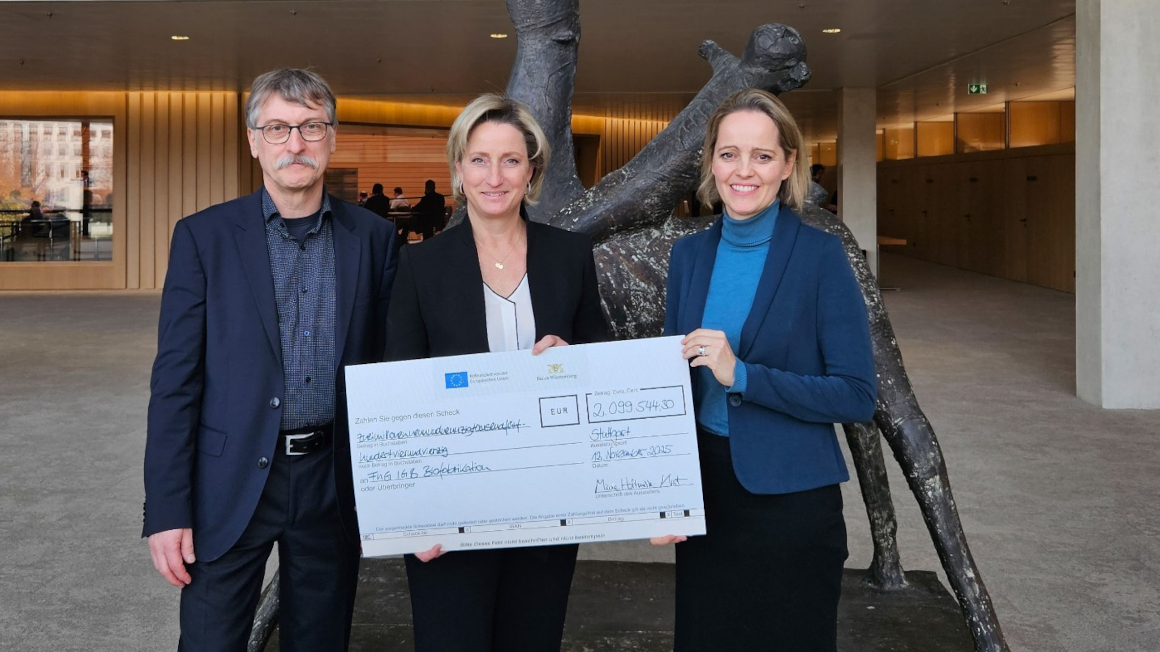

Biological PET recycling: start-up founded

The discovery of the PHL7 enzyme was the starting point for the founding of the Leipzig-based start-up ESTER Biotech.

PET (polyethylene terephthalate) is a plastic based on fossil raw materials such as crude oil or natural gas. Although pure PET is fully recyclable, it often ends up in the environment or is incinerated. Biochemists Dr Christian Sonnendecker and Dr Ronny Frank are focusing instead on a biological recycling process using PHL7.

Closed recycling loop possible

The PHL7 enzyme, which was discovered in 2022, can break down PET into its original components - terephthalic acid and ethylene glycol - by more than 90% within 16 hours in a reactor. These monomers can be processed directly back into new PET - making a closed recycling loop possible. Based on these research results, the two biochemists from Leipzig University developed a business idea and founded the company ESTER Biotech.

Optimisation through artificial intelligence

In order to make the process commercially viable, the researchers rely on machine learning and a measurement technology developed by Ronny Frank. "This has enabled the enzyme to be significantly optimised: It works faster, more stably and more efficiently," he explains. The customised PHL7 variant is intended to enable more resource-efficient recycling of plastic waste. However, further optimisation is required for practical use. For this reason, a larger reactor is currently being built that can process more PET - a further step on the way to more sustainable recycling on a large scale.

lh