What is a digital twin?

A crisis in space travel in 1970 is considered to be the trigger for the existence of digital twins today: During the Apollo 13 mission, there was an explosion in the command module's oxygen tank. NASA aborted the original mission to land on the moon and made it a top priority to bring the crew back to Earth safely. Engineers on Earth used a combination of physical replicas and simulated models of the space shuttle. This allowed them to recreate the conditions on board and work out solutions for oxygen deprivation, energy consumption and temperature control in real time. The crew on board implemented the solutions virtually tested on Earth on site and returned safely to Earth at the end.

This idea of using the digital copy of a physical system for real-time monitoring and problem solving was new. It laid the foundation for the technologies we know today as digital twins, which are used in a variety of industries.

Today, a digital twin is defined as a digital representation of a physical object, process or system with bidirectional (i.e. two-way) data flow. A digital twin could, for example, be the image of a bioreactor that helps to create optimal production conditions.

As a rule, a digital twin is constantly updated with data from sensors, IoT (Internet of Things) devices or other sources. This allows possible scenarios to be simulated in order to find the optimal path without having to test countless variants in real life.

‘Twins, models and shadows’

Digital twins must be distinguished from digital models and digital shadows, even if all three concepts are sometimes referred to as digital twins in everyday life:

- A digital model is the static or isolated digital replica of an object or system that has no direct data flow to its real-life counterpart. This means that there is no real-time comparison with the real object. A digital model is often used for design purposes, for example to model how algae grow under certain conditions in a bioreactor and to select the optimal conditions.

- A digital shadow is a digital representation of an object or system in which the real object sends data to the digital shadow on one side. However, there is no feedback or control. Digital shadows are therefore often used for monitoring or documentation purposes - for example, a logistics platform that displays vehicle location data.

- With a digital twin, on the other hand, data flows in both directions and in real time. For example, the digital twin of a field receives data on the condition of the soil from sensors placed there, which the twin then analyses and uses to make recommendations on where to fertilize or irrigate.

Page 2 of 4

What are digital twins used for?

Product development: Digital twins make it possible to produce virtual prototypes. Traditionally, a new physical prototype has to be produced for every design change. This is time-consuming and expensive. With digital twins, numerous designs can initially be developed and optimized virtually so that only those that are particularly promising in the simulated application environment need to be built in real life. A virtual prototype can also be used to analyze how it behaves in different environments, for example in particularly cold or damp locations. This allows functionality and service life to be optimized under realistic conditions. Because a digital twin receives real-time data even after the real product has been put into operation, conclusions can be drawn as to how future product generations can be further improved.

Life cycle analysis: Digital twins can map the entire life cycle of a product, from development and production through to use and disposal. The virtual analyses make it possible to develop products more sustainably by identifying efficient production methods and minimizing the use of resources. The twins also enable better maintenance and recycling strategies to be incorporated during product development. The real-time data that is fed back shows where the simulation may have been incomplete and where further improvements are possible.

Real-time monitoring and control: Digital twins continuously receive data from sensors, IoT devices and other sources that reflect the current state of a process or system. This makes it possible to monitor all parameters and interactions in real time and detect deviations immediately. The situation can be analyzed automatically using the digital twin. In addition, several possible reactions can be simulated and the best possible control of the process can be initiated. This applies both to cases in which a short-term disruption upsets the system and to cases in which framework parameters change slowly. The latter is thus detected at an early stage and enables countermeasures to be taken before any problems become apparent.

Predictive maintenance: Predictive maintenance is possible thanks to real-time monitoring. Digital twins are used in manufacturing plants, for example, to monitor machines and production lines and schedule maintenance based on actual need rather than fixed intervals. As the twins continuously evaluate the system's real-time data, they detect anomalies - such as unexpected vibrations or temperature increases - that are due to wear at an early stage. In addition, maintenance times can be realistically predicted because the digital twin can use historical data to simulate when wear will be so great that it is advisable to replace the component. This means that unnecessary maintenance can be avoided, as can unplanned downtime due to components failing unexpectedly.

Visualisation and process understanding: Digital twins can be used to better understand and visualise processes in several ways. For example, they make it possible to analyse relationships and dependencies between process parameters in detail. In the event of deviations or errors, causes can be precisely identified, for instance by comparing actual data with simulation models. Intuitive dashboards, 3D models or virtual or augmented reality also make it possible to see the entire process, including areas that are normally invisible, such as temperature and pressure curves.

Networking a large IoT infrastructure: Digital twins can play a central role in large IoT infrastructures by serving as an integrative platform to network, manage and optimise devices, systems and processes. The twins collect, organise and analyse data from IoT devices in real time. They present all devices and systems in a standardised way and reduce the number of data islands because all information converges in a central model. They make it possible to prioritise critical systems in real time. Energy consumption and network bandwidth can also be optimised. One example is an intelligent greenhouse in which digital twins monitor the environmental conditions and growth, are linked to the energy generation system in order to link controllable energy requirements to available solar energy, as well as optimise harvest times and logistics.

Page 3 of 4

How does a digital twin work?

The focus is on four central steps: modelling, monitoring, data transfer and updating.

1) The first step in creating a digital twin is to develop a precise model of the real system, for example a production plant in which algae are cultivated in large bioreactors. The aim is to have these algae produce biofuels efficiently. In this step, the plant is first constructed virtually: the geometry of the reactors, the chemical processes within the algae cells, the flow dynamics of the water and the supply of light and nutrients. This digital prototype forms the basis for accurately modelling the real system. Engineers and biologists combine physical laws, biochemical reactions and mechanical processes to create a model that is as accurate as possible. The result is a simulation that accurately reflects how the system should function under different conditions.

2) During operation, a digital twin lives from data, and this comes from monitoring the real system. Numerous sensors are installed in the algae plant: they measure temperature, pH value, light intensity, CO2 concentration and nutrient content. These parameters influence the growth of the algae and therefore the efficiency of fuel production. The sensors continuously supply data from the bioreactor. Modern IoT technologies make it possible for these measurements to be taken in real time. This makes the real system transparent and all relevant states can be measured. For example, the sensors record whether the nutrient ratio changes or the temperature deviates from the ideal conditions.

3) In the next step, the sensor data is transferred to the digital twin. This transmission takes place in real time, often via wireless networks or directly via a cloud infrastructure. In the biofuel plant, this means that any change, such as a sudden increase in the CO2 content in the reactor, is immediately forwarded to the digital twin. It acts as a central data platform and integrates information from various sources. Data transmission is crucial, as this is the only way the digital twin can accurately depict reality. Thanks to modern technologies such as 5G networks and powerful databases, even large volumes of data can be processed almost instantaneously.

4) The final step turns the digital twin into a dynamic tool: the sensor data is used to continuously update the model. Every change in the real system is immediately reflected in the virtual model of the twin. In the algae example, a drop in light intensity due to a defective lighting unit would be visible in the digital twin. The model then adjusts the simulation of the algae growth rate. This real-time update makes it possible not only to monitor current conditions, but also to make predictions: How does a permanently low nutrient content affect production? Do certain processes need to be adjusted to maximise efficiency?

The result is a highly dynamic platform that not only monitors processes, but also identifies optimisation opportunities.

Page 4 of 4

Practical examples and outlooks from the bioeconomy

The Fraunhofer project COGNAC (Cognitive Agriculture) is an innovative example of the use of digital twins in agriculture. The aim of the project is to make agricultural processes more efficient, resource-saving and sustainable. The digital twin of a field was developed for this purpose. Sensors in the soil and on plants continuously measure important parameters such as soil moisture, nutrient content, temperature and weather conditions. The digital twin integrates this data and simulates the current and future conditions of the field. For example, it can predict when and how much water or fertiliser is needed. Based on these simulations, farmers receive precise recommendations for action to optimise their cultivation and use resources efficiently. They need less water and fertiliser, ensure better yields through optimised growing conditions and minimise negative environmental impacts.

The Beehyve community project aims to support beekeepers in a similar way. The aim of this project is to facilitate the work of beekeepers and contribute to the sustainability and protection of bees through the digitalisation of beehives. Sensors in the beehive continuously record data such as temperature, humidity, air quality and CO2 concentration. These parameters are crucial for the health and well-being of the bee colonies. The collected data is integrated into a digital twin of the beehive. Anomalies, such as a change in temperature that indicates a disease or a swarm, can be recognised at an early stage. Recommendations for necessary measures are also generated.

The Fruity-Twin project is a joint endeavour between the Leibniz Institute for Agricultural Engineering and Bioeconomy (ATB) in Potsdam and the University of Bremen. The aim of the project is to optimise the storage of fruit, especially apples, through the use of digital twins and thus reduce food waste. Sensors are used within the cold storage facilities to continuously measure parameters such as temperature, humidity and condensation on the surface of the fruit. This data is essential, as condensation on fruit favours the growth of microorganisms, while low humidity leads to a loss of quality. The recorded data is used to create a virtual image of the storage room and the stored fruit. This digital twin simulates the physical processes, in particular heat and mass transfer, which influence condensation. The simulation can be used to determine optimum storage conditions that minimise condensation and therefore extend the shelf life of the fruit. The digital twin also enables storage parameters to be adjusted in real time in order to maintain the quality of the fruit.

The BMBF-funded DigInBio project aims to significantly accelerate biotechnological development processes through digitalisation, automation and miniaturisation. Researchers at FZ Jülich, TU Munich and the University of Hanover have set up demonstration laboratories in which modern technologies - such as automated microcultivation platforms, laboratory robotics and digital workflows - help to make the complex processes involved in bioprocess development more efficient. By networking laboratory equipment using standardised interfaces such as SiLA2, a central data management system is implemented that supports the optimisation and control of the entire process, from the selection of suitable microorganisms to production. Although digital twins are not a direct project goal, the digital structure and continuous mapping of laboratory processes can be interpreted as a preliminary stage of a digital twin - a virtual clone of the real laboratory that could be used for simulations and optimisations.

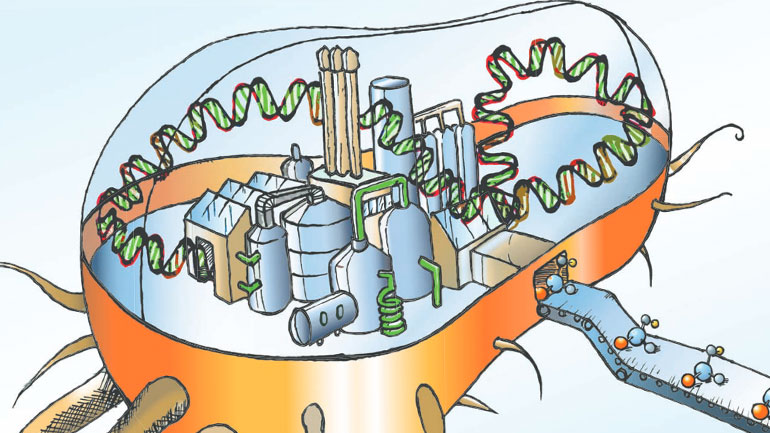

Digital twins also play a central role in smart biofactories. They combine physical laboratory equipment, data platforms and mathematical models in a digital infrastructure to make processes more efficient and sustainable. Biological and chemical processes are mapped using mathematical models and process simulations.

Machine learning and artificial intelligence analyse complex parameters and help to describe the processes and make predictions.

Megacomplex digital twins

- The European Digital Ocean Twin (EU DTO) is a virtual replica of Europe's marine and coastal environments. It integrates real-time and historical data from thousands of sensors worldwide as well as satellite information. This data is combined with numerical modelling to simulate past, present and future ocean conditions. This makes it possible to create high-resolution, multidimensional representations of the ocean that include physical, chemical, biological, socio-ecological and economic aspects. Scientists can use the digital twin to predict how climate change and human activities will affect marine ecosystems, such as seagrass beds or tuna migrations. Companies can use the digital twin to optimise the planning of aquaculture sites, for example, by taking into account long-term predictions of salinity, plankton distribution, currents and extreme heat events.

In June 2024, the first pre-operational platform of the EU DTO was presented at the Digital Ocean Forum. This platform allows users to test the capabilities of the digital twin and provide feedback for further development. - The EU initiative Destination Earth (DestinE) goes one step further. It aims to develop a high-precision digital twin of the Earth that can be used to monitor, model and simulate natural phenomena and human activities. Through precise simulations, the effects of climate change can be better understood and appropriate countermeasures developed. The simulation of extreme weather events would make it possible to issue early warnings and take protective measures.

The second phase of DestinE was launched in June 2024 and will run until June 2026. In this phase, the infrastructure will be further developed to provide a complete digital twin of the Earth by 2030.