How bio-based products are transforming the economy

The "Biofabrik" conference presented biobased products and bioeconomic production processes from biotechnology to biorefinery.

The transformation to a biobased economy is in full swing. Start-ups, but also established large corporations, are increasingly producing biobased products using new, often biotechnological production processes. The economic development agency of the German state of Hesse therefore organized the online conference "Biofabrik" on May 25 and 26, 2021, at which experts from business and science presented current developments.

From Lignocellulose to Power-to-X

The first day was dedicated to biorefineries. Kurt Wagemann from the Dechema association gave an introductory overview of the state of the art. He said that biorefineries that utilize sugar, starch, vegetable oils or lignocellulose are already in commercial use. Pilot plants exist for biorefineries based on fermentable sugars and lignin from lignocellulose, grass and synthesis gas. Biorefineries whose raw materials are algal lipids or biogas are more likely to be on a laboratory scale. Attractive here are plants that manufacture several products and make optimum use of the raw materials. However, this has a practical difficulty, as the respective markets, and thus demand and price, develop differently. Regarding the microorganisms and enzymes used in biorefineries, Wagemann said, "We would have even more productive and robust organisms." The expert also presented in more detail the "Volatile" project, which is looking at the use of the volatile fraction in biorefineries, and the "Copernicus" project, which will investigate plants using CO2 and electricity as feedstocks. "Power-to-X projects will be of great importance in the future," Wagemann predicted. That is why he is not talking about decarbonization, but defossilization.

4% of biomass for chemical products

Michael Duetsch of UPM Biochemical also emphasized that in the future, fossil carbon sources will be replaced not only by biomass, but also by CO2 and carbon reuse. Projections for 2050 show that only 20% of carbon demand will be met by biomass. CO2 would account for 25%, and recycling for the rest. This would mean that the chemical industry's demand for biomass would increase from one percent of the available amount today to three to four percent in 2050, but would remain marginal and thus sustainable. Finally, Duetsch presented the plans for UPM's biorefinery being built in Leuna, which will produce industrial sugar, functional fillers, ethylene glycol and propylene glycol from wood and sawmill waste. The fillers in particular are not only more sustainable, but also functionally superior to the established petrochemical alternatives, not least due to their lower weight with the same stability.

Perennial grasses and wood residues as raw material

Asli Hanci of Biowert Industrie presented a fledgling biorefinery that uses perennial grasses as feedstock. Grass is a fast-growing raw material, available almost everywhere in the world, and can be harvested four times a year - although only two of the harvests are of the required quality. In addition, the cellulose is comparatively easy to extract and largely free of lignin. Three products are made from it: thermal insulation material, granules for plastics production and fertilizer. What is then left of the grass is used to generate heat and electricity. Cellulose-based plastics are not only energy-efficient and fully recyclable, but also have a much smaller environmental footprint than petrochemical alternatives, especially in terms of impact on freshwater and saltwater ecosystems, he said.

Peet Pitk from Graanul Biotech explained what can be produced from wood-based cellulose and hemicellulose. The company's raw lignin already has a purity level of 88%, is odorless and has particle sizes of less than 20 micrometers, he said. After acid treatment, the company even achieves a purity of 95%. The biorefinery mainly produces C5 and C6 sugars, which are further processed into isobutene, for example. In the "Sweetwoods" project, the lignin is also used to produce biocomposites and foams.

Biotechnology is changing many industries

A second focus of the conference was on biotechnology and its processes. Stefan Buchholz of Evonik, for example, used a number of biotechnological group products to explain how they were changing the market and why biotechnology would continue to change it. These included amino acids that add value to feed and thus reduce the overall need for feed, probiotics that keep poultry healthier and thus curb the need for antibiotics, and oil from microalgae that avoids having to feed three kilos of fish for every kilo of salmon produced. Other examples included lipid nanovesicles for the delivery of mRNA active ingredients in medicine, special culture media for medical cell cultures, ceramides for skin care, biosurfactants and, in the future, systems for artificial photosynthesis. "Biotechnology is a key tool for developing sustainable products and helping to close the gap to CO2-neutral production," Buchholz summed up.

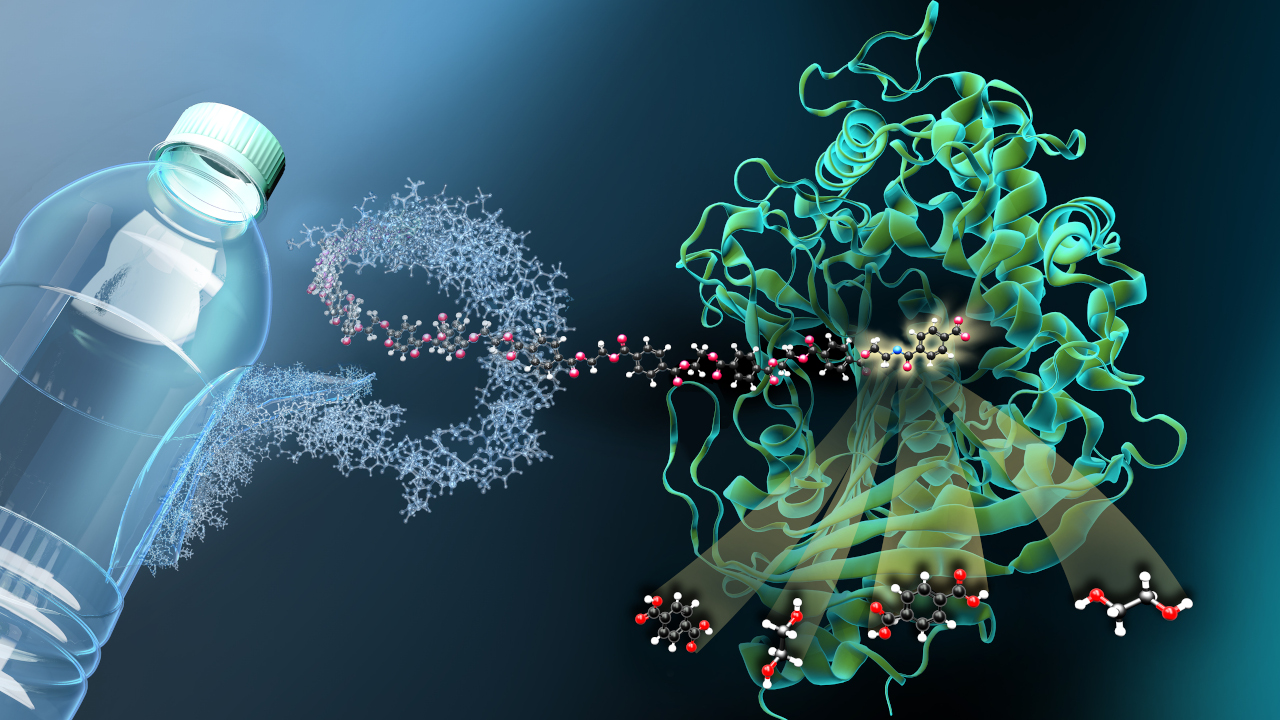

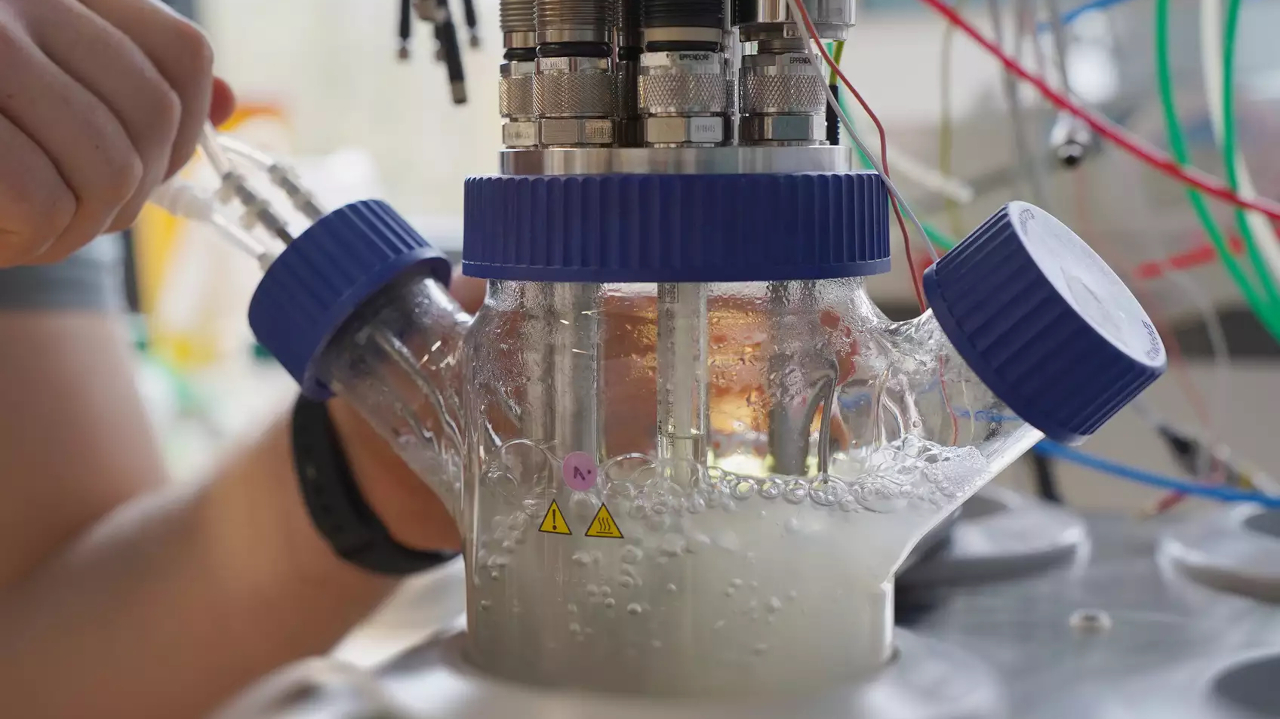

Other examples included flavorings produced from plant side streams and tailor-made lignin among other things for cosmetics. Process technology came to the fore not only in microbial electrosynthesis, which can be used to produce basic chemicals, but also in the topic of enzymes, the custom production of which can once again significantly increase the efficiency of biotechnological processes. The conference concluded with a virtual tour of Biowert Industrie's grass factory.

bl