Turning CO2 and green energy into green chemistry

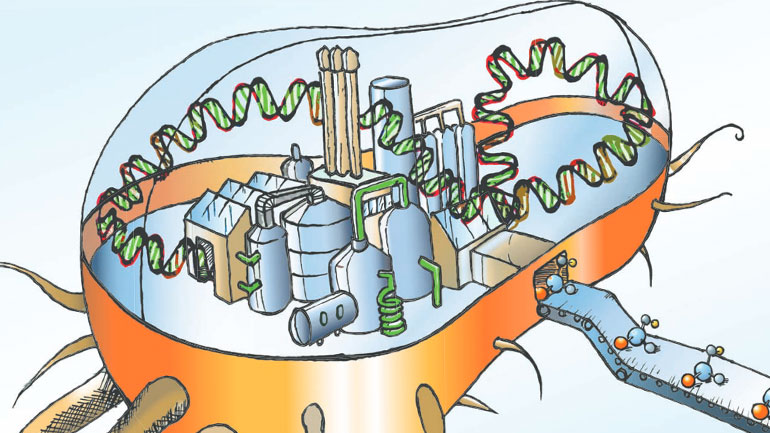

Evonik and Siemens are developing a new technology that uses bacteria and electricity from renewable resources to convert carbon dioxide (CO2) into specialty chemicals.

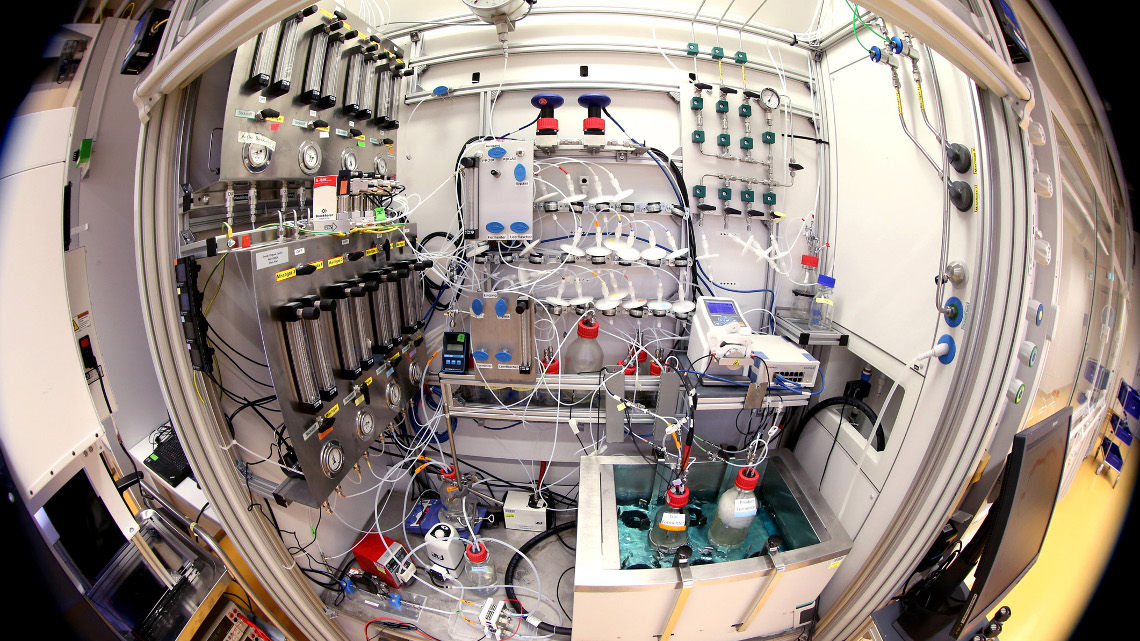

Evonik and Siemens have entered into a joint research project called Rheticus. Approximately 20 researchers from both companies will be working on electrolysis and fermentation processes for the next two years. The first test plant is scheduled to go on stream by 2021 at the Evonik facility in Marl, Germany. This plant produces chemicals such as butanol and hexanol – both of which are the basis for special plastics and food supplements.

A new cost-effective and environmentally-friendly production

“We are developing a platform that will allow us to produce chemical products in a much more cost-effective and environmentally-friendly way than we do today”, explains Günter Schmid, technical project responsible of Siemens Corporate Technology. The new technology will combine multiple benefits: It enables chemicals to be produced sustainably, it also serves as an energy store, can respond to power fluctuations and help stabilize the grid.

“With the Rheticus platform, we want to demonstrate that artificial photosynthesis is feasible”, adds Thomas Haas, who is responsible for the project in Evonik’s strategic research department Creavis. Artificial photosynthesis describes a process in which CO2 and water are converted into chemicals using a combination of chemical and biological steps.

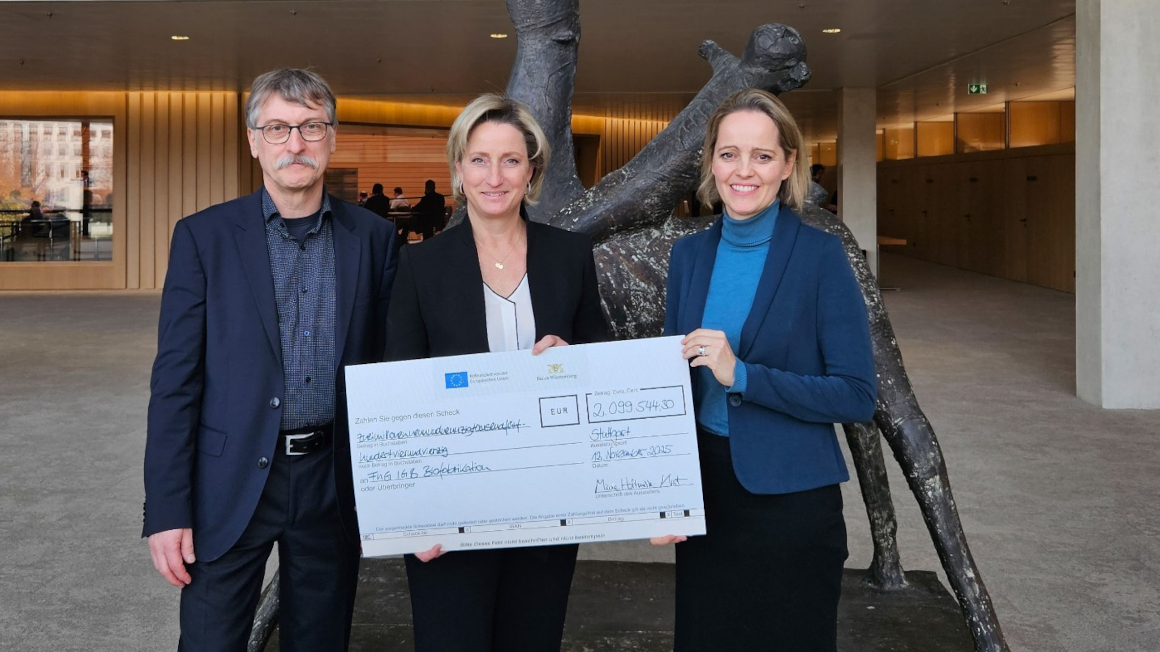

Federally funded initiative for Energy transition

Rheticus is linked to the Kopernikus Initiative for the energy transition in Germany, which is seeking new solutions to restructure the energy system. The Rheticus project will receive €2.8 million in funding from Germany’s Federal Ministry of Education and Research (BMBF).

Merging core competencies

Siemens and Evonik are each contributing their own core competencies to this research collaboration. Siemens is providing the electrolysis technology, which is used in the first step to convert carbon dioxide and water into hydrogen and carbon monoxide (CO) using electricity. Evonik is contributing the fermentation process, converting gases containing CO into useful products by metabolic processes with the aid of special micro-organisms. In the Rheticus project, these two steps – electrolysis and fermentation – are scaled up from the laboratory and combined in a technical test facility.

Future full of potential

The next stage could see a plant with a production capacity of up to 20,000 tonnes a year. However, the adaptability of the process and technology will make it simple to scale plants to the desired size - depending on local conditions. In future, they could be installed anywhere where there is a source of CO2, for instance power plant waste gas or biogas. There is also the potential to manufacture other specialty chemicals or fuels.

jmr