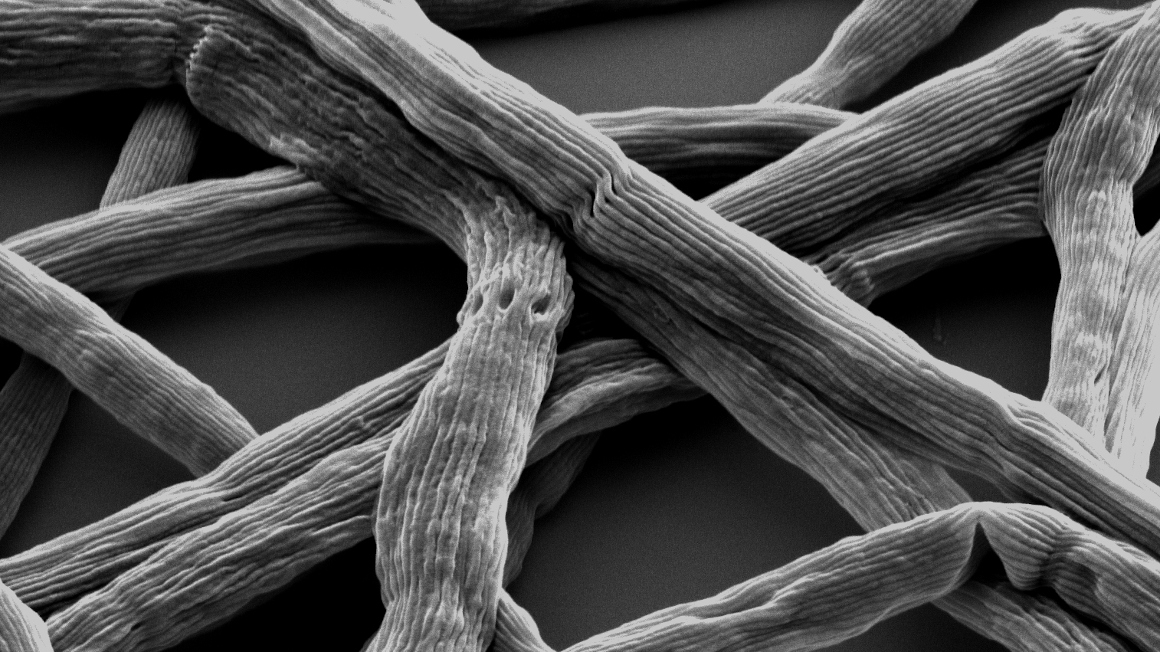

Infinite Roots: Fresh capital for mushroom mycelium technology

The Hamburg-based biotech company Infinite Roots - formerly Mushlabs - has secured 58 million US dollars in a Series B financing round for the development and production of new meat substitutes based on mushroom mycelium.