New bioplastics to combat pollution

Environmental contamination due to plastic waste is enormous. Nuremberg researchers are developing bio-based and biodegradable plastics to put an end to this.

Plastics, plastic packaging and the resulting waste threatening the environment as well as our health are on everyone's mind at the moment. Almost simultaneously with the first evidence of microplastics in the digestive tract of humans, the European Parliament has approved a ban on disposable plastic articles. As a result, disposable and single-use plastic products could disappear from the market as early as 2021.

Touring exhibition illustrates environmental pollution

A particularly vivid visualisation of environmental pollution caused by packaging waste was presented by the touring exhibition Ocean Plastics Lab. The open-air exhibition, comprising four ship containers, stopped in Berlin from 21 to 29 October. Previous venues include Washington D.C., Ottawa in Canada, Turin, Paris and Brussels. The exhibition is supported by the German Federal Ministry of Education and Research (BMBF), the German Marine Research Consortium and the European Commission.

The Ocean Plastics Lab showcased impressive and interactive examples in order to make plastic contamination tangible for a broad audience. For example, visitors could look through microscopes and discover small pieces of plastic between grains of sand or observe the behaviour of different types of plastic in water - some swim on the surface, others sink to the ground.

Birds serve as indicators of contamination

According to the organisers, 12 billion kilograms of plastic end up in the world's oceans every year. A large percentage of this makes it way into the stomachs of marine animals, which either die because of it or introduce the plastic particles into the food chain. By now the stomach contents of the northern fulmar Fulmarus glacialis is a formal marine litter indicator: The ecologically acceptible level of marine litter in the North Sea should not exceed 0.1 grams of plastic in 10% of beached fulmars. However, recent studies have shown that 58% of the stomach contents exceed this level.

The Ocean Plastics Lab exhibition uses emphatic numbers to illustrates the extent of environmental pollution caused by plastic waste.

The exhibition illustrates the extent of environmental pollution with strong numbers: According to the figures, around 5.25 trillion plastic particles are afloat in the oceans of the world. Much of this stems from packaging, which accounts for 42% of all plastic production. Plastic packaging and other plastics are firmly integrated into our everyday lives and cannot be easily dispensed with everywhere. Stephanie Stute is well aware of this: She is a professor at the Faculty of Process Engineering at the Technical University of Nuremberg and is researching biobased plastics that are also biodegradable.

Bio-based as well as biodegradable plastics

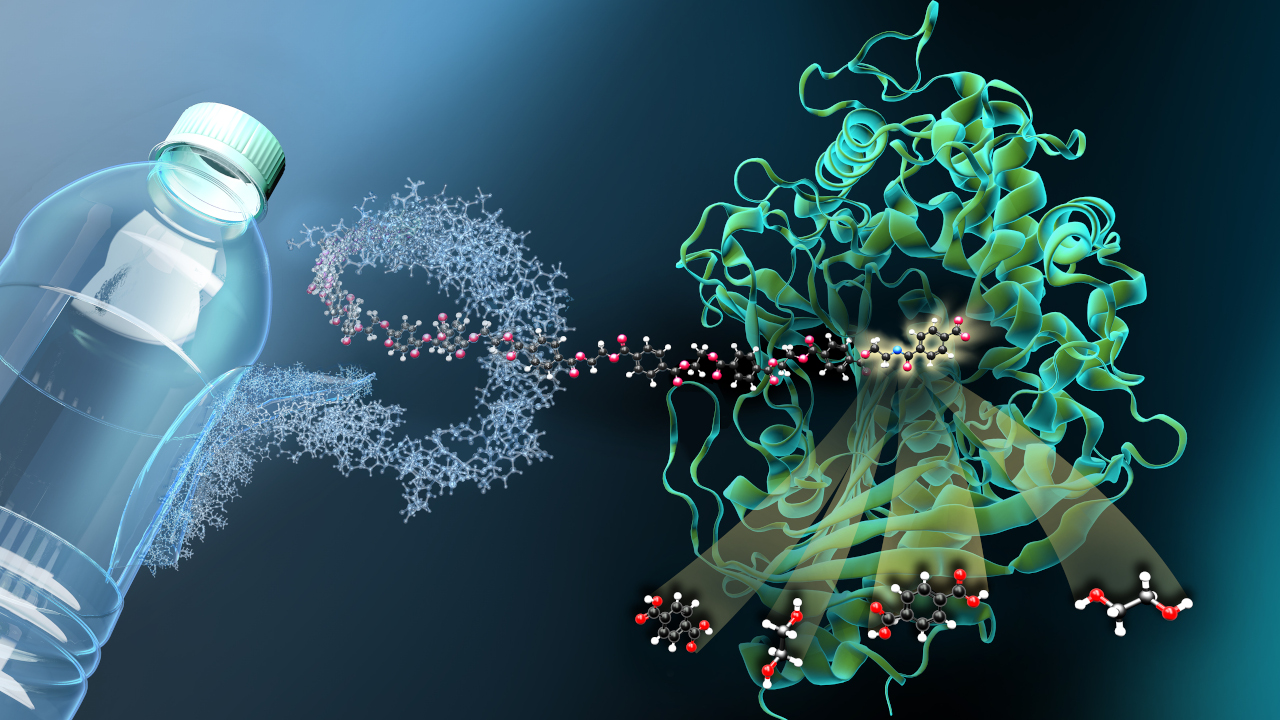

Already the production of plastic consumes vast resources and is petroleum-based. This is why Stute is developing an economically viable process for the production of bioplastic in the research project "Biobased production of the biodegradable bioplastic polybutyric acid (PHB)". According to Stute "Polybutyric acid is a colourless polyester and is regarded as the most promising substitute for petrochemical polymers. So far, the production costs for this bioplastic have been very high, which is why industry is not yet using it on a large scale." Her project is supported by the Staedtler Foundation with €40,000.

Two-tiered process enables efficient PHB production

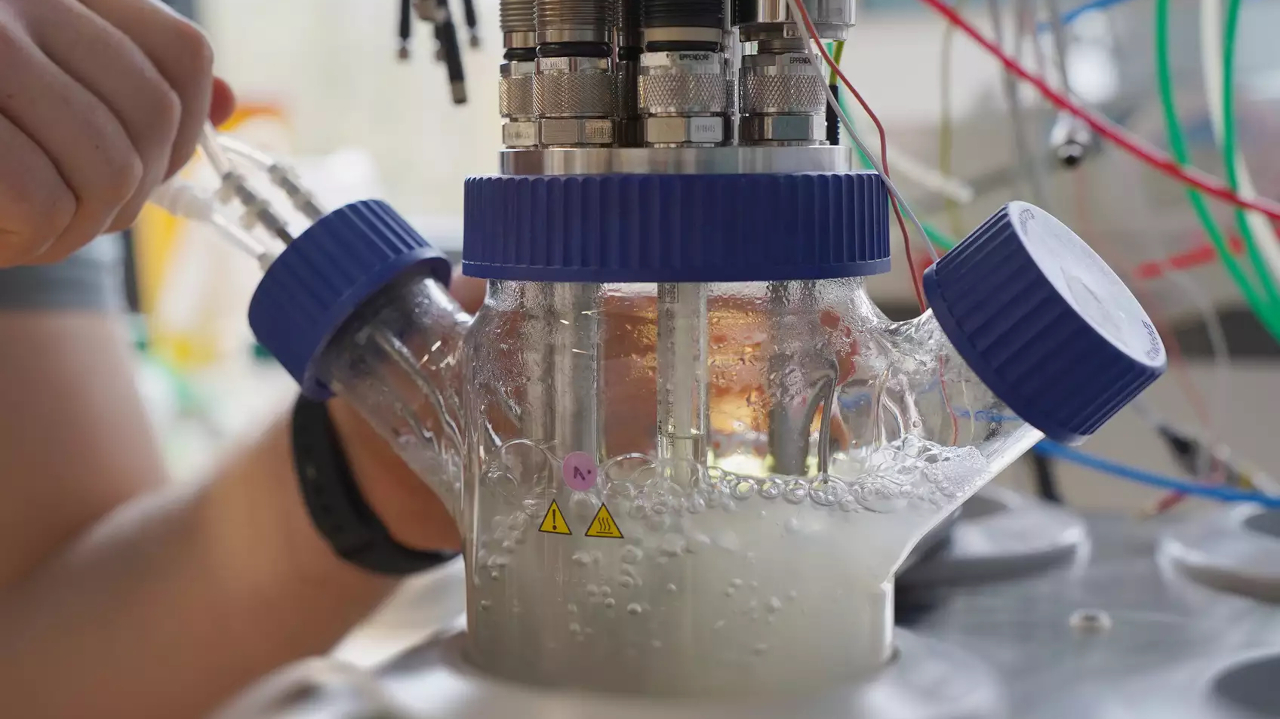

PHB is currently produced using bacteria that take up the biopolymer as a storage material. The problem: Bacteria can only be cultivated and multiplied under conditions that are rich in oxygen and nutrients, whereas PHB is only stored under deficient conditions. Therefore, the new approach of Stute is based on two bioreactors connected in series, whose nutrient concentrations are continuously regulated. In the first stage the growth conditions are optimal, while in the second stage a nutrient deficiency is caused.

Low-cost raw material keeps production costs low

This two-tiered process enables the bacteria to produce large amounts of polybutyric acid. At the outlet of the second bioreactor, Stephanie Stute and her team isolate the PHB from the bacterial cells that have been detached from the culture medium. The bacterium C. necator seems to be particularly suitable for mass production - it stores PHB up to 80% of the dry biomass. The process engineers from Nuremberg use raw glycerine as a raw material, which is available at low cost in large quantities and thereby enables low production costs of the bioplastics.

jmr