Textile coatings made from lignin

In the EU project BioFibreLoop, researchers are developing textile patterns and coatings made from renewable and recyclable materials - also for outdoor clothing.

The textile industry is facing the challenge of becoming more sustainable and environmentally friendly. At the same time, the demand for functional textiles is growing, but their production often involves the use of harmful chemicals. These not only harm the environment and health, but also make recycling more difficult.

In order to reduce the high carbon emissions of textile production, innovative solutions are needed to replace these chemicals, save water and use recyclable, bio-based materials. This is precisely where a major EU joint project comes in.

EU project for innovative functional textiles

The EU project BioFibreLoop aims to develop recyclable outdoor and work clothing made from renewable, bio-based materials. Renewable raw materials such as lignin, cellulose and polylactide (PLA) are used. A lignin coating is intended to protect the textiles, while an additional sealant ensures water and oil-repellent properties.

The project started in June 2024 and will run for 3.5 years. It is being funded with 6.5 million euros as part of Horizon Europe. The project involves 13 partners from 9 countries and is coordinated by the German Institute of Textile and Fibre Research (DITF) in Denkendorf.

Testing lignin fibres and high-tech coatings

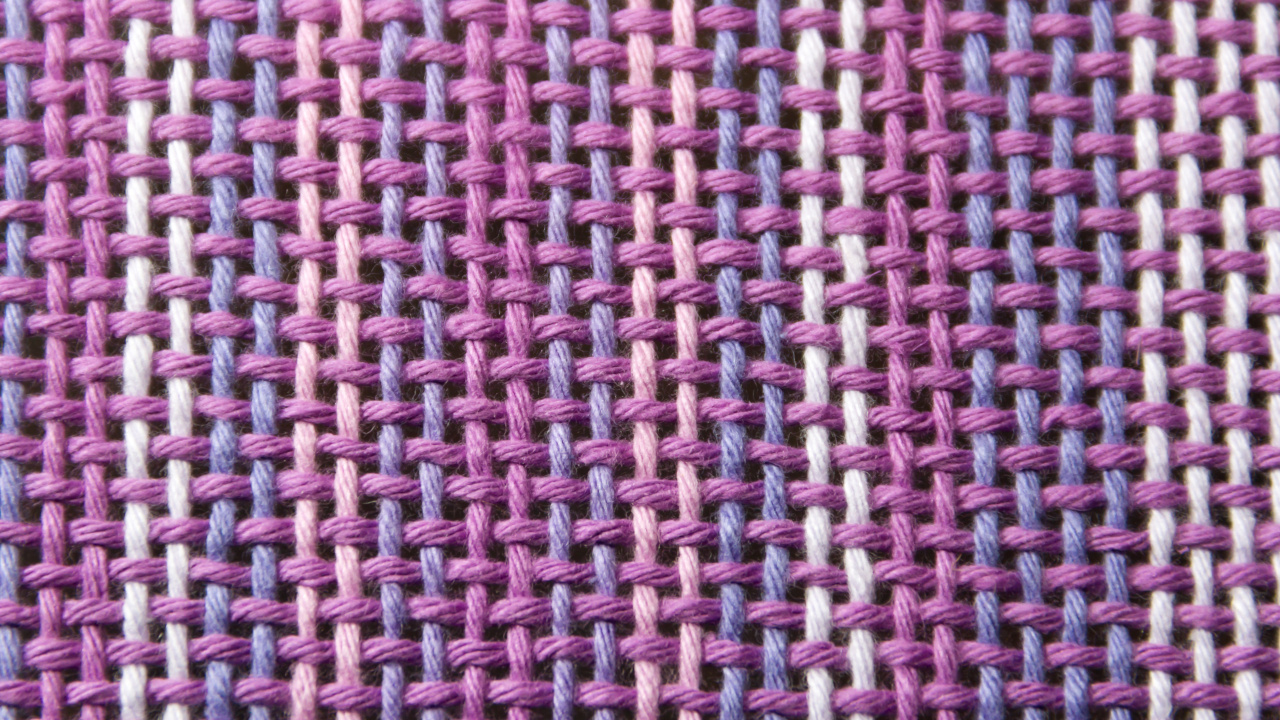

BioFibreLoop has already achieved its first successes: In the first few months, the project participants have succeeded in spinning fibres and sample fabrics from a mixture of lignin and cellulose. Additionally, thin films have been produced from these materials, which are to be applied to the fabrics in the next stage of the lamination process. At the same time, other textures and fibre variants are being tested with PLA.

To protect the surfaces from water and oil, the researchers are taking inspiration from the micro- and nanostructures of certain plants and fish. The knowledge gained will be used to develop suitable functional properties. The plan is to transfer such biomimetic structures to the lignin coating using a novel, laser-based embossing process. Intensive research into how this can be optimally realised is still being conducted at the DITF and elsewhere.

ck