BASF: Millions for new fermentation plant

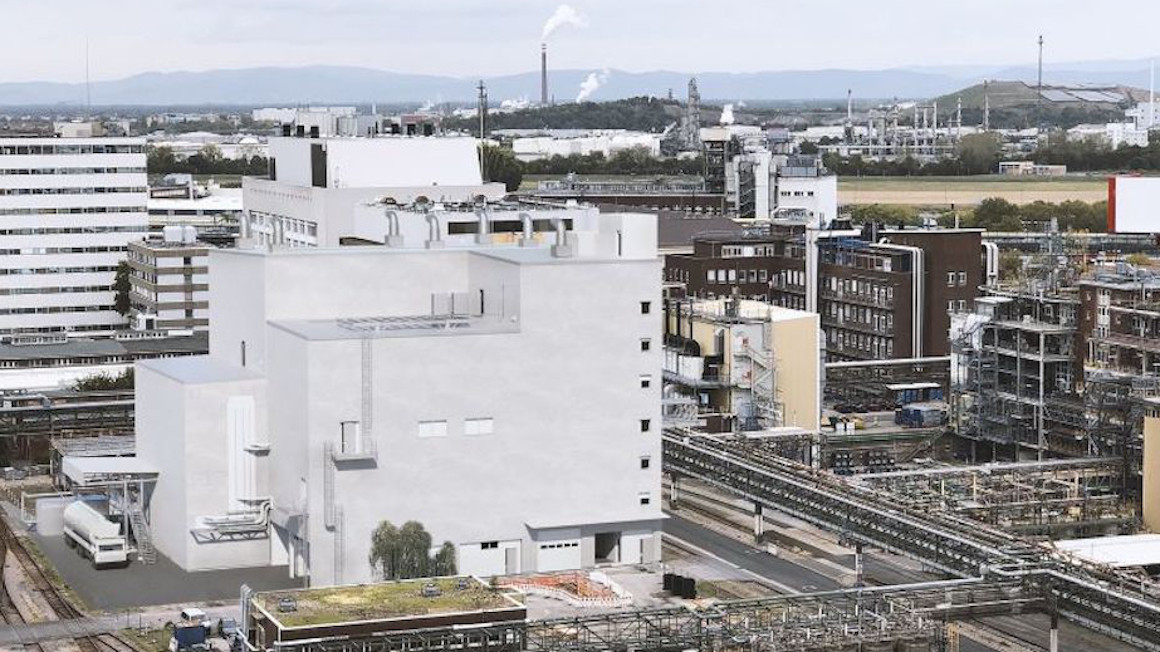

The chemical company BASF SE is investing a high double-digit million amount in a new fermentation plant in Ludwigshafen for the production of sustainable crop protection products.

Bacteria and fungi have long been important tools for the chemical company BASF to make the chemical industry more sustainable. With their help, renewable raw materials such as glucose can be converted into bio-based and environmentally friendly products through fermentation. The new fermentation plant at the BASF site in Ludwigshafen is therefore a further step for the listed company in the planned conversion of its production processes towards sustainability. According to the chemical company, it is investing a "high double-digit million euro amount" in the construction.

Conversion to manufacturing processes based on renewable raw materials

"For production at BASF's Ludwigshafen site, this development is another step in the transition to new, innovative manufacturing processes based on renewable raw materials," says Christian Aucoin, Head of Global Production at BASF Agricultural Solutions. "The site offers excellent conditions for this investment with its good infrastructure, integration into an existing efficient production organisation and proximity to research units such as White Biotechnology."

New plant produces fungus-based insecticide

With the construction of the plant, BASF intends to expand its portfolio of biological and biotechnologically produced crop protection products. According to the company, the plant will manufacture products that can be used as biological fungicides and for biological seed treatment in agriculture. One focus of production is the manufacture of a fungus-based insecticide developed by BASF called Inscalis. The microorganisms used in the new plant include the fungus Penicillium coprobium, which forms a direct precursor of the insecticide.

"We see an increasing demand for biological crop protection products. This investment is an important step towards building an even stronger and more competitive portfolio in this area," says Marko Grozdanovic, Head of Global Strategic Marketing at BASF Agricultural Solutions.

Commissioning planned for 2025

Commissioning of the plant is planned for the second half of 2025. Around 30 jobs will be created there in the areas of production, logistics, engineering and maintenance.

bb