Load-bearing beam made from Chinese reed

Researchers at the University of Siegen have succeeded in producing a beam construction made of Miscanthus grass that is more resilient than conventional beams made of solid wood.

Miscanthus is a popular ornamental grass in the garden. However, the perennial and fast-growing plant is also becoming increasingly popular as a raw material - for the production of cellulose for the paper industry or sugar for bioplastics production, for example. The construction industry has also discovered the potential of miscanthus and sees it as an alternative to wood as a raw material. Researchers at the University of Siegen and their partners have now succeeded in producing a beam from the so-called giant Chinese reed that can compete with its solid wood counterpart in terms of strength.

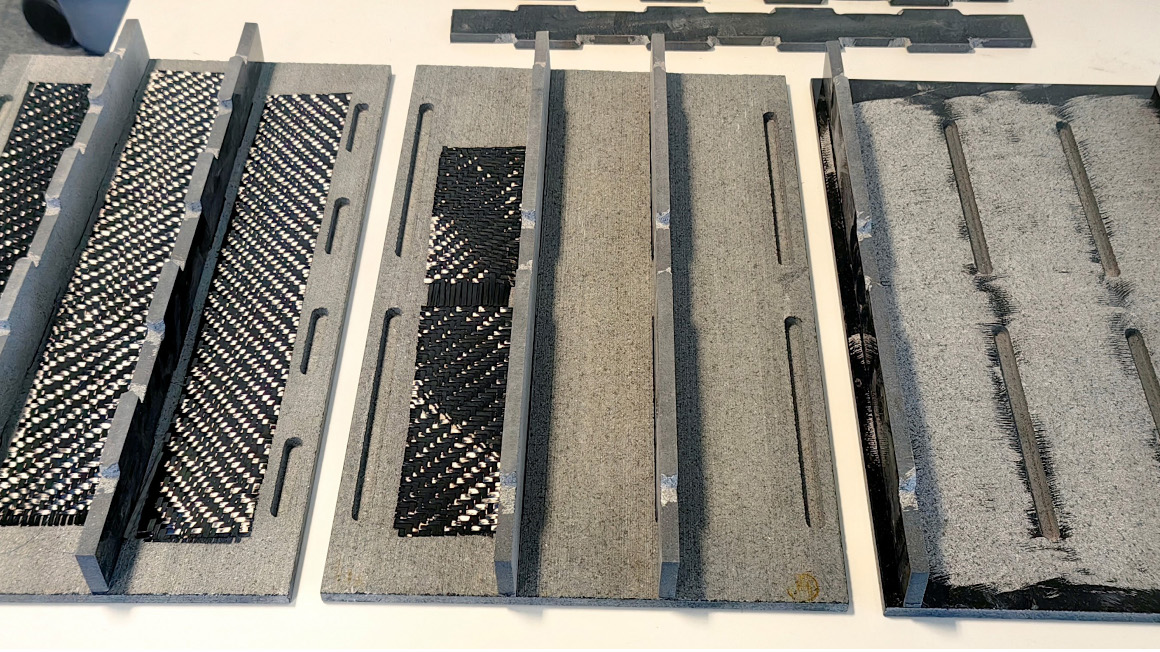

Beam construction made from Chinese reed

The fast-growing grass is already being used as an insulating material. In order to produce a beam from the plant material that meets the high demands for beam construction, the team had to overcome a number of hurdles. “Initially, the main challenge was to join the reed leaves, which have an extremely smooth surface, together,” reports Mathias Wirths from the University of Siegen. With the help of a special machine called “Miscanthus-Biber” (engl. "miscanthus beaver") developed by students, the reed leaves were roughened, glued and finally pressed together to form a 1.10-metre-long beam.

Higher load-bearing capacity than solid wood beams

Initially, the researchers used bone glue as an adhesive. The aim is to produce this component from biological material as well. Although good results were achieved with bone glue and even the load tests in the laboratory were “better than those of solid structural timber” according to the researchers, epoxy resin was ultimately used as the adhesive. The reason: bone glue is not waterproof and therefore unsuitable for use in construction.

The search for bio-glue continues

For the researchers, the search for a suitable bio-glue for the beam construction made from miscanthus continues. In addition, the Siegen researchers are working with RWTH Aachen University and Alanus University to develop connecting elements for the reed beams and thus further promote the renewable raw material as a building material.

Miscanthus has several advantages over the popular building material wood: Once planted in a field, the plant grows for decades and offers a high yield per unit area. The plant, which can grow up to three meters tall, is robust and can be used both as biomass for energy production and as a raw material for new bio-based products. The grass is also quite undemanding and can therefore thrive on marginal land that is of little interest for agriculture.

bb