Control grain weevil with plasma

With the help of an innovative plasma technology, researchers have paved the way to protect grain from pests and thus make it last longer.

Grain weevils eat into grain husks, lay their eggs in the grain and can thus destroy entire harvests. The light-shy weevils are mainly found in grain and storage warehouses. When there is a massive infestation of the crop, "heat nests" develop. This increases humidity and thus the risk of fungal spores attacking the grain. Experts estimate that pest infestation of stored grain causes millions of dollars in damage worldwide. So far, there are hardly any ways to control the pests efficiently - certainly not without chemical insecticides. Researchers at Neubrandenburg University of Applied Sciences and the Leibniz Institute for Plasma Science and Technology (INP) in Greifswald now have an environmentally friendly solution ready.

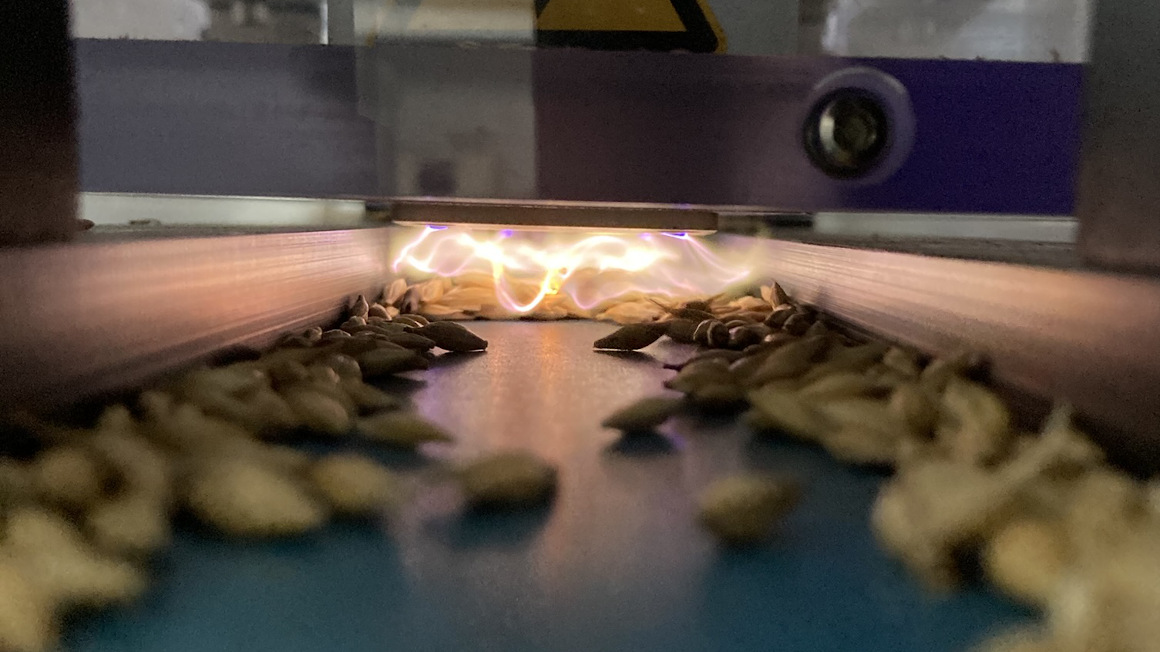

Plasma air flows around the grains on the conveyor belt

As part of the Physics for Food & Feed project, a process has been developed over the past two years that uses plasma to render grain weevils harmless in harvested crops. In collaboration with the project partner automation & software Günther Tausch from Neubrandenburg, a conveyor belt was specially equipped with four plasma sources and a three-meter-high silo was set up for this purpose. Here, plasma air flows around the grain on the conveyor belt, rendering the pests harmless.

Grain weevil in cereals rendered 99% harmless

In laboratory tests, the cold atmospheric pressure plasma was able to render 99% of the grain weevils in the grain harmless. According to the researchers, the special feature of the so-called plasma silo is the combination of a gas-tight bulk silo with the innovative plasma technology for pest control. The prototype also offers researchers the opportunity to record the climatic conditions and gas composition inside and to treat and take samples of the bulk material during storage.

Field test for plasma silo

From now on, the process will be tested in practice. "In the coming weeks and months, we will conduct experiments using the conveyor belt and check whether the results from the laboratory can be confirmed," says project manager Sebastian Glaß. Among other things, the tests will determine which throughput of grains and which conveyor speed are appropriate to achieve the greatest benefit. With the help of plasma technology, the use of pesticides could be reduced and the grain harvest optimized.

"Physics for Food & Feed" is part of the project "Physics for Food - Eine Region denkt um!" (A region rethinks!) and has been funded by the German Federal Ministry of Education and Research since 2018 as part of the initiative "WIR! - Wandel durch Innovation in der Region" (Change through Innovation in the Region). The focus of the large-scale project is the development of new physical technologies for agriculture and food processing.

bb