Use enzymes as foams

As a novel class of materials, biocatalysts are particularly durable and active.

Enzymes are at the core of biotechnology. As biocatalysts, they are supposed to help the chemical industry to move away from environmentally harmful processes and to enable particularly sustainable processes. Researchers at the Karlsruhe Institute of Technology (KIT) have now transformed the enzymes into a new form: As foams, the biocatalysts prove to be extremely stable and active. The experts report on their development in the journal Advanced Materials.

Full enzyme foams have higher activity

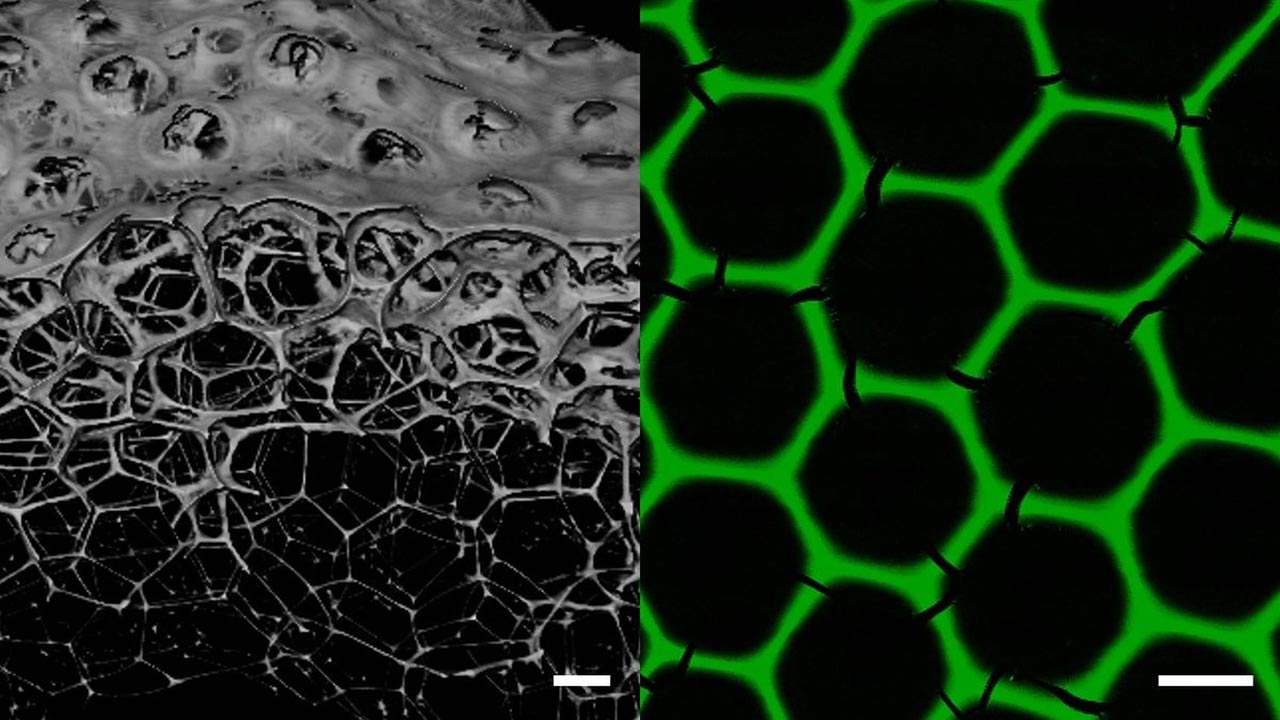

If enzymes are foamed, they normally change their structure and thus lose their specific function. However, the KIT team has developed a method, for which a patent has since been filed, that circumvents this problem. The foam has a uniform bubble size of about 160 micrometers in diameter. "These are monodisperse 'full enzyme foams', i.e. three-dimensional, porous networks consisting exclusively of biocatalytically active proteins," says Christof Niemeyer of KIT, describing the composition of the new materials.

Until now, enzymes have usually been immobilized on polymers or carrier particles. This meant that the actual reaction could only take place in part of the bioreactor volume. "Compared to our already developed 'full enzyme hydrogels', the new foam-based materials create a significantly larger surface area where the desired reaction can take place," Niemeyer explains.

More stable than enzymes without foams

This not only increases the density of the enzymes and thus the possible speed at which the biocatalysts can convert a substance, but also results in an advantage for the application: "Surprisingly, the newly developed enzyme foams are significantly more stable after four weeks of drying than the same enzymes without foam," reports Niemeyer. This is of great interest for marketing, he says, because it simplifies storage and shipping considerably.

In a practical test, the team showed that its enzyme foams can be used to produce the sugar tagatose. It is considered an interesting industrial alternative to refined sugar. However, according to the researchers, enzyme foams can be used anywhere in biotechnology to make processes more efficient - from industrial biotechnology to food biotechnology and materials science.

bl