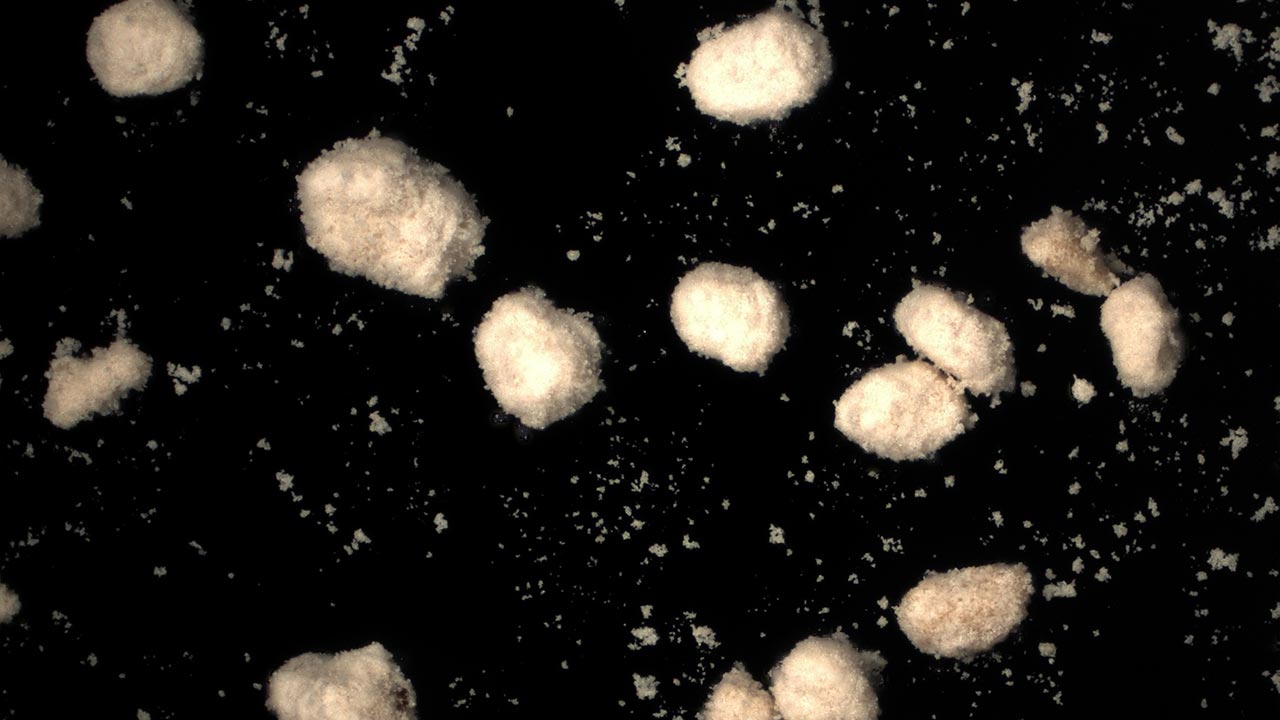

Xylan and lignin from beech wood

A pilot plant for the production of two biobased pharmaceutical raw materials has performed well in test operation.

The Xylosolv research project has developed the extraction of xylan from beech wood from laboratory scale to pilot plant. In 2025, a biorefinery yet to be built will finally produce the valuable carbohydrates on an industrial scale. At the same time, the process can also make the wood component lignin usable.

Two becomes one

Researchers from the Fraunhofer Center for Chemical-Biotechnological Processes (CBP) and the companies HV-Polysaccharides (HVP) and Glatt Ingenieurtechnik (GIT) have joined forces to not only scale up two individual processes, but to combine them: Thuringia-based HV-Polysaccharides had previously developed a hydrothermal method to extract particularly high-quality xylan from wood. CBP from Leuna, together with Linde, had researched a process to extract high-purity lignin from beech wood using only water, alcohol, pressure and heat. However, both processes produced a lot of residual material, which was neither particularly sustainable nor economical.

The combination of both extractions now uses the raw material wood much more comprehensively and thus also has better chances of surviving on the market. Originally, the two-year project was intended to produce a continuously controlled process. This would have been possible in principle, but with a product quality that would not have been sufficient for pharmaceutical applications. However, the participants succeeded in developing a multistage process to extract both carbohydrates from the wood in high quality. The yield is high - and is achieved entirely without organic solvents.

Currently only remaining stocks on the market

Earlier processes for extracting xylan from beech wood failed to deliver consistently high product quality or to prove themselves on a large scale. The most recent process was discarded due to environmental, occupational health and safety considerations, so that the pharmaceutical industry currently only has residual stocks of xylan. HVP is therefore now planning to set up a biorefinery at the Bucha site that will use the new process.

The Xylosolv research project was funded by the German Federal Ministry of Food and Agriculture (BMEL) through the project management agency Fachagentur Nachwachsende Rohstoffe e. V. (FNR).

bl