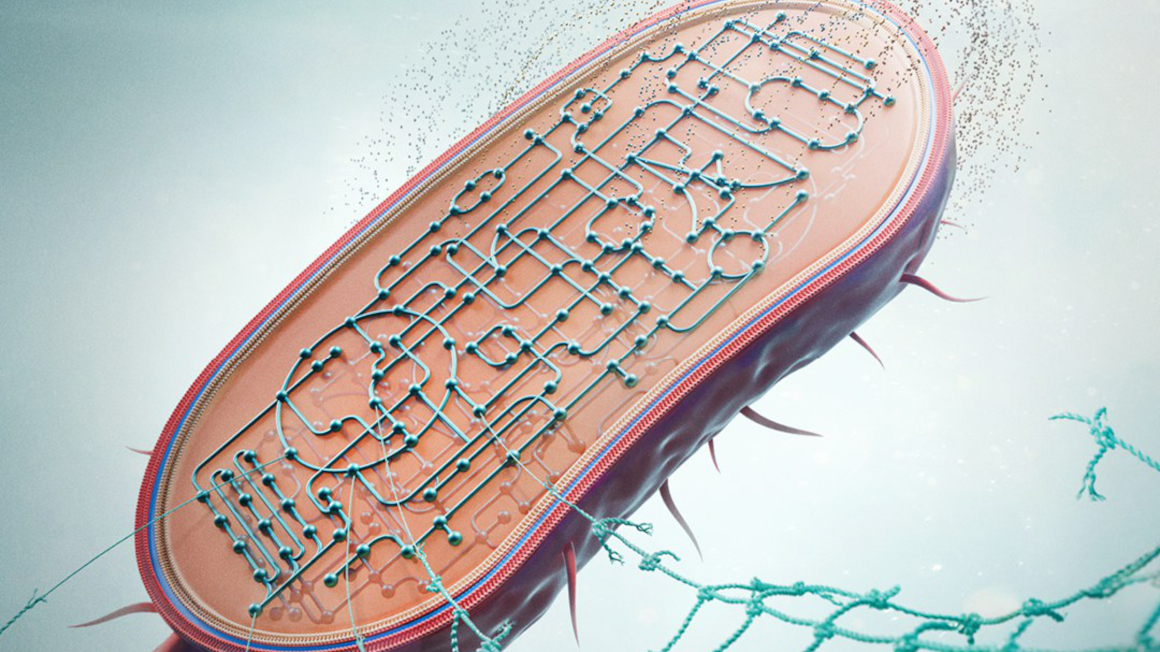

When you think of fuel cells, you don't necessarily picture bacteria. However, microorganisms also need energy for their metabolism and obtain it through electrochemical processes. Excess electrons are released into the environment by the unicellular organisms. Biotechnologists want to take advantage of this fact to drive microbial fuel cells. The project "Textile Carbon Electrodes for Microbial Fuel Cells" (TexKoMBZ) has developed a special anode that makes future industrial-scale applications seem realistic.

Bacteria like carbon electrodes

"Microbial fuel cells use carbon electrodes. Bacteria like that, because they are very biocompatible," explains biotechnologist Miriam Rosenbaum, who headed the project at RWTH Aachen. The challenge is to design the bioanode in such a way that the bacteria have as large a surface area as possible for interaction and at the same time achieve a high packing density. So far, microbial fuel cells have failed because their energy density is not sufficient to allow economic processes on an industrial scale.

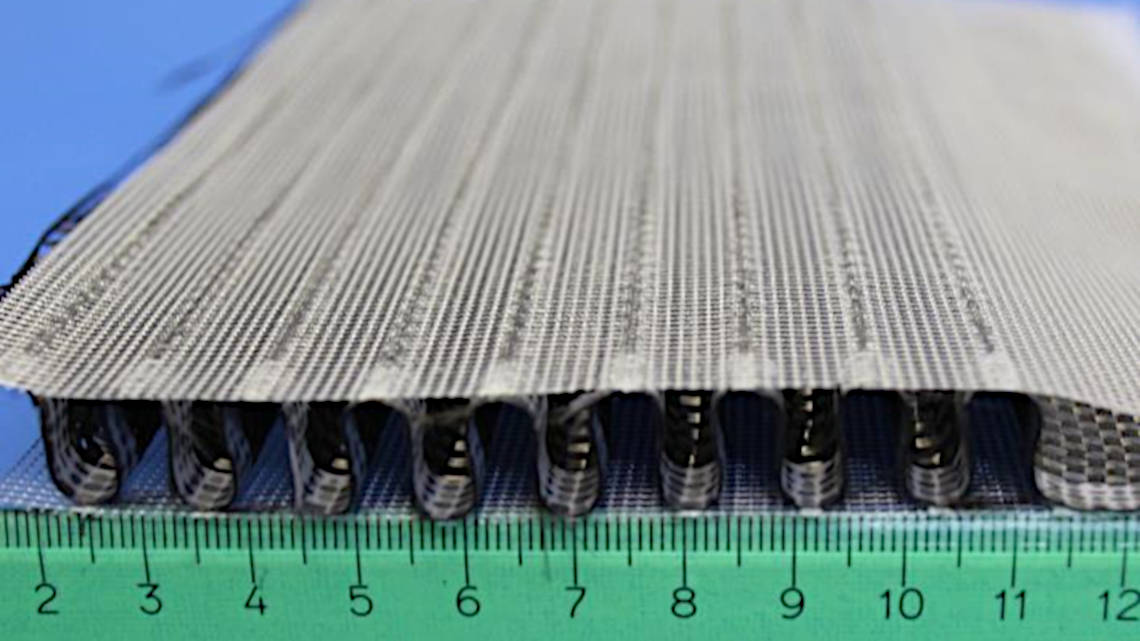

The TexKoMBZ project therefore focused on carbon fibre-based textile materials on which the bacteria are to grow. These textile materials have a high specific surface area, good electrical conductivity and exhibit both stability and flexibility. Last but not least, their porosity can be easily adjusted, as the waste water has to reach the electrode. However, these materials usually also have a plastic protective layer, which would not be suitable for the desired function and therefore requires adjustments. "The exciting question was: Can we tailor bioelectrodes with it," says Rosenbaum, describing the challenge. This is "very, very complex" mainly due to the scaling.

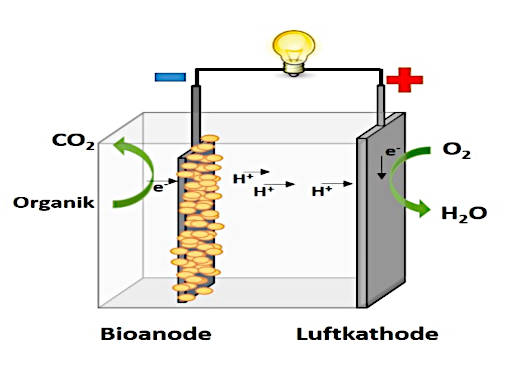

Schematic of a biofuel cell

Fuel cell makes oxygen fumigation superfluous

However, good scalability was essential, as the researchers had in mind wastewater treatment as a field of application. Even today, bacteria have the task of degrading organic residues in wastewater treatment plants. To do this, the microorganisms need oxygen to get rid of excess electrons from biochemical reactions. Using a lot of energy, this oxygen has to be blown into the wastewater, which is usually low in oxygen. If a fuel cell were to remove these electrons from the bacteria, it would not only be possible to save a lot of energy when supplying oxygen, but it would also be possible to generate electricity. "A sewage treatment plant could then work almost energy neutrally," is the vision of Rosenbaum and her colleagues. Last but not least, there would be less sewage sludge because the bacteria would multiply more slowly as they would release part of their energy.

"We have developed various designs, simulated and tested their flow dynamics and observed the activity of the bacteria on 2D anodes in the laboratory," Rosenbaum describes the first steps. Different shapes and weaving patterns were used, including 3D structures in certain clamping frames. The researchers were always excited about the test with model organisms: How reactive is the anode this time? At the end of the laboratory tests, there was a textile anode that fully met the requirements.

Anode successful, cathode remains problem

The next step was to test the new electrode with waste water on a two-litre scale. Then things got serious and the researchers installed a 20-liter reactor in the wastewater treatment system of a paper mill. While the anode had shown good results in the laboratory, the overall system of the fuel cell failed in practice. "The anode product was a success, but the cathode quickly becomes dysfunctional," sums up Rosenbaum. The oxygen in the water is only reduced very slowly on the cathode. Platinum could accelerate this, but the catalyst needs a clean environment, otherwise it quickly becomes poisoned and ineffective. The team has tested numerous cathode variants - without any notable success. "This requires a different level of expertise than we had," stresses Rosenbaum, "but we knew beforehand that this could become a problem. That's why the project concentrated on the anode from the very beginning. In two years' time, more could not have been achieved, the project manager knows from experience.

Project Consortium

Project partners

iAMB – Institut of Applied Microbiology, RWTH Aachen University

IMH – Institute for Modelling and High Performance Computing of the University of Applied Sciences Niederrhein

ISA – Institute for Urban Water Management at RWTH Aachen University

Institute for Textile Technology Augsburg gemeinnützige GmbH (ITA)

Heimbach GmbH & Co. KG

Associated Partners

CARBO-TEX GmbH, CM Consult, Güth & Wolf GmbH, Mainsite Technologies GmbH, Rhein Papier GmbH UPM Hürth

New field of application for textile bioanodes

New field of application for textile bioanodes

She is nevertheless satisfied with the result, because the consortium has achieved the project objective of a functioning, sufficiently reactive textile anode made of carbon fibres. "The project has shown that such anodes can be tailor-made," said the biotechnologist. It is still unclear whether the development of a microbial fuel cell for sewage treatment plants will continue. With her new team at the Leibniz Institute for Natural Product Research and Infection Biology, she plans to further develop the textile electrodes, this time for use in bioreactors where other requirements for the cathode are met.

The TexKoMBZ project was funded from 2016 to 2018 by the Federal Ministry of Education and Research with a total of 778,000 euros as part of the "New Products for the Bioeconomy" funding measure.

Björn Lohmann