Investment in innovative cell culture systems

Innovative cell culture systems that are set to revolutionise production processes in the pharmaceutical and biotech industry – the start-up Green Elephant Biotech is now receiving support from Bürkert Fluid Control Systems for this vision.

The manufacture of pharmaceutical and biotech products is usually associated with high material consumption. For this reason, the Giessen-based start-up Green Elephant Biotech has developed recyclable cell culture vessels. These not only reduce the carbon footprint by up to 90% compared to conventional disposable items, but also improve the growth conditions of the cells. This solution is now being further developed in a strategic partnership with the family-owned company Bürkert Fluid Control Systems.

Single-Use vs. CellScrew

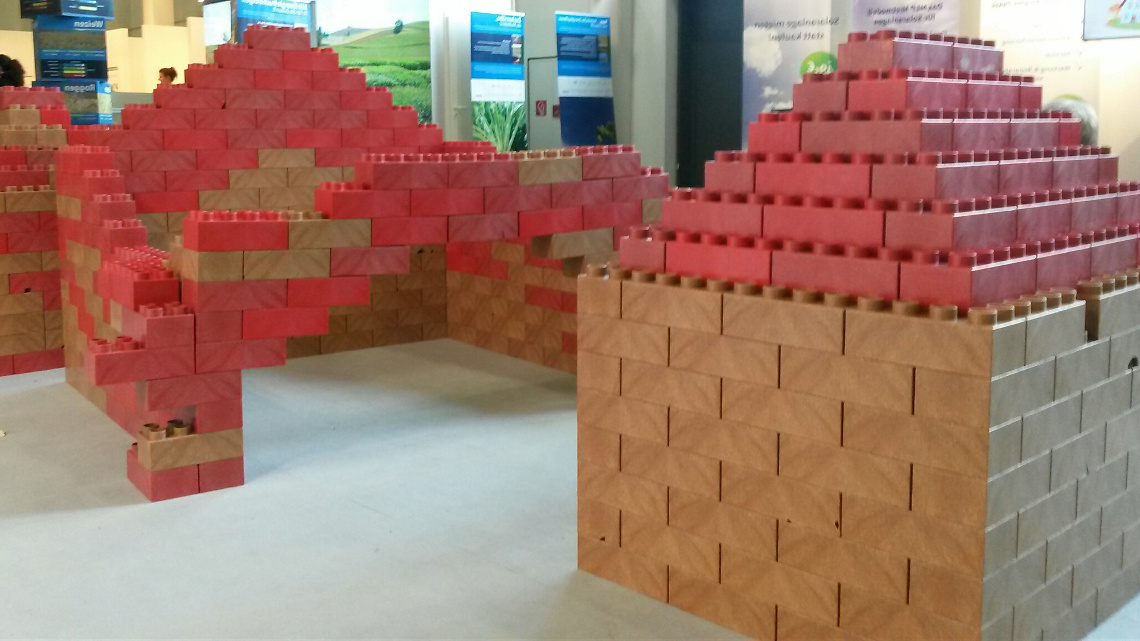

‘Traditional single-use cell culture vessels are significantly larger, are disposed of after the first use and are often incinerated for regulatory reasons - this generates a lot of CO2,’ explains Felix Wollenhaupt, co-founder of Green Elephant Biotech. The new CellScrew cell culture system, on the other hand, requires less raw material and therefore reduces waste. It also consists of polylactic acid (PLA), a bio-based plastic that is obtained from plants and is suitable for 3D printing. ‘This reduces the carbon footprint by around 90% compared to conventional systems,’ Wollenhaupt continues.

More cost-effective production of life-saving therapeutics

In addition to the significant CO2 savings, CellScrew offers further advantages: Compared to conventional cell culture vessels, it provides a larger growth surface for cell cultures with the same volume. This should make manufacturing processes more efficient and flexible overall. ‘Together, we want to develop a process-reliable and more sustainable production platform for the pharmaceutical industry - especially for personalised medicine,’ says Green Elephant Biotech co-founder Joel Eichmann. This could help to produce life-saving therapeutics more cost-effectively.

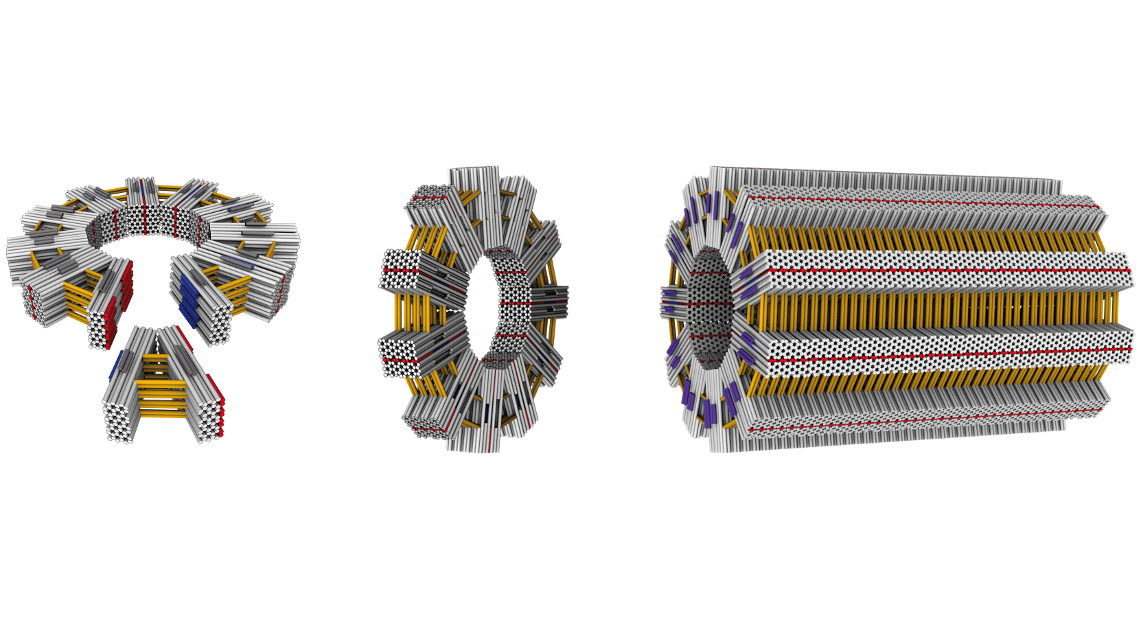

Vision for the future: CellScrew as a fully-fledged bioreactor

The long-term goal of the new partnership is to further develop CellScrew into a fully-fledged bioreactor. Bürkert Fluid Control Systems will contribute essential technical components and its expertise. At the same time, Bürkert will gain access to current biopharmaceutical trends.

lh