CO₂ conversion using formic acid

A research team at the Max Planck Institute for Terrestrial Microbiology has developed an artificial enzyme that efficiently converts formate, a salt of formic acid, into formaldehyde. This enables the conversion of CO₂ into valuable raw materials.

A carbon-neutral bioeconomy requires processes that efficiently bind carbon dioxide and convert it into usable products. Formic acid – or rather its salt, formate – is considered promising in this regard, as it can be produced from CO₂ using renewable energy. It is also easy to transport, non-toxic and versatile. Research in this area focuses, among other things, on microorganisms that are supplied with formic acid obtained from CO₂ and use it to produce basic chemicals or fuels. A research team at the Max Planck Institute for Terrestrial Microbiology has now developed an enzyme that efficiently converts formate into formaldehyde.

Missing component found

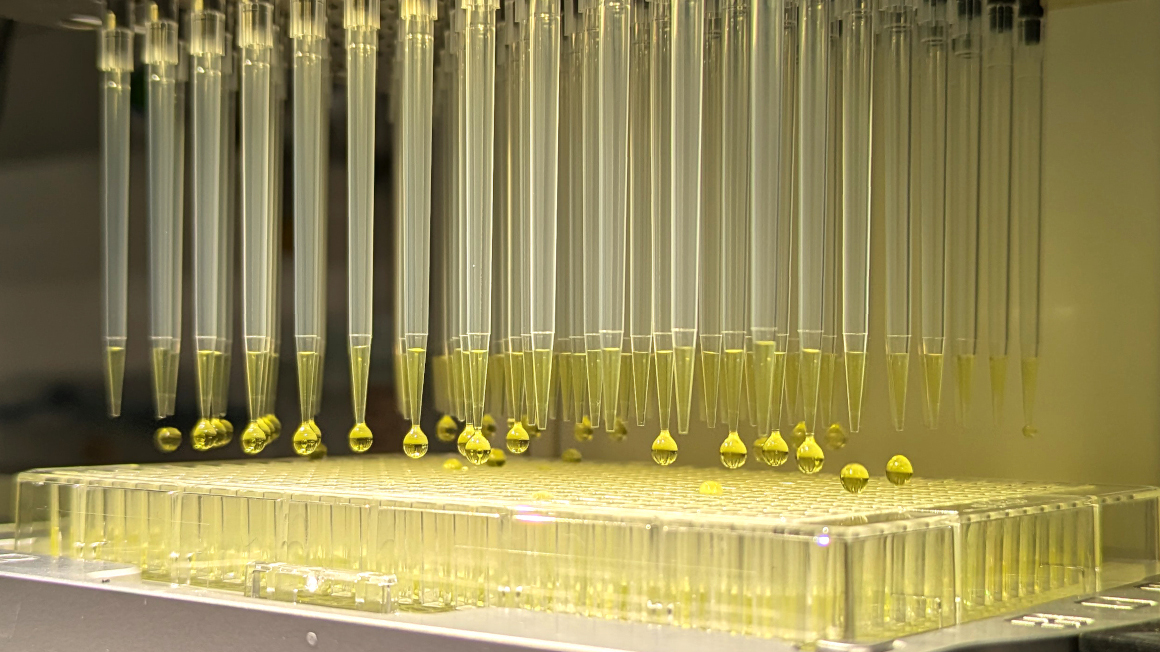

The research group led by Maren Nattermann has made a decisive breakthrough with the development of a tailor-made formate reductase enzyme. The enzyme, known as FAR, was optimised from a carboxylic acid reductase from the bacterium Mycobacteroides abscessus through targeted mutagenesis and high-throughput screening for small molecules such as formate. ‘With FAR, we now have a single, robust enzyme that reliably reduces formate to formaldehyde – exactly where many biotechnological pathways begin,’ explains Nattermann. ‘This provides us with a missing component for future bioconversions based directly on CO₂-derived raw materials.’

Industrial processes and molecules

‘The most important thing is that our enzyme itself tolerates high formate concentrations – because under these conditions, previous systems failed almost completely,’ says Philipp Wichmann, first author of the study. It is precisely this stability that makes FAR attractive for industrial processes in which formate is produced electrochemically in very high concentrations.

With the FAR enzyme, CO₂-based formate can be converted into basic chemicals, bioplastics or fuels in living cells as well as in cell-free or electrobiochemical systems. The researchers are already planning to combine FAR with other synthetic metabolic pathways, for example to produce energy-rich molecules.

lh