Optimising protein structures with AI

Under the leadership of the Technical University of Munich, an international research team has developed a method with which proteins can be designed even better on a computer and produced with the desired properties.

Alongside fats and carbohydrates, proteins are the main nutrients that the human body needs. Proteins serve as a building material for cells and tissue, can repair bones and tissue or control metabolic processes in the body as an enzyme. Researchers have therefore been endeavouring for years to recreate proteins on the computer and give them better properties. An international research team led by the Technical University of Munich (TUM) has now developed a new method for designing proteins.

In addition to TUM, researchers from China and the USA were also involved in the project.

Protein design with Nobel Prize software

According to the researchers, they also utilised the capabilities of the AI-based software AlphaFold2 for their work. Its developers, Demis Hassabis and John Jumper, were honoured with the Nobel Prize in Chemistry this year. The software makes it possible to predict the structure of so-called de novo proteins with high accuracy on the computer.

As the team reports in the journal Science, the new protein design method combines ‘the accurate structure prediction of Alphafold2 together with a gradient descent approach’ for efficient protein design. Gradient descent is an established method for model optimisation, with the help of which deviations from the desired target function of the proteins can be made visible and the parameters can be adjusted step by step until the optimum result is achieved. The researchers report that the protein structure of new proteins predicted by AlphaFold2 could thus be compared with the desired protein structure.

Protein structure virtually optimised

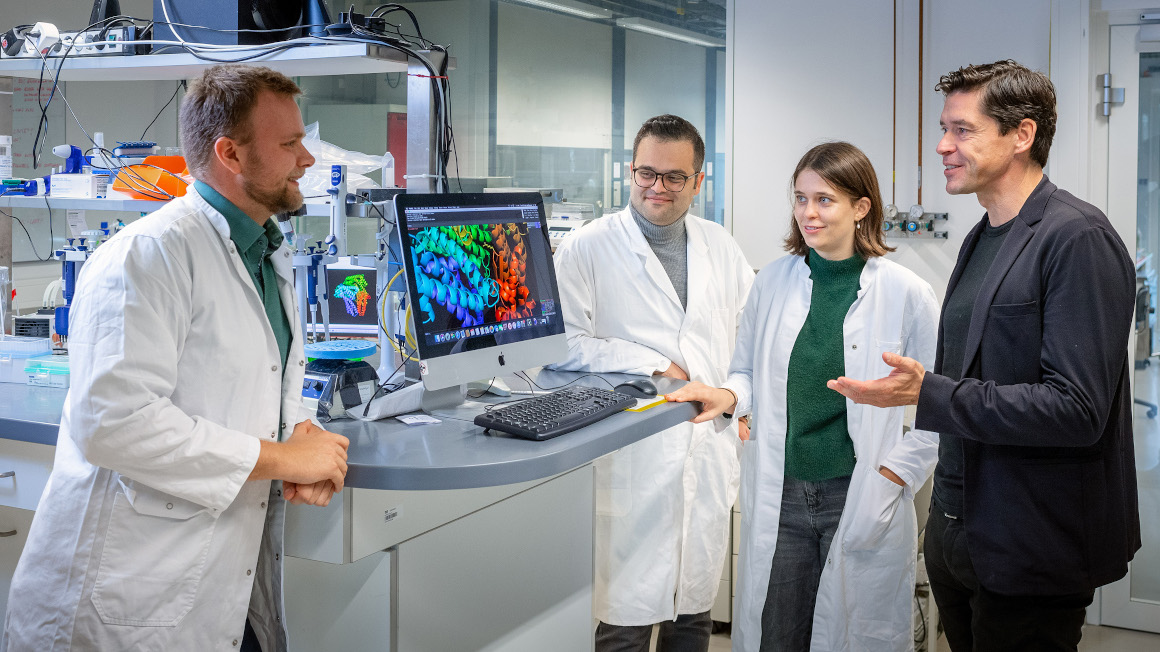

This allowed them to virtually optimise the newly designed amino acid chains and the structure that is crucial for the stability and function of the protein. ‘Over several repetitions, we improve the arrangement of the amino acids until the new protein is very close to the structure we would like to have,’ says Christopher Frank, PhD student at the Chair of Biomolecular Nanotechnology and first author of the study. This optimised structure can then be used to determine the sequence of amino acids that can actually be implemented in the laboratory.

Proteins designed with up to 1,000 amino acids

The team led by Munich-based molecular biologist Hendrik Dietz has already proven that the method works in practice: According to the study, over 100 proteins were not only virtually designed using the new method, but also produced in the laboratory and tested experimentally. ‘We were able to prove that our designed structures correspond very closely to the real implementation,’ says Christopher Frank. Proteins were designed that contain up to 1,000 amino acids. ‘This brings us close to the size of antibodies and - as with antibodies - we can then integrate several desired functions into such a protein. These could be, for example, motifs for recognising and suppressing pathogens,’ adds Dietz.

bb