Detergent

At the beginning of the 20th century, the "first automatic detergent" went on sale. It promised clean laundry after only 30 minutes at 95°C. Before that, the laundry had to be soaked, laboriously kneaded, rubbed, rinsed and wrung.

DATA & FACTS

Sector:

Consumer goods

Renewable resource:

Microorganisms

Participating companies:

Detergent manufacturers

Bioeconomy factor:

Biotechnologically produced enzymes increase washing power even at low temperatures

Status:

In the market

The washing day - a huge effort

For a long time, washing was the most energy- and time-consuming work in the household. Washing was done in a lye made of ash - ash, because the non-water-soluble substances mechanically helped scrubbing. In addition, the combination of water and ash produces a corrosive solution that causes the fibres to swell and decomposes the fats. After soaking and brewing in the caustic solution, the strenuous beating, kneading and rubbing, rinsing again, then bleaching and wringing took place: a huge effort that the washing machine and numerous ingredients relieve us of today.

Detergents today - a high-tech product

Today, detergents consist of about 30 different components. The environmentally harmful phosphates have been eliminated over the years and synthetic surfactants based on petroleum have been largely replaced by biodegradable surfactants.

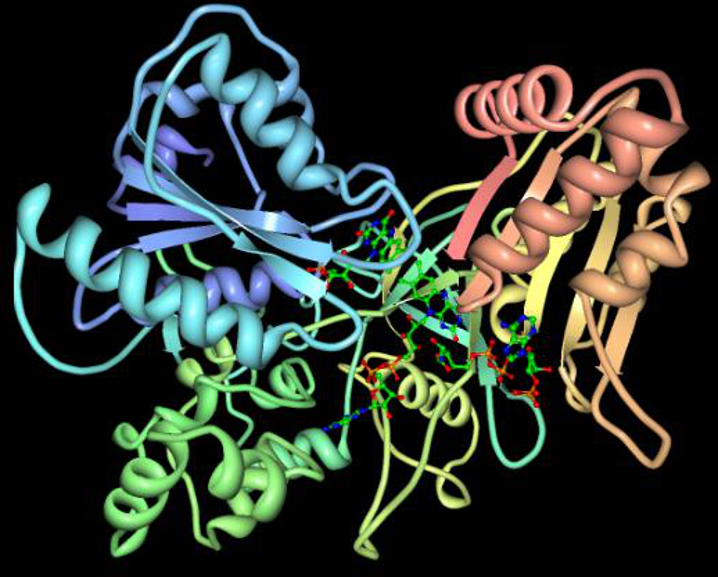

Enzymes were added. Each enzyme acts specifically for a certain organic substance, which it always degrades in the same way. Since enzymes work as biological catalysts, they are not consumed during the reaction. This enables them to be used effectively even in small quantities. With the help of genetically modified microorganisms, they can be produced in large quantities and high purity in a cheap and environmentally friendly way. The bioactive substances already develop their cleaning effect at low washing temperatures, which additionally saves energy and indirectly lowers CO2 emissions.

Another advantage is that the enzymes not only make the laundry cleaner, they also care for it: Biochemically, they nibble off the tiny nodules that make the cotton fabric rough.

Ready for the market

Enzymes are used in about 80% of detergents today.