Veganz relies on Fraunhofer indoor farming system

For the cultivation of food crops, Veganz, a company specializing in vegan foods, has secured the licensing rights to the vertical farming technology developed by Fraunhofer IME.

Already to be found in some supermarkets: glass mini-farms in which lettuce or herbs grow on several floors in a special nutrient solution without pesticides under LED light and are sold freshly harvested directly on site. This controlled and resource-conserving plant cultivation in so-called vertical farms is not only sustainable, but the yields are also significantly higher, according to experts. For companies in the food industry, urban plant cultivation thus opens up entirely new opportunities. Veganz Group AG, known for vegan pea-based foods, has now secured the worldwide licensing rights for growing food crops in the OrbiPlant and OrbiLoop vertical farming systems developed by the Fraunhofer Institute for Molecular Biology and Applied Ecology IME.

Large scale indoor cultivation

What is innovative about the Fraunhofer Vertical Farming Platform technology is that, for the first time in the world, it enables the cultivation of staple foods on a large scale in a regionally and economically viable manner. What is also new is that the technology can be "directly coupled with the processing industry" and thus "enables the complete value chain from cultivation to finished food." "With our approach of direct industrial utilization of the cultivated products, we not only create the basis for a profitable business model, but also achieve local food security for the basic supply of the population with healthy, plant-based proteins and carbohydrates through the cultivation and production of plant-based staple foods, regardless of the environmental and climate conditions in any place in the world," says Jan Bredack, founder and CEO of Veganz Group AG. To use the Fraunhofer platform technologies, Veganz will make the production plant for manufacturing structured plant protein for pea-based meat alternatives correspondingly modularly adaptable and available as an overall concept, they say.

Conveyor belt plant cultivation

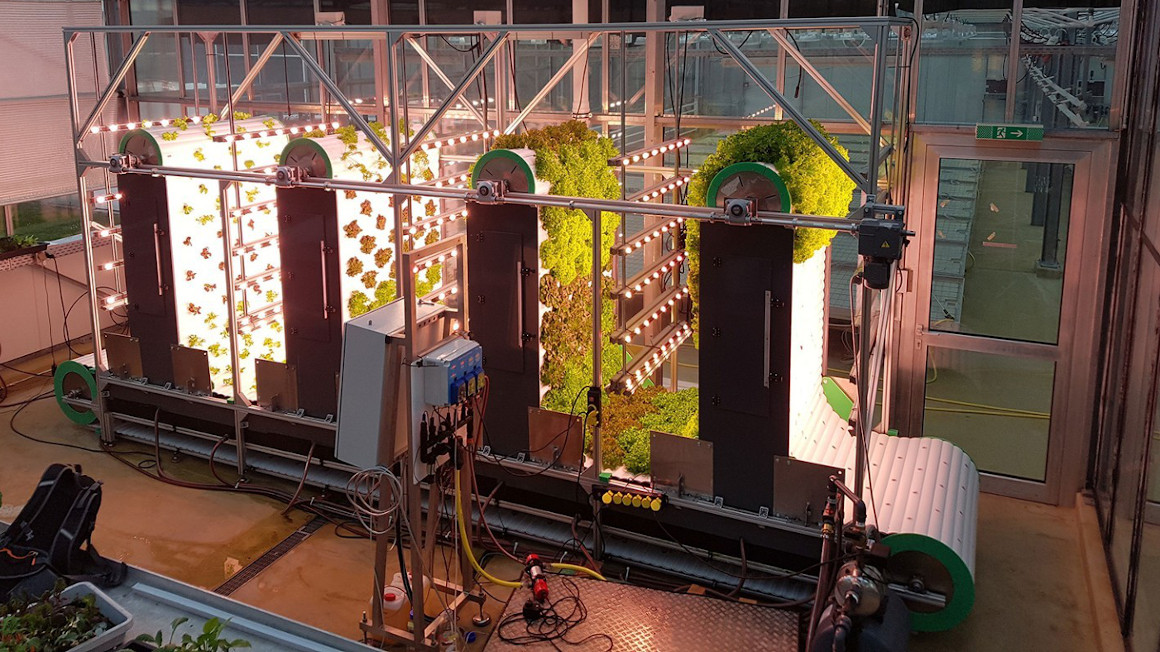

Unlike previous indoor farming methods, the OrbiPlant technology uses an integrated, wave-shaped conveyor system that fixes and continuously realigns the respective plants in space. This, researchers say, increases the production of certain plant hormones, resulting in faster leaf growth and higher biomass. In addition, the system features an aeroponic irrigation system, in which plant roots are suspended in the air and supplied with targeted water and nutrients via a spray. During cultivation, optimal exposure of the plants through modular LED technology and additional CO2 fertilization ensure higher quality and yields.

OrbiLoop, the compact InStore version of OrbiPlant, also works according to this principle. Unlike OrbiPlant, here the plant growing system rotates continuously in a single conveyor loop. This smaller vertical farming system can be placed in supermarkets or restaurants for self-sufficient plant production - without the need for special expertise. According to the researchers, the cultivation area can also be flexibly adjusted in height and width as needed.

Door opener for worldwide indoor production

"We are pleased that our patented OrbiPlant and OrbiLoop vertical farming platform technology now acts as a door opener for the global industrial production of food crops under highly efficient indoor conditions, which is an important building block for the agricultural and nutritional turnaround against the backdrop of advancing climate change," says Andreas Reimann of Fraunhofer IME, announcing that the existing research cooperation "will be expanded with a view to opening up and optimizing the vertical farming production process for further food crops."

bb