New composite material made from plant-based carbon fibres and biochar

As an alternative to reinforced concrete, researchers at the German Institute of Textile and Fibre Research have developed a combined building material made of natural stone, carbon fibres and biochar that has a particularly good carbon footprint.

According to Deutsche Umwelthilfe, the construction sector is responsible for 40 % of total raw material consumption and 12 % of greenhouse gas emissions in Germany. The joint project DACCUS-Pre pursued a promising approach to reducing greenhouse gas emissions in the construction sector. In this project, researchers led by the German Institute of Textile and Fibre Research (DITF) together with the company TechnoCarbon Technologies have developed a building material that not only binds carbon in the long term, but also absorbs more CO2 than is released during production.

House wall made of sustainable building material also environmentally friendly

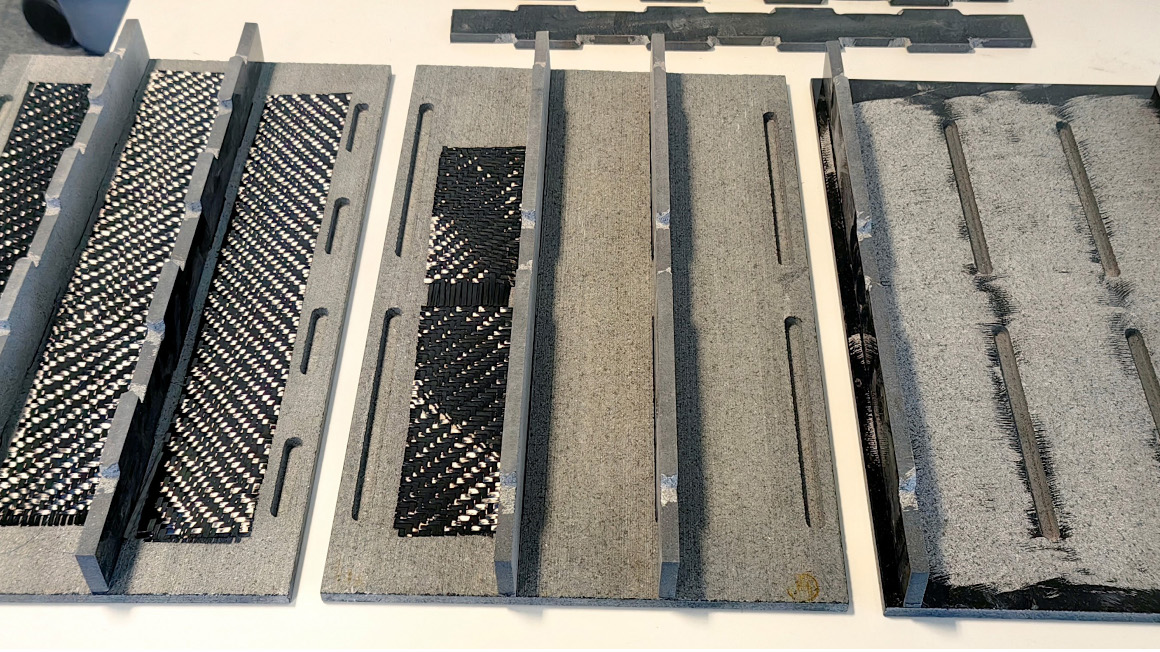

The focus was on the development of a composite material consisting of natural stone, plant-based carbon fibres and biochar. The first demonstrator, a house wall element, has already been produced and shows how climate-friendly the new building material is. Compared to a house wall made of reinforced concrete, the carbon footprint of a house wall made of the new building material would be much more positive. The researchers' calculation showed a difference of 157 CO2 equivalents per square metre of house wall.

Each individual component - natural stone, carbon fibre and biochar - therefore contributes to the negative CO₂ balance of the new wall element. For example, large quantities of stone dust are produced when the two natural stone slabs that form the exposed walls are cut to size. This is very reactive due to its large specific surface area and permanently binds large quantities of climate-damaging carbon dioxide through silicate weathering alone. The natural stone used was a rock from India that is suitable for particularly high loads.

Better energy and CO2 balance

The carbon fibres used in turn consist of plant-based biomass and serve as cover layers for the stone slabs. Lignin-based carbon fibres are used, which have been technically optimised at the DITF. According to the researchers, not only are the costs of producing these bio-based carbon fibres low, but the carbon yields are also high.

"Although carbon fibres are more energy-intensive to produce than steel, as used in reinforced concrete, only a small amount is required for use in the building material," the researchers write. The bottom line is that the energy and CO2 balance is in fact negative due to the use of biomass and solar heat in the production of bio-based carbon fibres, which makes CO2-negative construction of buildings possible, they say.

Insulation material made from biochar as an additional source of CO2 storage

The biochar is in turn used as a filling material between the rock slabs, which also serves as an insulating material and, according to the researchers, also represents a "permanent CO2 storage source".

The project was funded by the Federal Ministry of Education and Research from June 2022 to December 2023 as part of the CDRterra funding programme.

bb