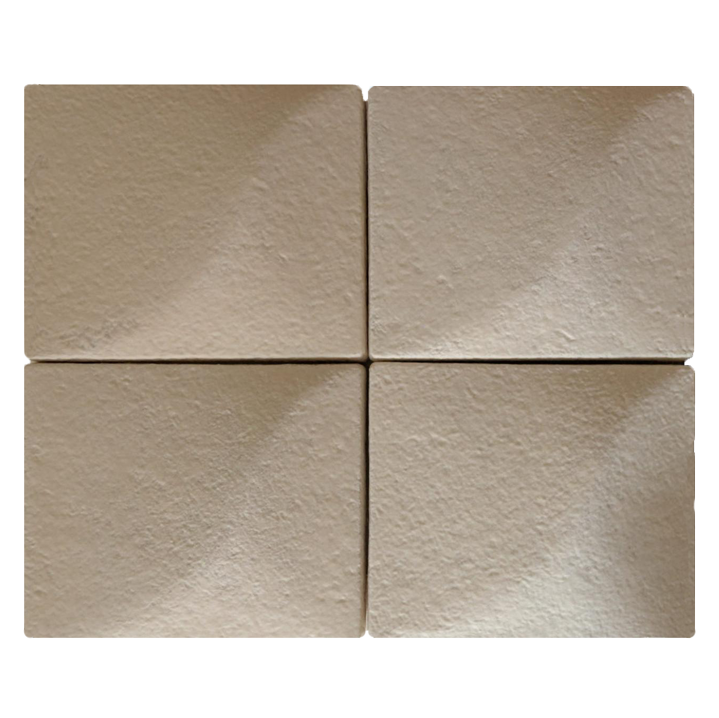

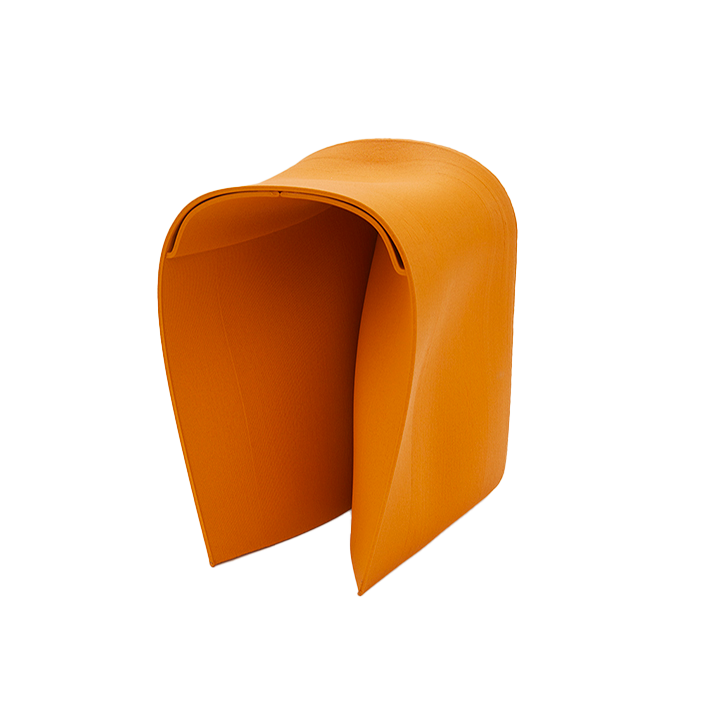

Dowel

The first plastic dowel revolutionized the possibilities of wall mounting in 1958. About 50 years after its invention, there is another innovation: the dowel turns green", and will now be made of a plastic, that consists of more than 50% of castor oil.

DATA & FACTS

Sector:

Construction

Renewable resource:

Castor bean

Participating companies:

Fischer | DuPont

Bioeconomy factor:

Proportion of bioplastics> 50%

corresponding to less consumption of petroleum-based plastic

Status:

ready for the market

Castor for firm hold

Normally, dowels are made from highly robust and resistant plastics such as nylon. The Baden-Württemberg-based construction company Fischer relies on a polymer that is partly based on castor oil as a raw material. The oil is extracted from the seeds of the castor oil plant Ricinus communis, which belongs to the spurge plant genus.

How the dowel gets biobased

The US chemical company Dupont extracts sebacic acid, a chemical synthetic building block, from castor oil. The synthetic polymer polyamide is produced together with other petroleum-derived building blocks. This new polymer is 58% biobased. Subsequently, Fischer processes the plastic granules into plugs.

Ready for the market

The bio-based dowels may be slightly more expensive; however, they are as robust as traditional nylon plugs. According to the manufacturer, the biobased dowels are well accepted by DIY market customers.

Weitere Produkte