Waste material of the present, raw material of the future

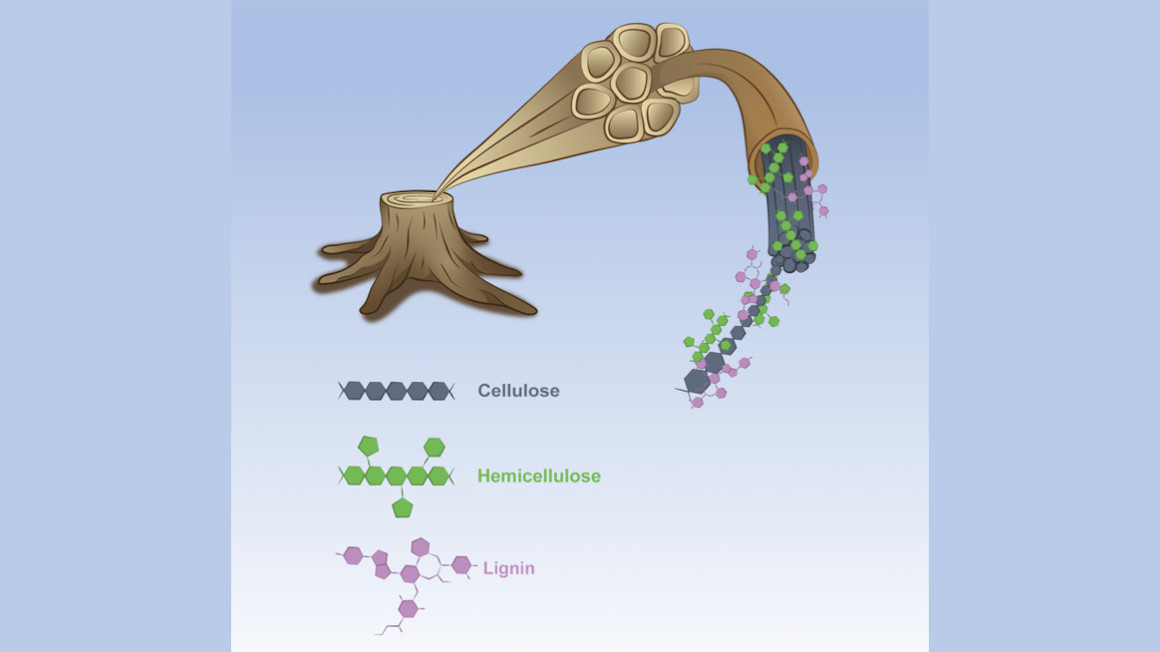

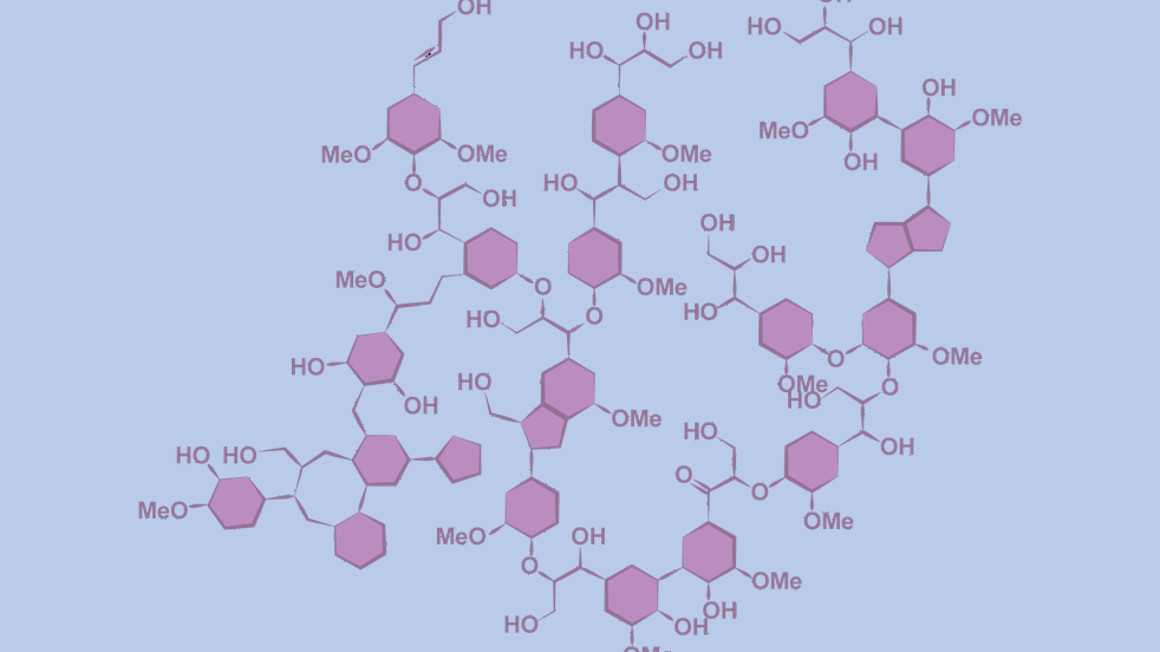

Lignin is one of the most abundant biopolymers in nature and forms the largest renewable source of aromatic building blocks. There is no one lignin; instead, it is a group of complex molecules. In combination with cellulose and hemicellulose, lignin forms wood, or lignified biomass (lignocellulose). This includes not only the wood of trees and shrubs, but also, for example, the stalks of grasses and cereals.

Cellulose and hemicellulose form the structures of plant cell walls, into which lignin is incorporated to provide strength and stability. Lignocellulose has long been produced in large quantities in forestry, agriculture and downstream sectors and is mainly used as a fuel and construction material. With the industrialization of papermaking, lignin was initially produced separately from cellulose and hemicellulose and in larger quantities as a residual material, where it is separated from the other fibers as an interfering component. To date, lignin has mainly been utilized thermally and thus serves as an energy source for the actual production process. Some material uses, such as the chemical synthesis of flavorings, have been pushed back in recent years because problematic waste is produced in the process.

For some time now, more modern processes have been developed to utilize and process lignin materially and sustainably: either as a heterogeneous mixture, as occurs in nature or in paper production, or purified by new processes so that it can also be used for more specialized applications. In this dossier, research approaches and some of the technologies for extraction, processing and utilization are presented as examples.

Page 2 of 5

Cracking molecules to unlock potential: The extraction of lignin

Even in biotechnological approaches in which lignified biomass serves as feedstock, the cellulose and hemicellulose have so far mostly been purified and used for further steps. In most cases, lignin is still treated as a residual material and thermally utilized.

In lignocellulosic biorefineries, lignified biomass is separated into its three basic components: cellulose, hemicellulose and lignin. Lignin is very stable and not just a single molecule, but a biochemical mixture. Purification involves some effort. One possibility is therefore to process and use lignin mixtures directly after separation in their raw form (some examples are given in the next section).

However, innovative approaches in bioeconomy research are aimed at the material use of this complex molecule. Many of the applications rely on lignin that is as pure as possible to be efficient and cost-effective. For example, lignin produced as a residue in pulp mills contains sulfur compounds that are problematic for many downstream processing steps. Various research approaches are therefore working on making such pure lignin available. At Fraunhofer CBP, for example, the lignin is obtained in a particularly pure form using a special process. In this process, the lignin is separated from cellulose and hemicellulose with the aid of increased pressure, increased temperature, water and ethanol.

The Brandenburg-based start-up LXP Teltow uses a relatively gentle process to dissolve lignin from cellulose and hemicellulose, thereby achieving sulfur-free lignin with 90% purity. Researchers in the European SElectiveLi project, on the other hand, have set themselves the goal of purifying lignin into aldehydes using an electrochemical process. To this end, surpluses from the generation of regenerative energy are to be used to make the process economical and sustainable. In another EU project called Sweetwoods, nine European companies have joined forces to build a biorefinery in Estonia that will also produce high-purity lignin from lignified biomass.

So there are already many approaches on the way to making pure lignin available to the bioeconomy for biobased products.

Page 3 of 5

An almost endless range of products: applications for lignin

Lignin, as obtained after a classical chemical separation of cellulose and hemicellulose, cannot be melted or molded, has a brownish color, and is not odorless. Despite these drawbacks, a number of biobased applications of this biological residue are being considered, including:

- Additives, adhesives, wood tar and binders

- Admixture in car tires, where the lignin replaces petroleum-based carbon black (corresponding plans exist at UPM)

- Soil improvement either in the form of the straw residues from harvested grain in fields or also by spreading residual lignin. Both have positive effects and the latter approach additionally releases less CO2 than, for example, spread straw. This is because the rotting of cellulose and hemicellulose releases more CO2 than that of lignin.

- The Austrian company Lignovations, a spin-off of the Vienna University of Technology, has developed a process for the development of colloidal lignin that can be used for products with beneficial properties such as UV protection or anti-inflammation.

- The company LignoPure prepares lignin for applications in the cosmetics industry.

Innovative further processing can turn raw lignin into a moldable material. For example, it can be combined with bioplastics under electron irradiation to form a composite and then shaped by extrusion. In this way, materials can be produced from lignin. Another method is used by the Tecnaro company (see also this interview with Jürgen Pfizer), in which lignin is mixed with other biological polymers and resins. This allows numerous products made from petroleum to be replaced, including conventional plastics, for example.

Other processes are based on processed, pure lignin. Here, the complex biopolymer is used as a platform for a variety of new, biobased chemicals, which in turn represent platform chemicals for a wide range of specific applications.

For example, vanillin can be obtained from lignin by means of electrochemical synthesis (if energy from renewable sources is used in this process, this is also referred to as "green chemistry"). Currently, over 90% of the vanillin used worldwide is produced synthetically, i.e. not from vanilla beans. Most of it is now petrochemical, made from fossil source materials. For several decades now, vanillin has also been synthesized chemically from lignin, which is a residual material in paper production. However, the conventional process produces toxic waste, which is why most production has been scaled back and replaced by petroleum-based production. Newer processes, which make use of electrolysis, for example, are said to allow unproblematic extraction from lignin. However, unlike lignin produced by biotechnological means, lignin obtained in this way cannot yet be described as a "natural" flavoring.

Lignin can also be used for energy storage, in "batteries made of wood". For this purpose, so-called quinones are obtained from the lignin, which can then serve as electrolytes in batteries.

Carbon fibers are also still mainly produced from fossil raw materials today. But instead of being made from petroleum-based base chemicals, lignin with its high carbon content can also serve as an excellent starting material and thus replace petroleum.

Page 4 of 5

Upgrading lignin with biotechnology: focus on three innovative projects

Fungi and bacteria as lignin architects

Microorganisms are predestined for the degradation of the very stable molecule lignin, especially fungi and bacteria that decompose wood in nature. Their enzymes are specialized in splitting the complex structure and can therefore replace high-energy conventional processes in biotechnological applications.

The enzymes (known as ligninolytic enzymes) are researched and then produced in larger quantities using genetic methods. Other specialized enzymes, in turn, can biochemically modify the building blocks of lignin and thus lay the foundation for the development of new products. Susanne Zibek's group at the Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB, among others, conducts research on this.

New products from lignin thanks to biotechnology

One possible modification of the lignin building blocks is fermentation to cis,cis-muconic acid using microbial cell factories. The molecule is a so-called platform chemical and provides access to important industrial chemicals that are needed in large quantities in the pharmaceutical industry, for the production of plastics and agrochemicals. Until now, these have all been produced in energy-intensive processes from fossil raw materials.

With the help of various microorganisms such as Corynebacterium glutamicum or Pseudomonas putida, Christoph Wittmann's research group efficiently converts lignin-based aromatics into cis,cis-muconic acid. The bacterial strains, which have been optimized by means of metabolic engineering, can process complex mixtures of aromatic compounds as well as industrial hydrolysates and pyrolysates of lignin. From the purified cis,cis-muconic acid, the team at Saarland University is now using chemistry to synthesize biobased adipic acid and biobased nylon.

The research group is also already able to produce other relevant substances from lignin, for example the important plastic PET, which was previously produced purely by petrochemical means, and PHA, a degradable biopolymer. Through the innovative coupling of chemical and biological steps, the complete value chain from lignin to finished industrial chemicals can be demonstrated in this way for the first time.

Eco-efficiency analyses assess these new processes as environmentally friendly and economically attractive. Further information can be found on the working group's website (in German).

Development of optimized enzyme teams

The processes in which lignin is broken down and converted with the help of microorganisms or their enzymes must be further improved in order to be able to obtain marketable products from it. Prof. Volker Sieber and his research group at the Technical University of Munich are not only developing special enzymes that can break down lignin better and synthesize new products from the building blocks, but are also working on optimizing processes to make better use of lignocellulose.

One example is so-called convergent conversion, in which precisely fitting teams of enzymes are connected together and in series to effectively convert starting materials of heterogeneous composition into the desired platform chemicals.

Page 5 of 5

Bottom line

The use of lignin illustrates one of the great strengths of the bioeconomy: energy-intensive processes based on fossil raw materials can be replaced by more sustainable, biological processes. The complex biomolecule lignin, which is difficult to access biochemically, is first broken down into its components with the help of customized microorganisms or their specialized enzymes. These are then used to synthesize a variety of new compounds and products. Through innovations in both the utilization of the residual lignin and the development of products, potentially sustainable alternatives to existing processes and products are being developed on the basis of bioeconomy research.