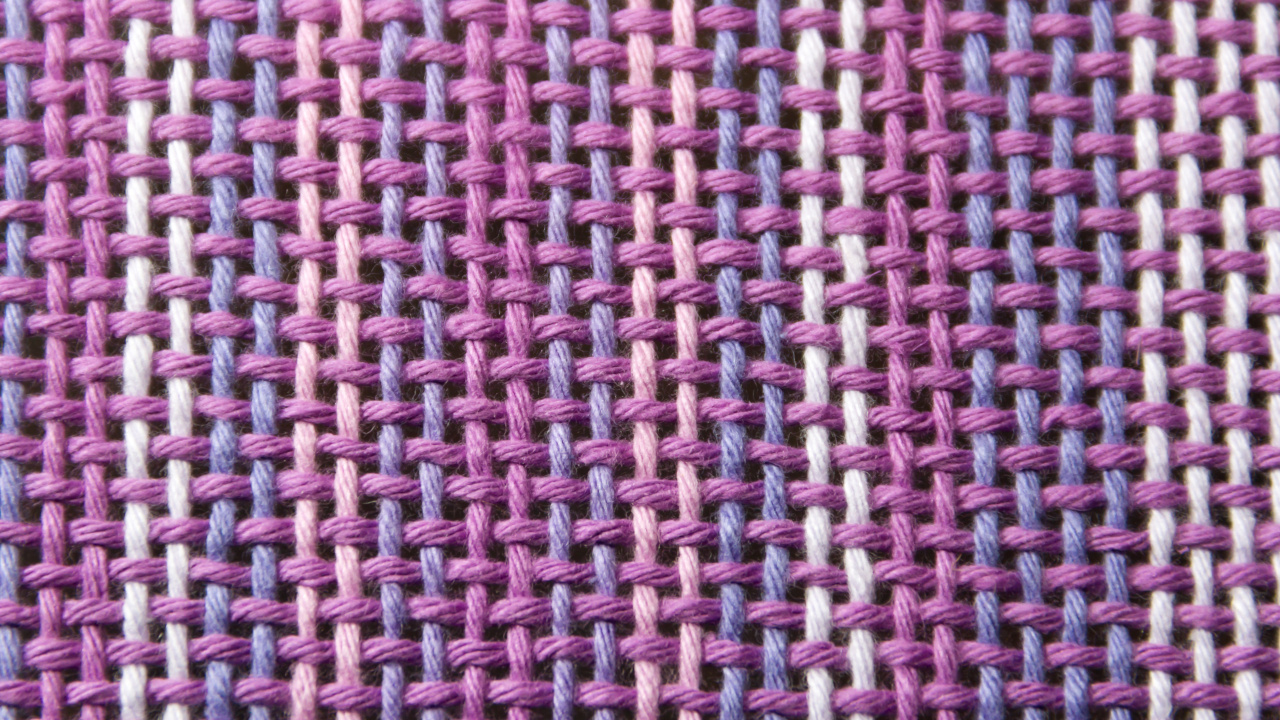

Bio-based textile fibres made from lignin

The European BioFibreLoop project aims to establish lignin as a bio-based fibre source for the textile industry. The main challenge is to establish a supply chain.

Source

Gabriela Bertolini/adobe.stock.com

The combination of lignin and cellulose in spun fibres opens up a bio-based alternative for the textile industry.

The participants in the project, which has been running since the beginning of 2024, have now met to discuss the next steps.

lh