Adhesives modeled after beetle feet

Bionic scientists at the University of Kiel have designed silicone material surfaces based on the model of a leaf beetle, thus significantly increasing its adhesion to other materials.

They hang upside down from the ceiling, adhere effortlessly to steep trees and even polished glass won't make them slip: geckos. Millions of small hairs on the toes give the inconspicuous reptile adhesive forces like a magnet. For scientists, such natural wonders have always been a fascinating field of research and an incentive to transfer these abilities to technical applications and materials. Following the example of nature, researchers in Kiel already developed an extremely adhesive tape that works according to the "gecko principle " and can be removed without leaving residue.

Bionics meets physics

Now, researchers at the Christian-Albrechts-Universität zu Kiel are presenting a novel plastic structure whose surface adheres to glass like beetles on a leaf. As the scientists reported in the scientific journals "Advanced Materials" and "ACS Applied Materials & Interfaces", they adapted the mushroom-head-like surface structure of the feet of certain male leaf beetles (chrysomelidae) and subsequently treated these surfaces with plasma. The studies were carried out within the framework of the Collaborative Research Centre 677 "Function by Switching".

Reversible adhesion without adhesive

The focus was on silicone elastomers. This elastic plastic is preferred in industry for seals, insulation or corrosion protection. The material is extremely flexible, can be used several times and is affordable and easy to manufacture. Due to the small surface, however, the material hardly sticks. The goal of the Kiel researchers: The new plastic should adhere in such a way that the bond is reversible at any time and does not require adhesives. This is where nature came to their aid.

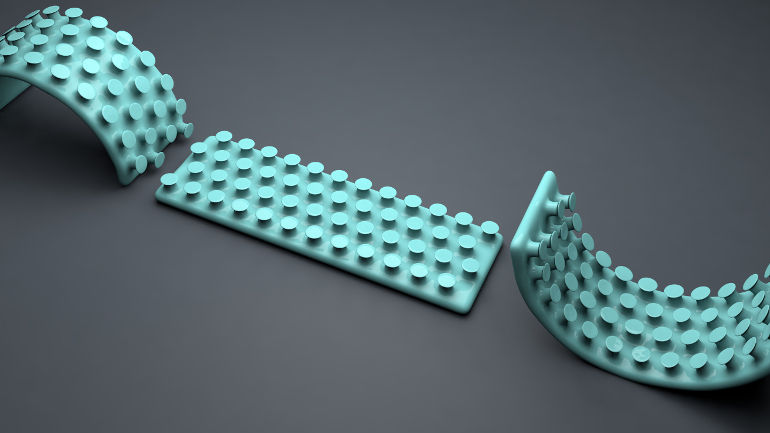

The adhesive effect of the silicone material, whose surface has a mushroom-head-like structure, changes with different curvature. Curved inwards (concave), the adhesive effect is greatest (right).

In a first step, Stanislav N. Gorb and Emre Kizilkan compared silicone elastomers with three different surfaces: one unstructured, one with columnar elements and one with the mushroom-head-like structure of the leaf beetle. They then adhered a glass ball to the material, pulled it off again and tested how the adhesion changed. The researchers were thus able to prove that the adhesion property of the microstructured silicone material is also influenced by its degree of curvature. "We were thus able to show that silicone elastomers with a mushroom-head structure have a twice greater range of adhesive strengths in the concave curved state. With this surface geometry, we can best vary the adhesion and have the greatest control," explains doctoral student Emre Kizilkan, first author of the study.

Strong adhesion in the smallest of spaces

In a second study, it was found that the adhesive effect can be significantly improved if the mushroom-head-like surface is treated with plasma. The researchers varied the duration and pressure of the plasma treatment and were able to achieve up to 91% higher adhesion at the end of the mushroom-head-like structured surface. For unstructured surfaces, the adhesion was 30% higher. "We were particularly surprised by this result because the structured contact surface is only half the size of the unstructured surface, but after plasma treatment the adhesion was increased three times as much," explains Kizilkan.

Potential for use in miniature robots

Images taken with a high-speed camera showed that the plasma-treated microstructure of the surface remained completely bonded to the glass substrate for 50.6 seconds. Untreated, the material detached from the glass carrier after 33 seconds because the contact surface shrank. "In a very small space, we therefore have a strong adhesion that we can vary extensively," summarizes Kizilkan. The researchers are convinced that the results are of particular interest for applications in microelectronics and miniature robots.