Advancing green methanol synthesis

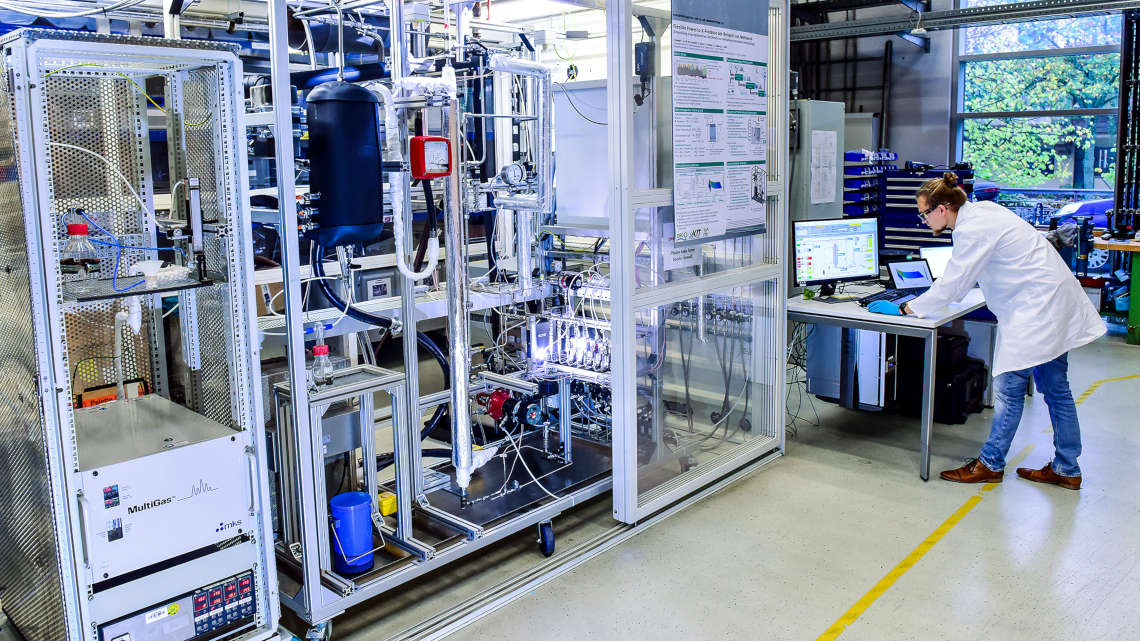

Fraunhofer researchers have developed a miniaturized plant to study the processes involved in the production of methanol from carbon dioxide and hydrogen.

Every year the chemical industry produces around 100 million tonnes of methanol. However, the production of this important basic chemical is based on fossil raw materials and causes high CO2 emissions. The exact opposite would be conceivable: Methanol can also be produced from green hydrogen and carbon dioxide. But process requirements for producing green methanol on an industrial scale have been little researched to date. The project "Power-to-Methanol - Grünes Methanol", funded by the Federal Ministry of Economics, wants to change this. An important milestone for this is a miniature plant for methanol synthesis, which is packed to the brim with measurement technology.

Unusual dynamic process

Test facility with the latest measuring technology

The miniature synthesis plant therefore represents, true to scale, an industrial synthesis plant. Thanks to a few tricks, it has a comparable thermal and reaction kinetic behavior. A very precise measuring technique - including infrared spectroscopy and a new type of fibre optic method - records how the plant behaves in dynamic operation with unconventional gas compositions. In parallel, the researchers have developed a simulation platform with which they can calculate the parameters under such process conditions.

Scientific and economic feasibility

"The aim of the project is a scientific and economic examination of the feasibility of methanol synthesis from renewable energies and biogenic CO2 from a biorefinery for the production of renewable ethanol," summarizes project leader Max Hadrich from Fraunhofer ISE. Other research partners in the project are Fraunhofer UMSICHT, TU Bergakademie Freiberg and the companies CropEnergies, Clariant and Thyssenkrupp Industrial Solutions. The project is being coordinated by DECHEMA e.V. The common hope: if it is possible to develop a stable process control system, green methanol could in future be used as an energy storage medium, fuel or basic chemical and relieve the climate.