‘It is our mission to revolutionize the construction industry’

Joost MeyerOccupation:

Designer, sculptor, and scientist

Position:

Founder of the Aachen-based company Willowprint

Occupation:

Designer, sculptor, and scientist

Position:

Founder of the Aachen-based company Willowprint

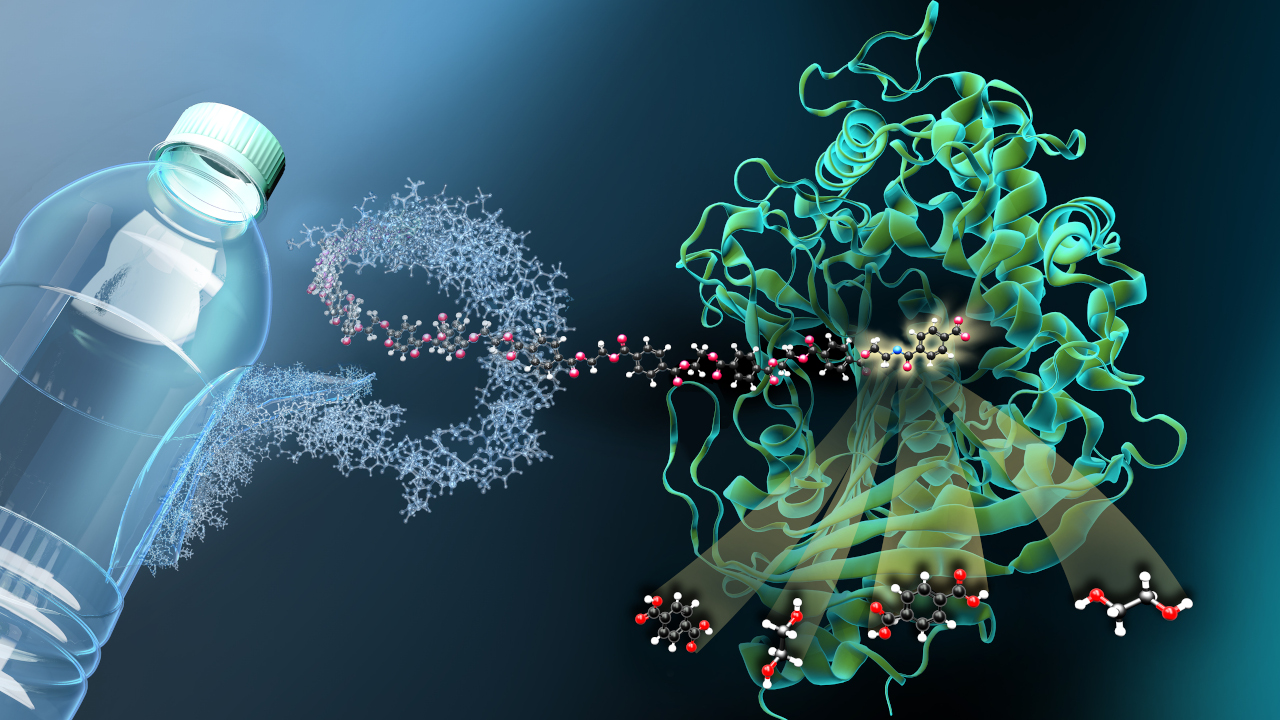

Wood fibers are the raw material the company Willowprint uses in 3D printing to create a building material that is completely recyclable and compostable.

According to the German Environmental Aid Association, the construction sector accounts for 40% of total raw material consumption and 12% of greenhouse gas emissions in Germany, making it a major contributor to global warming. With 3D printing technology and bio-based materials, Willowprint aims to make the construction industry more sustainable – using willow paste. The so-called Willowpaste, developed by the Aachen-based company founded by Joost Meyer, is made from wood fibers – an industrial by-product – and can be used with a 3D printer to manufacture various products.

How did the idea come about to develop materials for the construction industry using willow paste and 3D printing?

During my research work at the Institute of Landscape Architecture at RWTH Aachen University, I focused extensively on the Cologne Forest Laboratory (Waldlabor Köln) and the potential of future forest landscapes and forms. In 2021, the idea emerged to use fast-growing wood – including willow – for 3D printing. My long-time colleague and 3D printing expert Federico Garrido just said, “That’s not possible, no one’s doing that.” That was when I knew we had to try it – and the idea for Willowprint, sustainable 3D printing with wood, was born.

What exactly is Willowpaste (3D printing paste) made of?

Essentially, the paste consists of wood components, which we now source from residues from the wood industry. Natural binders and stabilizers are added to give the paste its smoothness during printing and its required strength once hardened. This sets our technology apart from many others that use less environmentally friendly additives. Together with RWTH Innovation, we were able to file a patent for both the formulation and the technology.

What advantages does 3D printing offer? Can Willowpaste also be used without it?

Additive manufacturing (the 3D printing process) offers many advantages over conventional methods – when used correctly. We use by-products from the wood industry to create a building material for the future. The process generates minimal waste, requires no additional formwork or molds, and enables the printing of objects that already incorporate multiple design aspects. After production, the individual modules can be assembled – like Lego – into large-scale structures. It's the combination of design, technology, and material that makes Willowprint so unique.

How can Willowpaste be used in the construction industry?

Within the Willowprint research project, we’ve already printed a variety of design objects – such as small pieces of furniture, lamps, and urns. Our vision is to manufacture large-scale components for use in temporary architecture. These could include trade fair booths, eco-resort bungalows, or temporary student housing in times of housing shortages. Achieving this still requires further research and development.

We started the project from scratch four years ago and depend on external funding. On our journey toward becoming a start-up, we’ve received support from RWTH Aachen University and the Innovation Promotion Agency of North Rhine-Westphalia, co-financed by the EU. That support made the project possible in the first place.

What ecological advantages does the material offer?

The material consists exclusively of natural raw materials – residues from the wood industry – and is completely recyclable and compostable. That has been important to us from the very beginning. During the development of the technology – for example, to print larger and more stable structures – we continuously carried out sustainability tests. We even used standard household compost boxes to “feed” worms with our material. The worms tolerated it well, and humus was produced as a result. Of course, that’s just a starting point and still needs further testing and validation. Through our work, we want to contribute to the circular use of biogenic raw materials.

Interview: Lea Holzamer