Solar modules based on wood and sugar cane

Fraunhofer researchers have developed a solar module in which individual components are made from renewable raw materials and can be recycled at the end of their service life.

Whether on roofs, balconies or in the field. Photovoltaic systems are an important cornerstone in driving forward the energy transition in Germany. In order to accelerate the expansion, the German government passed a corresponding law this year in the form of Solar Package I. But even solar modules do not last forever. The current service life is 20 to 25 years. A concrete recycling concept for these systems, which contain valuable materials, does not yet exist. Researchers from the Fraunhofer Center for Silicon Photovoltaics CSP in Halle (Saale) have been working with industrial partners to research materials that make solar modules more sustainable and can be returned to the cycle.

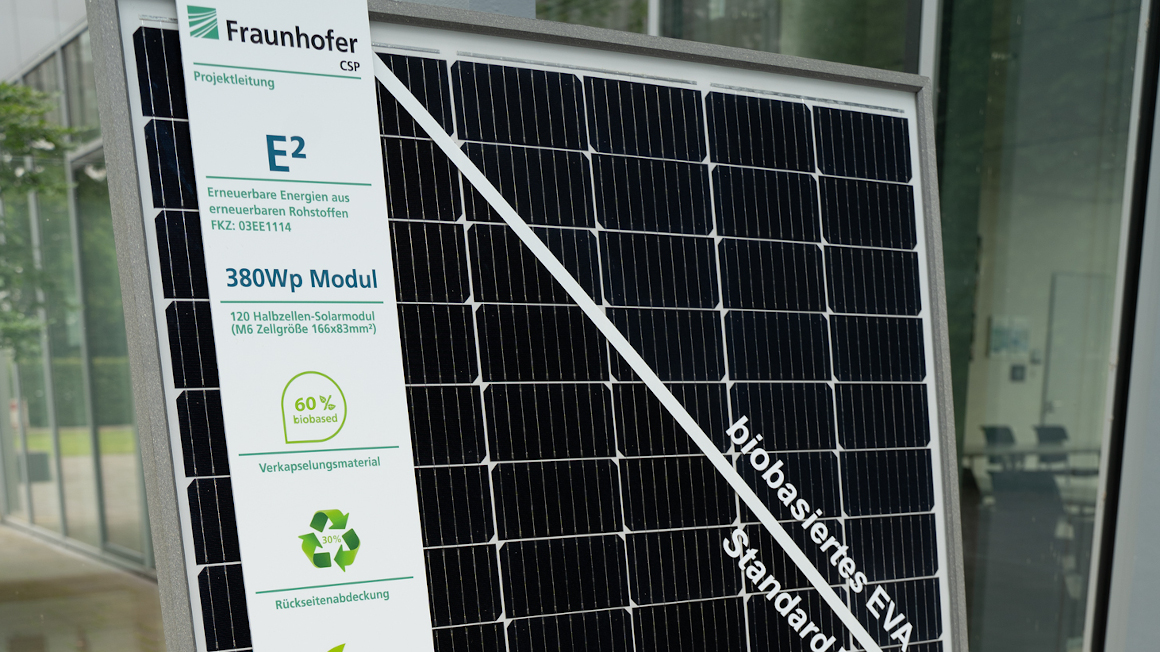

Conventional solar modules consist of glass, polymers, metals and silicon-based solar cells - materials whose production and extraction pollute the environment. As part of the project “E2 - E-Quadrat. Renewable energies from renewable raw materials”, a solar module has now been created that is partly made from renewable raw materials. According to the researchers, the components of the “bio-module prototype” that are not directly required for light-to-electricity conversion are made from biodegradable materials, recyclable materials or renewable raw materials.

Frame and foil made from bio-based raw materials

The frame of the module is made to a high degree from wood, which can be recycled at the end of its service life and reused to manufacture new solar modules. The module's cell connections, which are normally connected with lead-containing solders, have here been replaced with an electrically conductive adhesive that contains silver particles and serves as a connector between the wires and the cells. In addition, 30% recycled polyethylene terephthalate (PET) was used for the back cover, which consists of a film. This ethylene vinyl acetate (EVA) film, which is used as a transparent plastic layer in the production of solar modules and serves as encapsulation material for the cells, is also not made from fossil raw materials, but from 60% bio-based ethylene obtained from sugar cane.

“The project addressed all life phases of a PV module: From production using materials made from renewable raw materials, through the actual operating phase, to material recycling and return to the recycling loop at the end of its service life,” says project manager Ringo Köpge, research associate in the ‘PV Modules, Components and Manufacturing’ group at Fraunhofer CSP.

Biopolymers also suitable for photovoltaics

Ageing, heat, humidity and temperature cycling tests have shown that every single new component in the bio-module prototype meets current module standards. With this first more sustainable solar module, the researchers have also provided proof that biopolymers are suitable for use in photovoltaics and can also be used for other more complex outdoor applications in the future. The use of bio-based raw materials and their reuse would also significantly improve the carbon footprint for the production of photovoltaic systems. The project was funded by the Federal Ministry of Economics and Climate Protection (BMWK).

bb