Biotechnology is no longer a new field, yet innovative processes are constantly emerging. Many of them could reach market maturity, but there is no industrial implementation routine in place yet. Among these are bioelectrochemical processes. The core of microbial bioelectrochemistry is the interaction of microorganisms with electrodes. Some bacteria can breathe with electrodes: Electrons generated during the production of a recyclable material are then not transferred to oxygen by these organisms during respiration, but are passed directly to an electrode. This means that the production of such materials can be coupled with the provision of electrical energy as a by-product. But can such a process be implemented and scaled industrially?

Continuous bioprocess for acetoin

The research project "Conti-Bio-Elect", which is supported by the Federal Ministry of Education and Research within the framework of the "Microbial Biofabrics" funding program, aims to provide the answer. On the academic side, the Engler-Bunte Institute and the Institute for Applied Biosciences at the Karlsruhe Institute of Technology (KIT) are participating and together will receive around 800,000 euros. On the business side, Eisenhuth GmbH und Co. KG from Osterode is on board. The common goal is to develop a continuously operated bioreactor in which the proteobacterium Shewanella oneidensis produces acetoin from glucose and grows on an electrode that absorbs the released electrons instead of oxygen. Acetoin has been mainly chemically synthesized to produce flavors and is one of the top 30 platform chemicals.

"Anaerobic bacteria produce less biomass and have potentially higher product yields," says KIT project manager Harald Horn, citing an important argument for the continuous process envisaged. Unlike batch processes, the reactor is not completely stopped, cleaned, and restarted every one or two days. Rather, the bacteria live inside the reactor for several weeks or even months fixed to surfaces, the substrate flowing in at one end and the product being removed at the other - non-stop. The continuity makes the process economically very attractive, but leads to problems if the microorganisms multiply too quickly and excess biomass has to be removed in addition to the product.

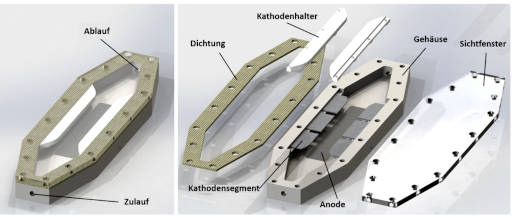

This is what the assembled flow cell (left) and as an exploded view (right) look like, as it is used in the Conti-Bio-Elect research project.

A flow-through biofilter as a reactor model

"So far, there are no reactor systems adapted for our purpose," explains Horn. "Although we ourselves have experience with such biofilm reactors, the growth surfaces in the reactor have not previously consisted of electrodes. One challenge will therefore be to identify the suitable anode material on which the microorganism will successfully adhere and grow. The anode structure should offer the largest possible surface area in order to accommodate as many bacteria as possible. As a reactor variant, an upflowing biofilter with a bed of growth carriers in the form of granules was chosen. Last but not least, this granulate, of which the anode is to consist, must be so dense that the electrons can still flow and provide the optimal electrical potential for the microorganisms. To achieve this, the quantity, density and porosity of the granulate must be optimized. The research team is currently working on a polymer interspersed with graphite. If all this is successful, high turnover rates may be possible.

Initially, a small flow cell is used to test which conditions and materials offer the best results. In the course of the three-year project period until the end of January 2023, a process is then to be created in a 10 or 20-liter reactor, which in principle can be scaled up to industrial dimensions. This could then consist of several independent layers of granulate to adjust the appropriate potential. Despite the pandemic, the reactor development subproject is so far on schedule.

One gram per liter and hour as target

The team of microbiologists in the project is also moving quickly, because although S. oneidensis is electroactive by nature, it must be genetically optimized in this respect to achieve economically attractive metabolic rates. This is to be achieved by means of the genomediting tool CRISPR/Cas. The research group can rely on ten years of experience with the proteobacterium. The tests in the flow cell will be used to verify success: "You can see how well the organism grows on the anode," Horn explains, "and we can recognize how productive it is by the flow of current" - more electrons mean more productivity.

If the bacterium grows in the bioreactor over a longer period of time and under high load, the research team hopes to achieve a very specific number: If S. oneidensis produces at least one gram of acetoin per liter per hour, "then the process is economically attractive and we have reached our goal," says Horn with confidence.

Author: Björn Lohmann