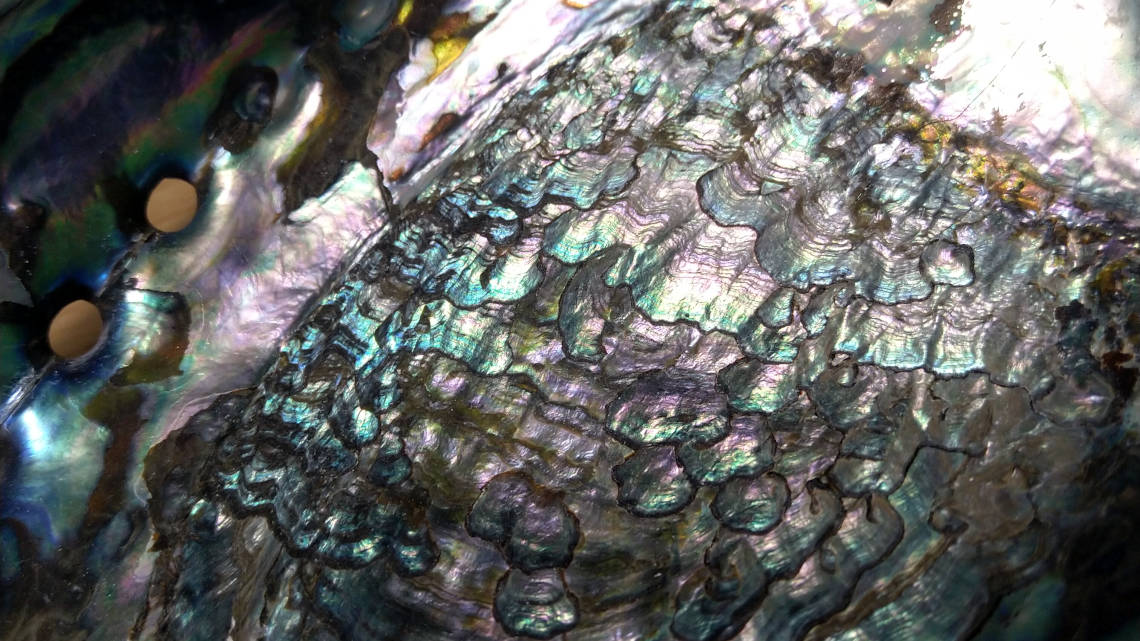

As strong as mother-of-pearl

Researchers have shed light on the structure of nacre in mussels, paving the way for break-resistant ceramic materials.

The mother-of-pearl inside a shell is not only beautiful to look at, it has also fascinated materials researchers for decades because of its exceptional toughness. It is considered one of the most resilient materials in the world. “Nacre is the prototypical supermaterial,” the researchers, including scientists from the Friedrich Alexander University Erlangen-Nuremberg (FAU), write. Their team has succeeded in explaining the materials toughness, they report in the journal "Nature Communication".

More than the sum of the parts

Mother-of-pearl consists of microscopically small aragonite particles, so much was known. It is a mineral composed of lime. In nacre, the particles are structured by organic compounds. But neither the aragonite nor the organic component can explain the toughness of the mother-of-pearl. The material is more than the sum of its parts.

Reversible structural change under pressure

Using an electron microscope, the researchers observed what happens in mother-of-pearl when they exert pressure on the material. "The grain structure on the nanoscale is key to this hierarchical and hybrid organization. It arises from tiny particles which assemble on the nanoscale," explains Stephan Wolf, materials researcher at FAU. This is possible because the mussel is able to assemble the smallest lime particles into platelets. These consist of layers of aragonite and organic material. Under pressure, however, the organic material moves to the side and the plates of the mineral layers interlock and thus stabilise each other. When the pressure decreases, the system returns to its original state.

Potential for synthetic materials

"It’s incredible that a mollusk, which is not the most intelligent creature, is fabricating such complex structures across so many scales," explains Robert Hovden, head of the study at the University of Michigan. What is particularly surprising is that even after numerous repetitions, the nacre shows practically no loss in elasticity and strength. So far, materials researchers have not been able to produce this property in any artificial material. The FAU team would therefore like to analyze the processes in nacre even more closely in order to be able to synthetically imitate these " fantastic properties " one day. The scientists see potential applications, for example, in dental or bone implants. “Nature is handing us these highly optimized structures with millions of years of evolution behind them,” said Hovden. “We could never run enough computer simulations to come up with these—they’re just there for us to discover.”

bl/um