Biodegradable support structures for 3D printing

A biodegradable support material for 3D printing was developed at the University of Stuttgart from the bioplastic PHBV and common salt.

From prostheses to children's toys, car parts or sporting goods: The possible applications of 3D printing seem limitless and show how popular this technology has become. The range of plastics used in this process is constantly growing, and with it the potential to manufacture bio-based products from them. However, in order to print highly complex three-dimensional objects, so-called support structures are often required.

After printing, these can be removed with solvents or even water. However, depending on which plastic was used as a support material, microplastics can end up in wastewater and thus in the environment. To prevent this, researchers at the Institute of Plastics Technology (IKT) at the University of Stuttgart have developed a support material in the AquaLoes project that is biobased and biodegradable. The new material is based on the bioplastic polyhydroxybutyrate-co-valerate - PHBV for short. This consists of plant-based raw materials such as sugar, starch or corresponding residual and waste materials and is produced biotechnologically with the aid of bacteria. PHBV is completely biodegradable in wastewater and seawater, but is not water-soluble.

Mixture of PHBV, PEG and common salt

The researchers solved the problem of the lack of water solubility of the support material in the project by enriching PHBV with common salt. This method succeeded in breaking down the support polymers in water into tiny fragments, which, according to the researchers, can either be filtered out or, if they remain in wastewater, degraded by microorganisms in manageable periods of time. "Due to the small particle size, we expect a degradation time of a few months," explains project manager Christian Bonten from IKT.

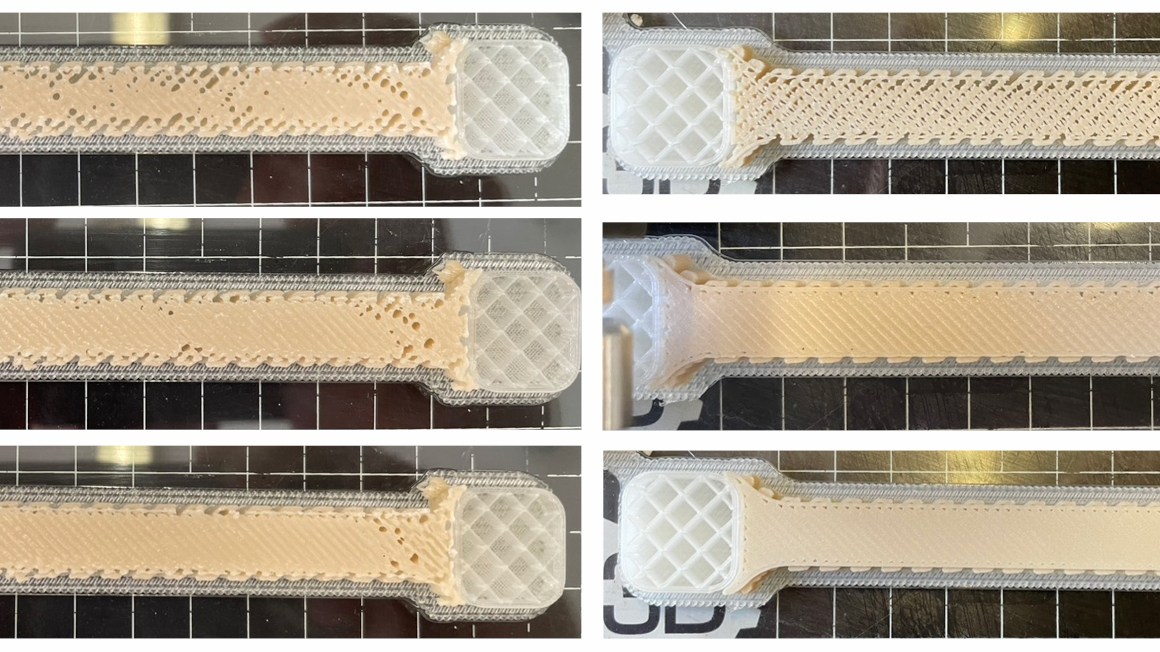

More than 30 different formulations of PHBV, salt and other biodegradable polymers were tested to prove feasibility. In the end, the most convincing result came from a blend of 40% PHBV, 10% polyethylene glycol (PEG) and 50% ultra-fine table salt. "From this compound, it was also possible to print filigree support structures without tearing off the filament strand," the researchers report. In tests with the 3D printing polymer PLA, the printing result was indeed convincing. However, due to the high adhesion, the new support material was initially difficult to remove.

New 3D printing support polymer for hobby sector

Since the development of the novel polymer for 3D printing is aimed at the hobby sector, the team was looking for a process that could be easily implemented in the household. The solution: A standard household dishwasher was used to rinse the printed component and quickly remove the support material.

The novel 3D printing support material made of PHBV, salt and other polymers already has a patent pending. However, improvements are still needed so that the biodegradable support material can survive on the market. The researchers are therefore looking for partners from industry to further develop the approach.

bb