Why are alternative protein sources needed?

The effects of industrial animal farming are diverse and well-known. It requires vast amounts of land and resources, raises ethical questions, and releases significant greenhouse gases like CO₂, methane, and nitrous oxide, along with nitrates into the environment. According to the Food and Agriculture Organization of the United Nations (FAO), livestock is responsible for 14.5% of global greenhouse gas emissions – most of which comes from the cultivation, processing, and transport of animal feed. Within livestock farming, enteric fermentation – the formation of methane in the digestive tract of ruminants – is the second-largest source of greenhouse gas emissions. While methane has a significantly shorter atmospheric lifetime than CO₂, it is about 25 times more harmful to the climate.

At the same time, global meat consumption is expected to continue rising in the foreseeable future, particularly in developing countries where the middle class is growing and disposable income is increasing.

Considering the growing protein demand of the global population, traditional animal production systems are reaching their economic, ecological, and ethical limits. In many industrialized countries, meat consumption and the associated intensive livestock farming are part of a controversial debate. While some people continue to consume meat regularly, demand for vegan and vegetarian foods is increasing – often motivated by concerns for animal welfare and climate protection.

Advantages of alternative protein sources

Alternative proteins – such as those derived from protein-rich plants, algae, insects, or produced through fermentation – require significantly fewer resources compared to meat (for example, pea protein products use up to 80% less water than beef products) and less farmland. Their production also emits fewer greenhouse gases. In 2023, Germany’s livestock sector accounted for around 35 million tons of CO2-equivalent (CO2e) direct greenhouse gas emissions. This corresponds to roughly 68% of the direct emissions from the entire agricultural sector and 5.3% of nationwide greenhouse gas emissions. A closer look at emissions per unit of protein produced also highlights differences between animal and alternative foods – especially when it comes to beef. Beef produces 50 CO₂e per 100 g of protein — far more than tofu and soy milk (2.1 CO₂e) or insects (0.4 CO₂e) per 100 g of protein.

Another advantage of many alternative protein sources is that they can be produced locally – a key factor for food security, as global supply chains can be disrupted by conflicts, shortages, or pandemics, and harvests are increasingly affected by climate-related extremes. In addition, many of these protein sources offer positive health effects, as they typically provide less saturated fat and cholesterol while increasing fiber intake (see Chapter 3 for details).

Thus, alternative protein sources can make an important contribution to a sustainable, healthy, and climate-resilient diet. Innovative production methods also promise new business opportunities and a transformation of the food industry (see Chapter 2).

Definition of alternative proteins

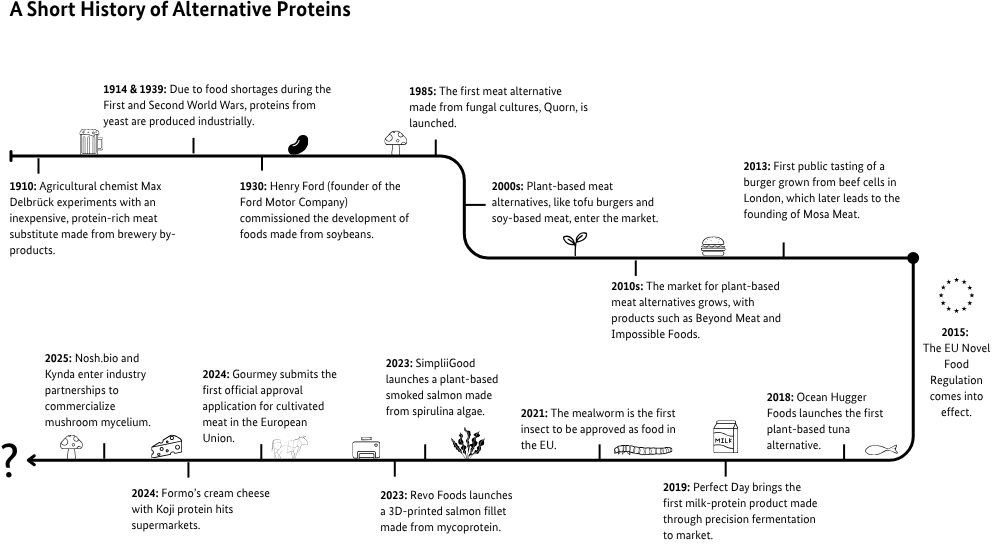

Alternative proteins generally refer to foods or ingredients that serve as substitutes for products from animal farming, such as meat and dairy, while offering a comparable protein content. They include protein-rich plants (legumes, nuts, grains), algae, insects, proteins produced through fermentation, and cultured animal products.

Page 2 of 6

Germany: Heading Toward a Protein Transition?

Germany is the largest market in Europe for plant-based alternatives to animal foods – and it continues to grow. Between 2022 and 2023, revenue increased by 8% to €2.2 billion. Production volume also rose: in 2023, nearly 122,000 tons of meat alternatives were produced, up 16.6% from the previous year.

At the same time, consumption of plant-based alternatives continues to rise. According to a representative 2023 survey by the Good Food Institute (GFI), 41% of Germans consumed plant-based meat alternatives at least once a month. In addition, 22% reported using such products more frequently than five years ago. The share of people who consume vegetarian or vegan alternatives daily has doubled between 2020 and 2024 – from 5% to 10%.

This trend shows that rising demand and acceptance of alternative plant-based protein sources among consumers is evident, which is also reflected in declining meat consumption. Per capita meat consumption in Germany has been steadily decreasing. In 2014, the average consumption was around 60 kilograms per person per year; by 2023, it had fallen to just under 52 kilograms, a reduction of about 15%. In 2024, per capita meat consumption in Germany slightly increased to over 53 kilograms. However, a GFI survey indicates that 35% of Germans plan to eat less pork in the coming years, 30% less beef, and 22% less poultry.

Similar trends are seen for butter, cheese, and milk: per capita consumption of butter, milk fat, and spreadable dairy products fell to 5.6 kilograms in 2023, down 1.4% from the previous year. Cheese declined by 3.2% to just under 24 kilograms per person, and liquid milk fell by 1% to 46 kilograms. Only egg consumption has increased in recent years, reaching 249 eggs per person in 2024 – 10 more than the previous year.

Raw material base

Germany has a solid foundation for producing alternative proteins, with the cultivation of domestic crops such as legumes, grains, oilseeds, and seeds, as well as imports of non-native protein crops like soy. Combined with the use of residues from agriculture and food processing, this creates a diverse potential for protein supply. Legumes such as peas, beans, soy, and lentils provide positive ecological effects during cultivation: with help from rhizobia, they can absorb nitrogen from the air, partially fertilize themselves, and improve soil quality – a natural process that conserves resources, reduces the need for mineral fertilizers, and benefits the environment.

However, actual self-sufficiency in protein crops like legumes remains low. Germany and the EU rely heavily on imports. Strengthening domestic cultivation requires, among other measures, breeding programs to develop location-adapted varieties, such as cold-tolerant soybeans with pest resistance and high-yield domestic legumes.

In the future, the cultivation of additional protein-rich crops may be possible – such as chickpeas, sweet potatoes, millet, or chestnuts. At the same time, new, largely untapped protein sources such as mycoproteins from fungi, algae, or insects offer promising avenues for resource-efficient and more independent protein supply.

Page 3 of 6

Overview of alternative proteins

Alternative proteins vary in production method, composition, and taste. They also have different characteristics, advantages, and challenges. The following six categories of alternative protein sources are gaining importance and have significant potential to partially replace conventional animal-based foods.

1 | Plant-based proteins

Legumes such as soy, lupine, or peas can serve as a direct plant-based protein source for human nutrition rather than as animal feed. They provide high-quality protein for a balanced diet.

- Special characteristics: Plant proteins can be consumed unprocessed as whole legumes or used as isolates or extrudates in plant-based meat alternatives. Modern meat substitutes increasingly use fermentation to enhance flavor and texture to mimic meat.

- Production: Optimization focuses on breeding higher-yield domestic varieties and climate-adapted non-native species like soy.

- Advantages: Legumes improve soil quality through nitrogen fixation; production scalability through farming is well-established.

- Challenges: Plant proteins often have lower biological value than animal proteins, requiring larger amounts or specific combinations to achieve comparable nutrition. Climate change also increases the prevalence of plant diseases, posing a threat to future cultivation.

2 | Algae

Algae are generally divided into single-celled microalgae and macroalgae. They can be processed into powders, tablets, supplements, or directly into foods such as smoothies, snacks, pasta, or meat substitutes. Cultivation can occur in open ponds or bioreactors, with or without light, depending on species and target product.

- Special characteristics: Very high protein content (up to 70% in species like spirulina or chlorella); naturally contains omega-3 fatty acids and essential vitamins.

- Production: Microalgae grow in photobioreactors using sunlight and sometimes nutrient-rich wastewater; closed vertical systems allow urban production with high productivity. Macroalgae can be grown in coastal areas or open sea.

- Advantages: Algae absorb CO2 during growth, and many species remain largely unexplored as food sources.

- Challenges: Few algae species are approved as foods (Novel Food regulation). High energy consumption for photobioreactor production (aeration, lighting, circulation, temperature control) makes microalgae less cost-effective than open systems, which are seasonal and less controllable.

3 | Fungal mycelium (mycoprotein)

Fungi provide high-quality protein for human nutrition. Their root-like mycelium can be mass-cultivated in bioreactors as an alternative protein source. Single-celled fungi, such as yeasts, can also be produced this way. Mycoprotein has become the collective term for alternative fungal proteins.

- Special characteristics: Texture, consistency, and umami taste are often very similar to meat.

- Production: Well-suited for using agricultural and industrial by-products, such as starch and sugar residues, oat husks, or juice production waste.

- Advantages: Contains nutrients often missing in plants, such as high-quality protein and vitamin B12. It also offers more fiber and unsaturated fats than meat and is generally not considered Novel Food when approved species are used.

- Challenges: Less versatile than precision fermentation products due to natural flavor and variable composition. Chitin in fungi can be difficult for some people to digest.

4 | Edible insects

Edible insects can be consumed dried, ground, or whole, as snacks, protein powders, or ingredients in bars, pasta, and baked goods. They are raised on specialized insect farms.

- Special characteristics: Amino acid profile similar to meat or fish; protein content around 70%.

- Production: Excellent at converting waste streams, suitable for bioeconomic circular systems.

- Advantages: Around 1,900 edible insect species; no slaughter waste except chitin, which has high-value uses (e.g., animal feed). Insect meal can replace fish meal in aquaculture.

- Challenges: Strict approval processes (Novel Food regulation); low consumer acceptance in Western countries; some insect components can trigger allergies.

Novel Food

Novel Food refers to foods not significantly consumed in the EU before May 15, 1997, and falling into at least one category defined in Article 3 of the Novel Food Regulation (EU) 2015/2283. These foods require health assessment and approval before entering the market.

5 | Proteins from precision fermentation

Targeted microorganisms produce specific animal-free proteins in controlled fermentation processes – such as proteins found in milk, eggs, or meat.

- Special characteristics: Produces animal-identical ingredients without using animals.

- Production: Costs are still high due to technical challenges and limited bioreactor capacity, though initial successes exist.

- Advantages: Many foods can use these proteins; ingredients in familiar foods (e.g., milk protein in cheese or egg protein in baked goods) can be replaced 1:1 without changing consumption habits. Surveys show roughly half the population is open to foods from precision fermentation.

- Challenges: Typically subject to Novel Food regulations; production must scale to meet demand.

6 | Cultured meat

Cultured meat is made by taking a few animal stem cells and growing them in a nutrient medium under controlled, sterile conditions. The cells then develop into meat-like texture or muscle tissue, sometimes on or within plant-based scaffolds.

- Special characteristics: Quality, fat content, and texture are controllable, likely producing taste close to the “original.”

- Production: Currently complex and expensive; scaling and optimization are needed for large-scale, cost-competitive availability. Alternatives to fetal calf serum in the nutrient medium are in development.

- Advantages: Produces animal products without slaughter, avoiding ethical concerns; closed systems use significantly less water than conventional livestock farming.

- Challenges: Technology is still developing; research and scaling are required to reach commercial volumes. Sustainability benefits depend heavily on production methods.

New circular systems

In the Fraunhofer flagship project "FutureProteins", six Fraunhofer institutes demonstrate how various alternative protein sources can be combined and used in a circular approach. By linking plants (such as potatoes, alfalfa, wheatgrass, and peas), insects (e.g., mealworms), fungal mycelium, and microalgae, the project creates as closed-loop systems as possible, producing in a climate-independent and resource-efficient manner while efficiently using by-products. For example, plant residues serve as substrates for cultivating insects, fungi, and algae, while waste heat is used for climate control.

Page 4 of 6

Researching the future: projects and examples

The Federal Ministry of Research, Technology and Space (BMFTR) has long been supporting research into alternative proteins. The following highlights a selection of projects that have been supported and continue to be supported as part of this commitment.

Kernels as powerhouses

The GreenXutaProtein project is part of the KMU-innovativ funding program. Its goal is to develop a “green” extraction platform technology for proteins from Xuta kernels by 2026. The project was launched in 2024 by Leibniz University Hannover in cooperation with Elea Technology GmbH.

In 2022, the Xuta kernels from the Central American plant Jatropha curcas L. were approved by the EU as Novel Food. They contain about 25% protein, rising to 55% after oil removal. The kernels also provide all essential amino acids. According to project leader Tuba Esatbeyoglu, the plant “is very convincing from a nutritional profile perspective and offers high potential,” also because it can grow on degraded soils and requires little water.

The project aims to develop a platform technology that allows proteins to be extracted from the kernels. Gentle, non-heat-based methods such as Cold Plasma (CP) and Pulsed Electric Field (PEF) are being tested. Because both methods are energy-efficient and do not require carbon-based chemical solvents, the extraction platform is considered “green.” The extracted Xuta kernel proteins are intended for use in milk and meat alternatives.

Cheese without cows

In the KassettE project (Casein-Fat Tandem Expression for Food Production), the start-up Formo Bio GmbH is developing a precision fermentation process for cheese alternatives. The KMU-innovativ funding runs from 2024 to 2026.

Casein and fat, the main components of cheese, are to be produced simultaneously in a single organism (such as the yeast Yarrowia). Normally, casein is broken down by certain enzymes because it is recognized as a foreign protein. The goal is to protect casein from this breakdown, allowing economically viable production.

This approach saves resources and simplifies further production of cheese alternatives. Suitable microbial strains are selected, the fermentation process is optimized, and analytical methods for the casein-fat mixture are established. Initial lab prototypes of cheese alternatives have been produced and evaluated.

In-vitro meat from umbilical cord blood

The BMFTR funded the CELLZERO Meat project through the “New Products for the Bioeconomy” idea competition. The project, completed successfully in 2024, advanced the in-vitro production of cultured meat.

The team from Anhalt University of Applied Sciences and the Research Institute for Farm Animal Biology developed a method to collect stem cells painlessly from piglet umbilical cord blood, which are then cultured in an algae-based medium. Cold plasma was also used instead of antibiotics to maintain sterility.

The process completely avoids slaughter, animal serum, and antibiotics. The stem cells differentiate into muscle, fat, and connective tissue cells within the nutrient-rich algae medium. Using 3D printing, the cultured cells are processed into meat-like tissue structures – from burger patties to schnitzel-like products – while retaining typical sensory properties. Studies confirm that texture and color closely match conventional meat. All components along the production chain were analyzed, optimized, and documented to make them available for other actors in alternative meat production. Follow-up projects for industrial scaling are in preparation and could open new development perspectives for agriculture.

Selecting the right proteins with a database

The Sustainable Protein Ingredients project (part of BMFTR’s NewFoodSystems innovation space) ran from 2020 to 2024, developing a comprehensive protein database as a foundation for selecting proteins or protein combinations for specific applications. In a second step, alternative proteins were to be used in food and feed products.

Led by Prof. Ute Weisz at Rheinische Friedrich-Wilhelms-Universität Bonn, researchers collaborated closely with various industry partners.

Questions to Ute Weisz

Were the overarching project goals achieved?

Yes. We developed a comprehensive protein database based on commercially available proteins, now serving as a tool for targeted product development. Our project partners also investigated the use of plant proteins in various food applications, generating knowledge that can inform future product innovations.

Who is the protein database intended for?

The database is designed for the entire food and ingredient industry. It allows companies to select suitable proteins for specific applications and compare their own products with market products to understand how functional properties can be improved through targeted modifications. The database remains available after the project’s conclusion.

Have product innovations been brought to market since the project ended?

The project operated in a pre-competitive space, providing the foundation for innovations. It is now up to companies to further develop and implement them. Two partners have already succeeded: a new, less-processed lupin-based plant milk was developed, and sunflower protein ingredients were optimized and processed into sunflower extrudates.

Egg without hens

The BioEggFlavor project is another KMU-innovativ initiative. Since 2023 and continuing to 2026, a team from the University of Hohenheim and New Path Bio GmbH is developing vegan egg products.

Vegan egg products have so far had noticeable deficits in sensory qualities such as color, texture, and taste compared to conventional egg-based products. The goal is to develop a plant-based egg that produces a characteristic egg flavor (combining taste, smell, texture, and mouthfeel) through thermal reactions during preparation, without added flavorings.

The process begins with partial enzymatic hydrolysis – breaking down plant proteins into smaller components using enzymes. This generates a mixture of amino acids, peptides, and protein fragments that act as flavor carriers and precursors. By combining these with other plant ingredients and applying household-like thermal treatment, an egg-like flavor profile is created. Analytical methods are used to monitor both desired flavors and potential off-flavors, while other quality attributes, such as color and nutritional value, are continuously considered to ensure high product acceptance.

Urban agricultural systems

The food4future (f4f) project is a collaborative effort under BMFTR’s "Agricultural Systems of the Future" funding program. Since 2019, it has explored innovations and new production methods for resource-efficient and healthy food supply. The project is currently in its second funding phase. Coordinator Monika Schreiner provides an overview of current progress and short- and long-term objectives:

Questions to Monika Schreiner

Why is food4future relevant?

“Already today, more than 50% of the world’s population lives in cities; by 2050, over 70% will. food4future develops new ways to produce food where it is needed: directly in cities – locally, resource-efficiently, and sustainably. The project focuses on alternative food sources such as macroalgae, halophytes, jellyfish, and insects, using innovative technologies in modular indoor-farming systems.”

What is unique about the project?

“It’s not just about new foods, but also their environmentally friendly cultivation, processing, and integration into urban spaces. Biological, technical, social sciences, and design disciplines work together with actors from science, industry, urban planning, and society. Another novelty is combining research and practice: indoor cultivation systems will be integrated into real urban environments and tested in living labs.”

How do you define a healthy diet?

“It’s not just about vitamins, minerals, or unsaturated fats – it’s also about producing food in a resource- and environmentally-friendly way. Our work follows the One-Health principle, considering human, animal, and environmental health together.”

Are any food4future products on the market yet?

“Currently, food4future products are not yet on supermarket shelves. Some concepts and prototypes are in planning, such as the pilot facility for halophytes in urban basements, or are already being tested, for example with spas like Therme Bad Saarow. These pilot facilities are the first prototypes, now being further developed with industry partners toward market readiness.”

What are your next steps and goals?

“The focus is on implementing innovative urban indoor cultivation systems for algae, insects, or salt-tolerant plants. The goal is to make these systems technically and automatically scalable, and to develop new foods. Social acceptance is central, for example through the Future Food Living Lab, where people can experience and co-create new foods. In the Berlin area, we are also testing how these approaches can integrate into urban environments.”

Page 5 of 6

A glimpse into the future: what might our diet look like?

It is 2050 – Germany has achieved climate neutrality. A key factor was the shift to a climate-friendly diet. Prosperity today is reflected in health, quality of life, and conscious resource use – which benefits everyone. Industrial livestock farming is no longer necessary, and alternative proteins are now a natural part of the diet. A wide variety is available anytime and affordably: from insects and algae to cultured meat and fermented fungal proteins. Biological grazing covers remaining animal product needs. Food production is more resilient, mostly local, and transparent.

This could be a positive future scenario for our nutrition, in which alternative proteins play an important role. Monika Schreiner from the food4future project envisions something along similar lines: “In an ideal future, cities are not just places of consumption, but also of food cultivation. Fresh, nutrient-rich foods grow on rooftops, facades, and in vacant industrial and office buildings. Diets are more diverse. Algae, insects, and even jellyfish are everyday foods – not exotic exceptions, but tasty and healthy alternatives. Not all alternative sources are eaten in their original form: ingredients are extracted and used as substitutes in conventional foods, for example algae or insect proteins in bread and pasta,” she says.

Pascal Bieri, co-founder of Planted, says the perfect diet of the future is “sustainable, cruelty-free, healthy, and enjoyable – all without sacrifice.” Tim Fronzek of Nosh.bio adds: “We believe animal-free and hybrid products can play a transformative role. Our vision is clear: a world where food harms neither the planet, animals, nor people.”

The future will tell – but the foundations are being laid today by dedicated people in research, industry, and politics.

Reality check: the protein transition

To make these scenarios real, transformative changes – the so-called protein transition – are necessary. Numerous technological, social, and institutional innovations are currently being developed. The "Responsible Innovation for the Protein Transition" (RI-ProT) project at TU Berlin analyzes which aspects of protein production are important and how alternative proteins can contribute to future food systems. Using transparent criteria, the project assesses which alternatives are truly responsible, health-promoting, equitable, and environmentally sustainable.

Page 6 of 6

More Information

More at bioökonomie.de

Multimedia-Story (in German): Lebensmittel der Zukunft

News: GFI-Reports: Record investment in alternative proteins

Success Story: Food production of the future

Further Information (in German)

Alternative Proteine in Deutschland, GFI Europe, Mai 2023. PDF-Download Full Report

Beitrag der Landwirtschaft zu den Treibhausgas-Emissionen, Umwelt Bundesamt. Stand Juni 2025. umweltbundesamt.de