Around the world, there is a huge demand for cost-effective and efficient energy storage on a large scale. The fluctuating supply of wind and solar power requires storage solutions that can absorb surplus energy and release it when needed. Sustainable e-methane is a promising approach. It can replace fossil natural gas in the existing gas grid and at the same time serve as a storable energy source or be stored directly on site and used later as fuel, heat or electricity.

Development of a microbial electrolysis cell

As part of the PtG-MEC project, Electrochaea GmbH, based in Planegg near Munich, is working on the development of a microbial electrolysis cell (MEC) for the so-called power-to-gas (PtG) process. This project with the full title “PtG-MEC – Development of a high-density microbial power-to-gas electrolysis cell” is being funded by the German Federal Ministry of Education and Research (BMBF) with around 400,000 euros and will run from July 2022 to March 2025. The aim is to find a cost-efficient solution for energy storage.

The power-to-gas process can be used to convert surplus electricity - for example from wind or solar energy – into e-methane. This bio-electrochemical process takes place in two steps in an electrolysis cell, which consists of two electrodes separated by a membrane in an aqueous solution.

In the first step of electrolysis, the current flowing through these electrodes is used to split water (H₂O) into its components hydrogen (H₂) and oxygen (O₂). In the second step, the hydrogen produced in this way is then mixed with carbon dioxide (CO₂) and both gases are converted into methane (CH₄) by the biocatalyst. “This e-methane is therefore climate-neutral,” explains Jose Rodrigo, Director Product Development & Innovation. “The carbon dioxide that is released during methane consumption was previously extracted from the atmosphere. This type of CO₂ recycling ensures that the e-methane does not contribute any additional emissions to global warming.”

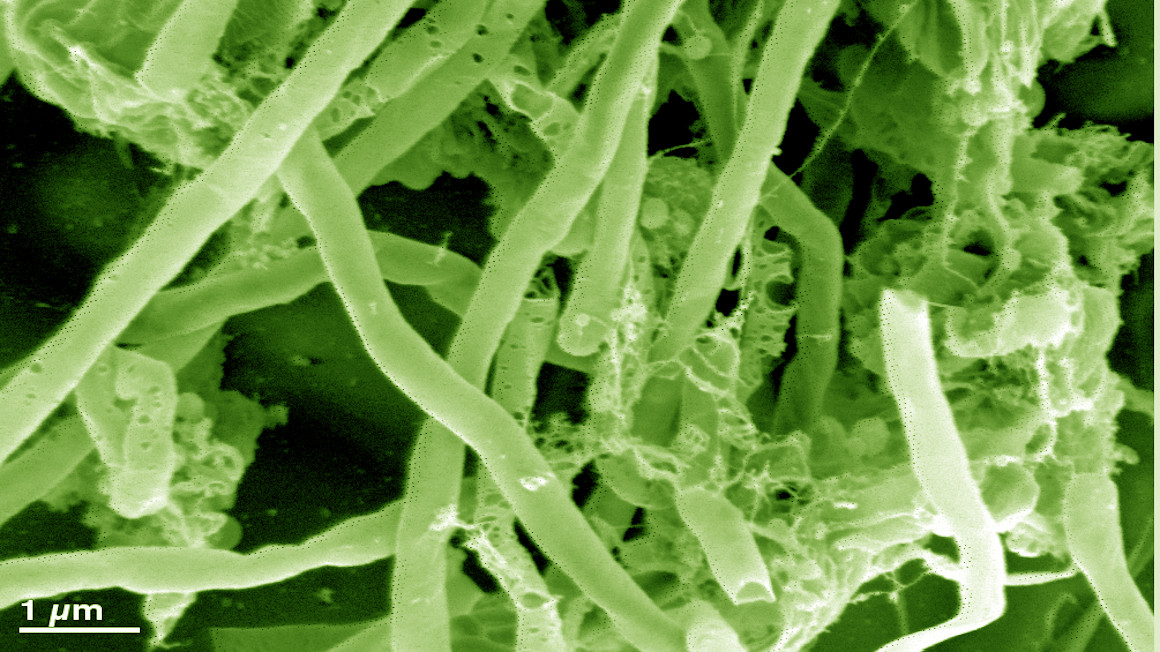

What makes Electrochaea unique is that it uses an environmentally friendly biocatalyst instead of chemical catalysts for methanation. It is based on archaea – microorganisms that have existed for billions of years and can convert CO₂ and hydrogen into methane. “Our biocatalyst is particularly flexible and robust, ideal for industrial applications and fluctuating, renewable electricity,” says Rodrigo. Compared to conventional processes producing hydrogen as an end product, methane is easier to compress and store.

Archaea as a biocatalyst

Electrochaea uses a selectively developed, non-genetically modified and particularly efficient strain of archaea that converts almost all of the CO₂ into e-methane and requires very little energy for its own growth. Coupled with the high productivity of the biocatalyst, even small bioreactors can produce large quantities of e-methane - a decisive advantage in the microbial electrolysis cell with its limited volume. Chemical methanation processes often require extreme conditions, such as high temperatures or pure CO₂. Electrochaea's biocatalyst, on the other hand, operates at mild temperatures and pressures and can utilize mixed waste gases.

A key challenge was scaling up the technology. With a small distance between the membrane and electrodes, Electrochaea was able to increase the energy density of the cell and reduce material requirements. “This was a very particular challenge for which there was no out-of-the-box solution. We had to have many materials and components specially produced and extensively tested,” notes Rodrigo.

Plans for a transportable container system

As microbial growth and electrolysis require completely different conditions in terms of pH value and temperature, the optimum process parameters first had to be found. Finally, the geometric design of the cell and the shape of the electrodes could also be adapted to further increase productivity. “Part of the carbon dioxide emitted in Germany comes from many fairly small producers, such as biogas plants and breweries,” says Rodrigo. Electrochaea is therefore planning to offer the technology as a transportable container system to efficiently address smaller CO₂ sources. According to Rodrigo, Electrochaea has already received many inquiries for such a container solution.

The system is to be further optimized and scaled for industrial applications by 2025. Once the project is completed, the construction of a pilot plant in the kilowatt range is planned. “Our PtG-MEC technology offers a solution to the storage problem of renewable energies and contributes to the sustainable transformation of the energy supply through CO₂ recycling,” emphasizes Rodrigo. With this development, Electrochaea is making an important contribution to a bio-based and sustainable economy.

Author: Christian Kähler