Trial run for algae farms on high seas

As part of an international research project, researchers in Braunschweig are investigating how seaweed can be successfully cultivated in offshore facilities in order to relieve the pressure on coastal areas.

Many fish species such as salmon and trout are now bred in aquaculture facilities to meet the increasing demand. As a rule, these fish farms are located near the coast, where breeding is impaired by shipping, tourism or buildings. An international research team involving researchers from the Technical University of Braunschweig now wants to move aquaculture to the open sea.

Tapping into the agricultural potential of the open sea

The project, which was launched in 2021 and will run until 2026, focuses on the development of a new type of seaweed farm, which is to be installed as a prototype off the coast of New Zealand. ‘This could be used to tap into the agricultural potential of the open sea,’ says Nils Goseberg, Head of the Leichtweiß Institute of Hydraulic Engineering at TU Braunschweig.

However, the construction of algae farms on the high seas is associated with significantly greater challenges than comparable farms in coastal areas. Not only are they located in deeper waters, but they are also exposed to higher waves and stronger currents.

Offshore conditions in the wave pool

One of the tasks of the Braunschweig researchers was to precisely determine the forces acting on the offshore installation. In order to analyse the behaviour of seaweed and farm structure under real conditions, several series of tests were carried out at the Leichtweiß Institute.

For example, a two-metre-long wave channel was used to investigate how the forces and movements of the seaweed change under different wave conditions and how the plastic ropes on which the seaweed grows influence each other. For this purpose, substitute bodies were built, mimicking the shape of the seaweed so that the deformations of the algae are realistically modelled. Specialised sensor systems were then used to record the flow field around the algae structure, while so-called load cells were used to determine the forces acting specifically on the plants. These findings were in turn fed into computer models in order to check and further optimise the load determination for the entire offshore plant.

Seaweed farm recreated on a scale of 1:20

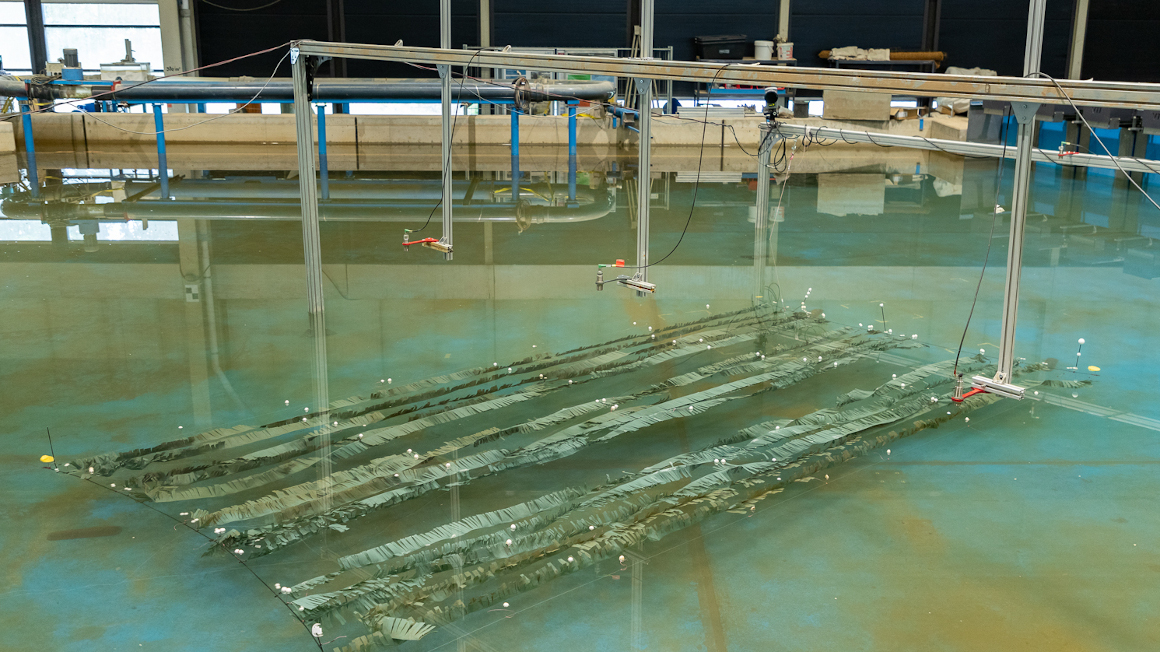

For the next series of tests, a 1:20 scale seaweed farm was recreated in the wave pool. The aim here was to determine whether the system would work under real offshore conditions. Different materials were tested for the head lines, which connect the cultivation lines to each other and thus serve as connection points between the anchor and the farm, as well as different types of anchoring systems to ensure optimal conditions for seaweed growth. ‘The tension and stability of the lines are particularly important to ensure consistent growth conditions in terms of light and nutrients,’ explains project team member Henrik Neufeldt from the Leichtweiß Institute.

Deformations and movements analysed

By combining force sensors, wave levels, speed sensors and motion tracking cameras, the team was able to record and analyse the deformations and movements of the system in detail.

The project, titled ‘Ngā Punga o te Moana’, is led by the Cawthron Institute in New Zealand and funded by the New Zealand government with around 11 million New Zealand dollars. The aim of the researchers is to make offshore aquaculture sustainable and efficient in order to meet the growing demand for marine resources - not just for food production. At the same time, the development of new technologies should help to protect the marine ecosystem.

bb