Food and beverage industry

The food and beverage industry plays a prominent role in bioeconomy. This industry processes raw agrarian materials to foods, beverages and animal fodder. Resource-conserving technologies help to manufacture healthy, high-value and safe products. For storage, preservation and transport of food and beverages, the bio-based economy also provides innovative processes.

FACTS & FIGURES

No. of companies:

5.800

Employees:

570.000

Sales:

€170 billion

(Source: BVE 2015)

Examples of bioeconomy:

Vitamins, aromas and amino acids,

lupin ice cream, functional foods

With around 6,000 companies and 555,000 employees, the food and beverage industry is one of the largest German industrial sectors. According to the Federation of German Food and Drink Industries (BVE), total sales for 2012 were almost 170 billion euros, a European record. This sector is especially characterized by small and medium-sized enterprises, since 95 % of sector companies have fewer than 250 staff. These firms include many traditional family companies and internationally successful manufacturers of German specialties that are closely connected with company locations.

Leading sub-sectors of the food and beverage industry are the meat and meat-products industry, the dairy business, the sweets and bakery-products industry, the manufacture of alcoholic and non-alcoholic beverages and the processing of fruits and vegetables. These activities are reflected by the great diversity of products: more than 170,000 food and beverage products are currently on the market.

For the bioeconomy, the food and beverage sector is a key pillar, since about 80 % of agrarian products in Germany are processed by the industry to high-quality food and drinks (see section “Agriculture and forestry”). Innovative processes for production of high-value ingredients additionally provide an important contribution to making food healthier and safer. Resource-saving processes provide new and more sustainable materials and forms of packaging. Increasingly important, furthermore, are strategies that recycle waste products from the human-food and animal-fodder industries. As a result, the food and beverage industry is not only currently the user of agrarian raw materials, but in future can itself become increasingly a supplier of raw materials – for example, for the chemical industry (see section “Chemistry).

For food processing, resorting to nature’s toolbox is not a new phenomenon. Indeed: beer has been brewed and wine produced for thousands of years with the aid of the baker’s yeast Saccharomyces cerevisiae. Cheese likewise represents a traditionally bio-based product. For milk to turn to cheese the milk protein must coagulate – for which rennet enzymes are responsible. In earlier times, rennet was obtained from calves’ stomachs. Thanks to advanced biotechnological processes, tailored microorganisms in large steel vessels today carry out the industrial production of these useful molecules, which are now an indispensable part of cheese production.

Biotechnologists are also responsible for the fact that many foods today contain enzymes as natural biocatalysts. Since the 1960s, microbial processes in fermenters have become established as standard in the production of enzymes. Currently, approximately 50 different industrial enzymes are in use in the food and beverage industry. Around 30 biotechnology companies in Germany – all of them small and medium-sized enterprises – have specialized in developing and implementing the resulting production processes. A number of these companies have had part of their technological development work funded by the BMBF and the Federal Ministry of Economics.

Enzymes have by now become indispensable in the bakery industry. They assure attractive crusts and aid in finishing off parbaked products.

Enzymes are resource-friendly multi-talents as manufacturers of food products, since they carry out their work under moderate conditions. In the bakery industry, special enzymes assure attractive and stable bread crusts. Other enzymes in bakery mixtures aid in giving the dough volume and colour. The finish-baking of partially prepared parbaked dough, now widespread, would not be thinkable without such enzymes. Enzymes allow physiological enhancement and more efficient use of other raw food materials.

In this way, pectic enzymes aid in breaking down the plant cell walls when fruit is squeezed out, which increases the juicing yield – and they likewise degrade turbidity material in fruit juices. Other biological processes such as lactic acid fermentation help in the predigesting of animal fodder and human food: for example, in the production of sauerkraut and silage in animal fodder. Lactase is also an important enzyme in the food sector: it enables breakdown of lactose. This enzyme is sold in the form of tablets and capsules to enable humans with lactose intolerance to consume dairy products.

Mother’s milk is the ideal natural nourishment for babies. In addition to nutrients, it contains a rich mix of goodness – including human milk oligosaccharides. These complex polysaccharides support the development of healthy intestinal flora in infants and protect them from infection by pathogens. Medical experts assume that sugar molecules intercept viruses and bacteria that enter the gastrointestinal tract before they can attack a baby’s cells. As a result, the World Health Organization recommends breastfeeding babies until their sixth month. Where this is not possible, baby formula can serve as alternative. The makers of such products have an ongoing interest in continuous improvement of their formulas. Researchers at the company Jennewein Biotechnologie GmbH in Rheinbreitbach, Germany, have accordingly developed a process that allows biotechnical production of human sugar molecules.

Microbes transformed to mini-factories in this way produce fucosyllactose – a sugar molecule that occurs in nat-ural mother’s milk. The BMFB funds this family-run company by its measure KMU Innovativ (SME Innovative).

Enzymatic and fermentation processes also extensively serve as basis for production of natural aroma agents. Numerous flavouring agents are likewise manufactured with the aid of microorganisms. Mushrooms that grow on wood shavings, for example, produce strawberry aroma. Peach aroma is extracted from yeast. The first food additive biotechnologically produced on a large scale was citric acid. Whereas this substance was originally obtained from citrus fruits, the entire world production, to the amount of a billion tons annually, presently stems from a process using the fungus Aspergillus niger. Citric acid is used not only in lemonade drinks, but also wherever a sour taste is intended. An additional important group of food supplements is also biotechnologically produced: amino acids. There are approximately 20 amino acids, and they form the building blocks of which proteins consist. Some amino acids provide a sweet taste, and others add the fragrance of oranges or lemons. The salts of glutamic acid (glutamate) are used in turn as flavour enhancers – and not only in Asian cuisine. The bacterium Corynebacterium glutamicum aids in the production of glutamic acid on an industrial scale. Essential amino acids such as lysine, threonine and methionine are also of great importance as additives to animal fodder. Currently, more than one billion tons of lysine is internationally produced for the fodder industry. Such large amounts can be handled by chemical processes only at very great cost. As a result, bacteria re-programmed especially to function as cell factories are now likewise used here in production. The company Evonik is one of the largest producers of amino acids for animal fodder. This specialist chemical group, with headquarters in Essen, Germany, manufactures the four essential amino acids methionine, threonine, tryptophan and lysine. It is currently appreciably expanding its capacities around the world. Evonik is now aiming at annual production of more than 500,000 tons of biotechnologically obtained amino acid L-lysine.

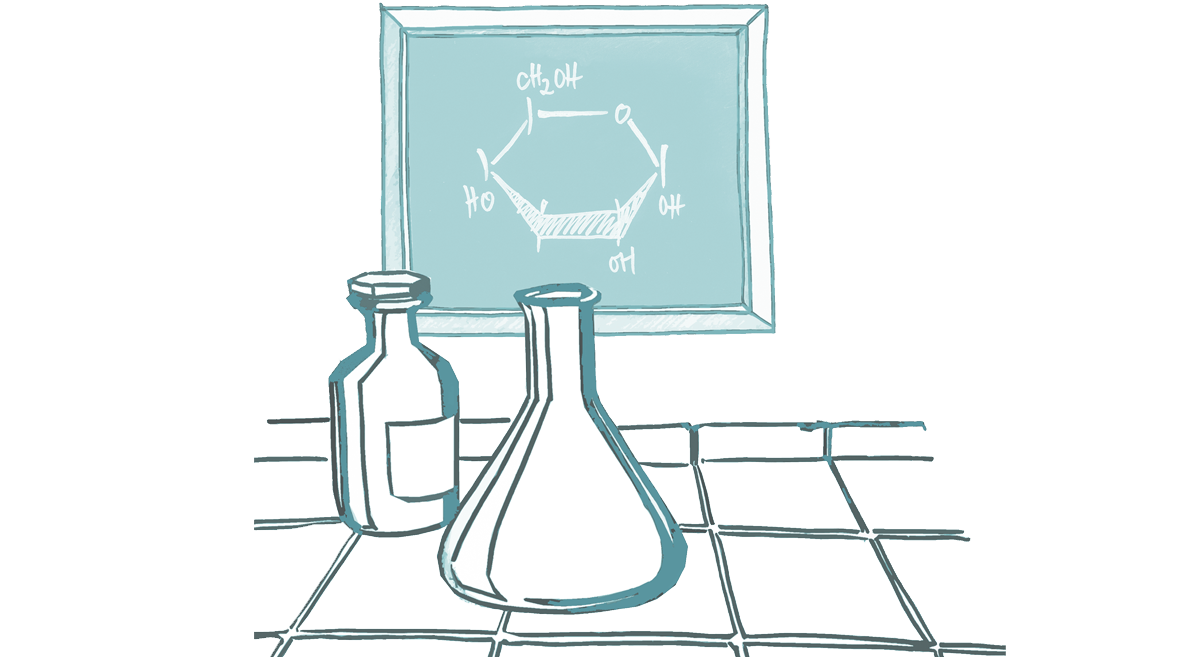

Even greater roles on the market are played by enzymatically produced carbohydrates such as glucose and fructose that are used as sugar substitutes. Glucose can be obtained from plant starch by enzymatic hydrolysis. Trends are also apparent toward use of sweeteners with fewer calories that less likely trigger civilization diseases such as obesity. Substances are in demand that taste sweet but that contain no sugar. Such an alternative is an extract from the tropical plant Stevia rebaudia, which already sweetens food and beverages without calories.

Stevia: alternative to conventionel sugar.

The so-called steviol glycosides are almost 200 times sweeter than conventional sugar. Experiments are currently in progress on the production of stevia sweeteners by biotechnological processes. With the aid of yeast cells, the individual constituents of stevia sweetener can be separately produced with great purity in controlled and monitored fashion. The food industry has thereby enabled the possibility of varying stevia taste in accordance with application, and of entering new areas of use for this sweetener.

In the food and beverage sector, functional foods represent a further trend for which bio-based processes can prove useful. This development concerns products that have positive and above all prophylactic influence on health owing to special bioactive ingredients. Prebiotic substances, for example, are considered to be functional constituents, which include special dietary fibre that has positive effects on intestinal flora. Probiotic dairy products, in turn, contain specially bred and vital strains of bacteria that, ingested with food, help to maintain balance among intestinal flora. In order, however, that food and beverage producers can make health-related claims for their products, they must provide scientific evidence of efficacy in accordance with the EU Health Claims Directive: a complicated and expensive procedure.

Certain phytochemicals such as polyphenols and glucosinolates are likewise considered candidates as health-promoting constituents. As such, their effects can include reduction in the risk of malignant disease, regulation of blood pressure, lowering of blood cholesterol level and strengthening of the immune system. In addition, they can demonstrate antibacterial, antiviral and anti-inflammatory effects. BMBF-funded research projects in Germany are currently investigating how polyphenols can be cost-effectively obtained from citrus fruits, and how glucosinolate content can be increased in broccoli. Retailers are already offering an unusual combination of seafood and meat: one supermarket chain offers sausage types that have been enriched with omega-3 fatty acids from fish oil. Food researchers from the Fraunhofer Institute for Process Engineering and Packaging (IVV) have developed these products to the point of marketability.

Nutritional science has recently been more closely examining alternative protein sources, in efforts toward more sustainable development of domestic agriculture and at the same time toward reduction of the consumption of animal protein. The lupin is one of the most striking protein plants in Germany; its seeds have a protein content of 35 %. Until now, however, the high content of bitter constituents has prevented lupin use in the food industry. Decades ago, researchers discovered that the blue lupin (Lupinus angustifolius) was a species that contains little alkaloids and is resistant to many plant diseases.

In addition, the legume is relatively undemanding and thrives very well, especially in Northern Germany. In its storage of nitrogen, the lupine improves soils and requires no fertilization. To assess the market opportunities of innovative lupin-protein products, the BMBF funded in the state of Mecklenburg-Western Pomerania the project Regional Growth Core PlantsProFood: Food from the Blue Lupin. Partners in this innovation initiative were ten companies and four research institutions in the Rostock vicinity – including researchers from Fraunhofer IVV and the split-off company ProLupin GmbH in Neubrandenburg, which by now have developed various lupin-based food sorts.

Lupin seeds are a rich source of protein. Vegan ice cream with a creamy consistency can be produced from them.

The first commercial product has been ice cream, which is now available in supermarkets. In addition to lupin proteins, it contains rapeseed oil, additional plant constituents as well as polyunsaturated fatty acids. This ice cream is interesting for vegetarians and for allergy sufferers. Lupin proteins have also been processed in a vegetarian liverwurst, in which proteins replace most of the fat: whereas a conventional liver sausage has 30 % fat, the lupin sausage has only 5 %. The BMEL also funds an alliance project that is experimenting with how innovative foods can be manufactured from other domestic legumes: for example, from peas and field beans.

In the food and beverage industry, there is a great deal of untapped potential for bioeconomy in heretofore discarded parts of food. One example is citrus albedo, the white layer of tissue in citrus fruits. Until now, it has been considered waste by the industry, usually with no further use. Researchers from the college Hochschule Ostwestfalen-Lippe are working to produce a natural opacifying agent from the albedo. These substances would be added to lemonade to preserve its murkiness. With several industrial partners, the biotechnologists engaged here are developing an enzymatic process to enable extraction of the suitable constituents from the albedo layer. In the bakery industry, many tons of waste accumulate every year. These remnants represent valuable organic resources for researchers at the Leibniz Institute for Agricultural Engineering Potsdam-Bornim. In an EU project, they also want to use stale buns to obtain molecular building blocks for bioplastics from which bags can be produced. The use of waste in the food and beverage industry is therefore an example in the bioeconomic cycle of how various sectors can, through interlinking, more efficiently use resources and thereby contribute to greater added value for Germany as an economic location.