Watching mold cultures grow

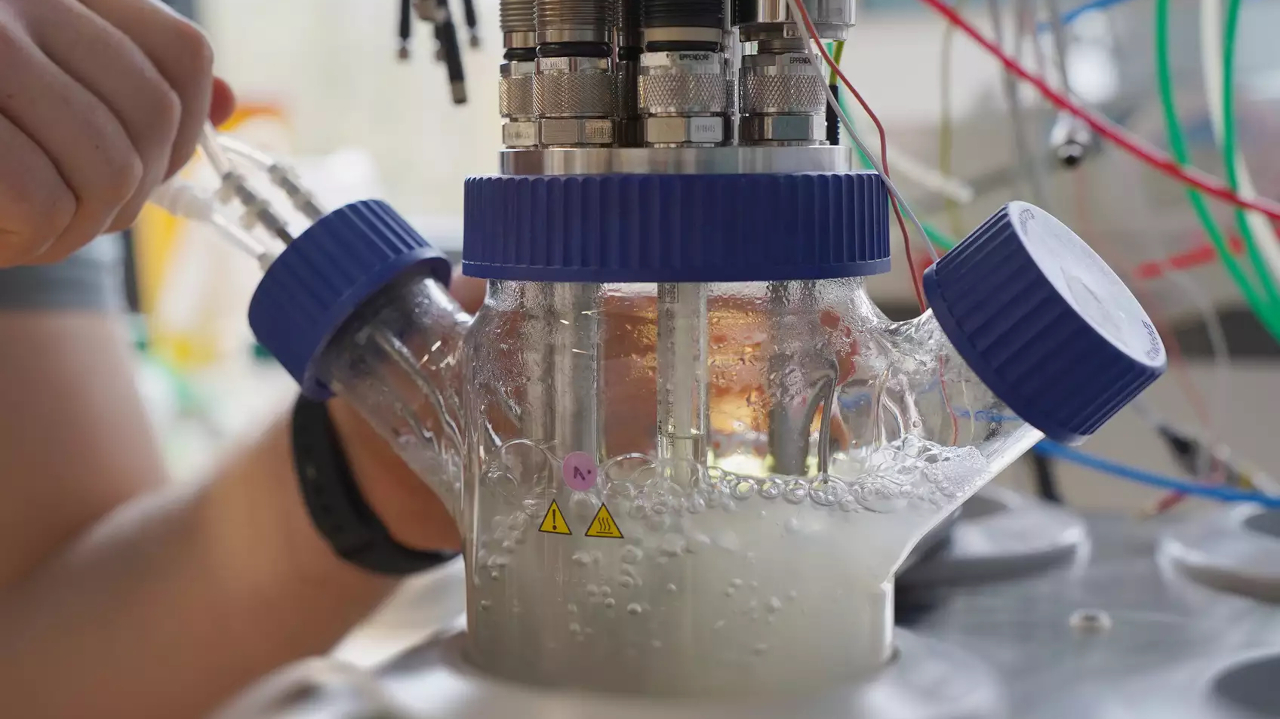

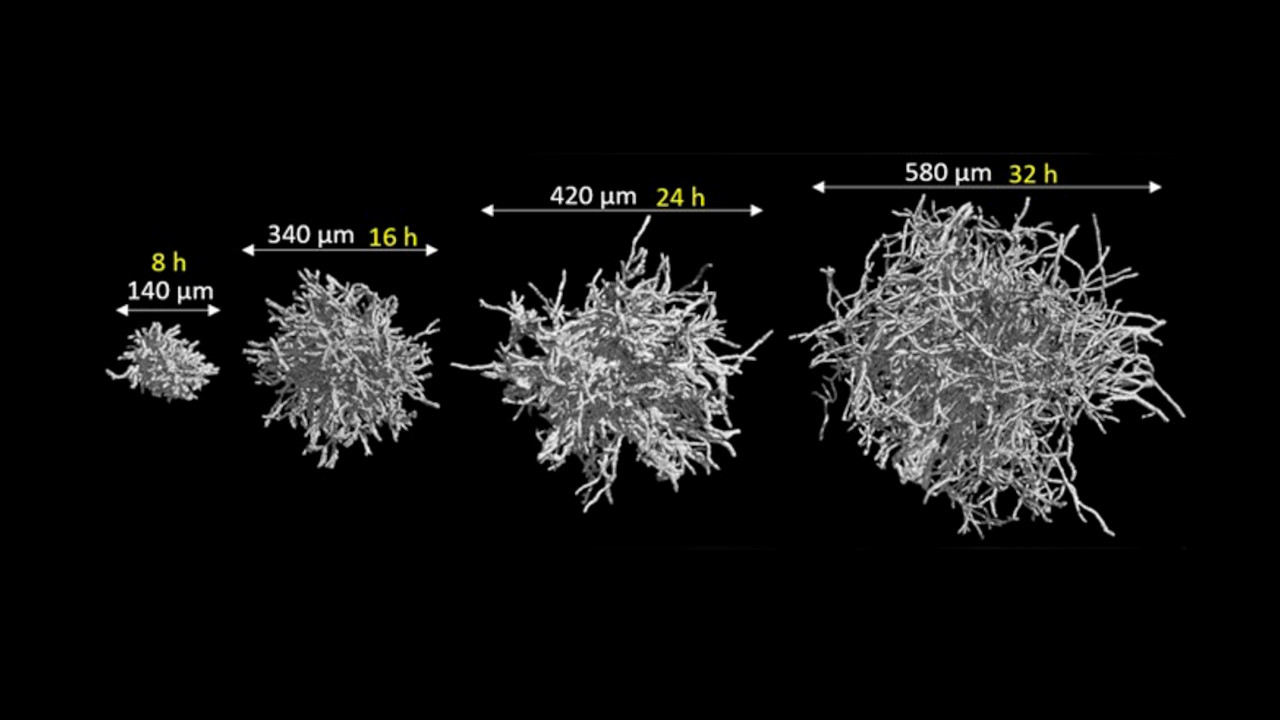

Using micro-computed tomography, a research team has succeeded in observing the growth of mold cultures in the bioreactor in 3D.

Molds are not only a health risk. They are also important microbial cell factories in biotechnology. The first process of this kind was the fermentation of citric acid more than 100 years ago. In the present, numerous other acids, enzymes and pharmaceutically active molecules have been added. How productive these manufacturing processes are also depends on the spatial structure of the fungal tangles in the bioreactor. A German research team has now succeeded in analyzing these structures.

Problem: Too few cells for representative statement

If researchers want to map the complete 3D structure of a mold in detail, there is only one ideal method: micro-computed tomography. Although numerous laboratories have the necessary equipment, what allows statements about a single fungal cell says little about the condition of a large fungal culture in a bioreactor. Until now, it has simply been impossible to examine a sufficient number of individual cells to make a representative statement about the spatial structures of the entire culture. A team of experts from the Technical University of Munich, the Technical University of Berlin and the Helmholtz Center Hereon has now mastered this challenge. This was made possible by collaboration with another research institution of the Helmholtz Association, DESY.

Solution: Micro-computed tomography with highly brilliant synchrotron radiation

"At Germany's largest accelerator center - the German Electron Synchrotron DESY - we have developed a method based on micro-computed tomography using highly brilliant synchrotron radiation and 3D image processing that makes it possible to continuously follow the continuous development of the shape of an entire fungal culture in a bioprocess at high resolution and in three dimensions," explains Henri Müller of TU München, lead author of the study, which was published in the journal Biotechnology & Bioengineering.

"Thanks to the almost complete automation of data acquisition and image processing, it was possible to examine several thousand fungal hyphae in the present study and thus obtain statistically meaningful measurement data on the growth of fungal cultures," reports Hereon researcher Jörg Hammel.

Approach to improving biotechnological processes

Heiko Briesen of the Technical University of Munich acknowledges the importance of this work: "With the help of micro-computed tomography, we can look at the internal structure of mold pellets in a completely new level of detail." Such data could now be incorporated into models that can predict, among other things, the growth and productivity of molds, the researcher says. This, in turn, would ultimately make it possible to optimize biotechnological processes involving fungal cultures.

bl