New impulses for electrobiotechnology

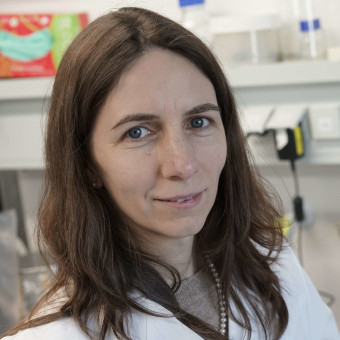

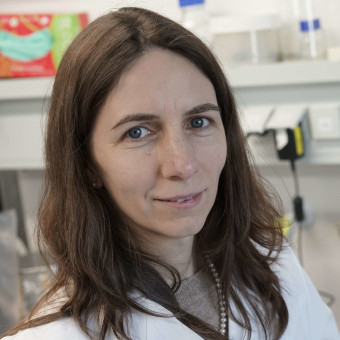

Miriam RosenbaumProfession:

Graduate biochemist

Position:

Professor for Synthetic Biotechnology at the Friedrich-Schiller-University Jena and Head of the Department of Biotechnology at Leibniz HKI Jena.

Profession:

Graduate biochemist

Position:

Professor for Synthetic Biotechnology at the Friedrich-Schiller-University Jena and Head of the Department of Biotechnology at Leibniz HKI Jena.

Biochemist Miriam Rosenbaum is a true pioneer in the field of electrobiotechnology. In the following interview she explains how she intends to replace oxygen in biotech processes.

For some time, electrobiotechnology research teams have been investigating how electric power from microbial metabolic processes can be utilized. It is thought possible to use this electricity for the biotechnological production of oxygen-sensitive enzymes or biochemicals. The key is to remove the oxygen from the bacterial metabolism. In the "e-MICROBe" project, biochemist Miriam Agler-Rosenbaum from the University of Jena is researching how this can be achieved. She receives support from the European Research Council’s "ERC Consolidator Grant", which is worth 2 million euros.

Mrs Rosenbaum, you are considered a pioneer of electrobiotechnology. What is so special about your field?

I always thought it was fascinating that bacteria can interact with electrodes. At first, the idea was to use this interaction to generate electricity from microbial processes, like from wastewater with microbial fuel cells. But now we are also working on using this interaction for biotechnology, for example for the production of enzymes or biochemicals. This opens up opportunities to intervene and realign the energy balance of bacteria in a completely new way. The issue is very interdisciplinary - it combines the biology and biochemistry of cells, but also electrochemistry and process engineering - which makes it very exciting!

In your "e-MICROBe" project, you want to develop biotechnological processes in which bacteria do not require oxygen. What is the problem with oxygen?

For most existing processes, oxygen is not a problem: it enables a simple and very successful energy production in the bacteria. However, there are processes where the necessary oxygen input becomes a technical issue, for example when products tend to foam a lot or when the biomass becomes highly viscous. Moreover, there are many metabolites or enzymes in nature that are quickly inactivated by oxygen. The majority of bacteria in the environment live without oxygen - anaerobically. I would say that we are currently neglecting a large molecular potential of this anaerobic world because we do not have scalable technological processes for oxygen-sensitive products. In common anaerobic fermentation processes, the cells usually receive significantly less energy and mainly products of primary metabolism can be formed.

How do you intend to get rid of the electrons from the microorganisms' energy metabolism instead?

We want to derive the electrons via an electrode, but not by "wiring" them, so not by binding them directly to the electrode via redox enzymes – as some colleagues plan and do – but rather "wirelessly", via soluble redox mediators that serve as taxis for the electrons. The big challenge, however, will be to combine this electron transport to the outside within the cell with an energy, in this case ATP, production.

You are investigating two systems, the "all-in-one" solution and co-cultivation. What does this mean and what are the advantages and disadvantages?

This new biotechnological process requires two different microbiological syntheses: the production of the redox mediators as electron transfer taxis and the production of our target product. Since the synthesis of the redox mediators is relying on complex synthesis pathways with several enzymes, this already represents a burden for the cell. We will therefore test whether there is still enough capacity in the cell to effectively form the target product or whether a division of work with two cell populations would be more efficient: one makes the redox mediator, the other uses it for electrode breathing and product formation. Of course, it is then necessary to investigate how these populations influence each other and to develop strategies for the stable cultivation of the two.

Why can' t you just optimize anaerobic microorganisms whose metabolism naturally does not require oxygen?

There are two types of anaerobic metabolism: fermentation and anaerobic respiration. We use anaerobic fermentation metabolism extensively for the production of metabolites of the central metabolism of these organisms, such as ethanol and methane. Since these organisms can only produce energy through substrate metabolism - not through respiration - they boost their metabolism and leave the excess metabolites as important biotech products. Since these organisms have a low supply of ATP, other synthesis tasks - for example of enzymes - are rather not possible with this energy metabolism. Anaerobic respiration, in particular with nitrate as electron acceptor, would provide considerably more energy, but would bring the big disadvantage that adapted amounts of nitrate would have to be added to the substrate, which leaves ammonium as a product. And ammonium is the real problem when it is present in excessive amounts. It alters the pH value considerably, it can become toxic for bacteria and it is a critical parameter for wastewater treatment. Although this last point only becomes relevant for very large production plants, it shows that nitrate respiration is not easily scalable. In contrast, electrode respiration would not lead to the formation of toxic or problematic by-products.

So ultimately, your new approach should enable new biotechnological products?

Yes, as already mentioned, through the new anaerobic electrode respiration we hope to gain access to oxygen-sensitive metabolites and enzymes on a technical scale. So far, this is only possible in small, non-scalable cultivations or in natural producers. If electrode respiration is established in an already optimized biotech strain, larger quantities of these target products could be produced.

Interview: Björn Lohmann