Thinking big with smart bioprocess technology

Smart models, sophisticated measurement technology and automated workflows: At the BioProScale conference in Berlin, stakeholders from science and industry exchanged views on the most important trends in industrial biotech production.

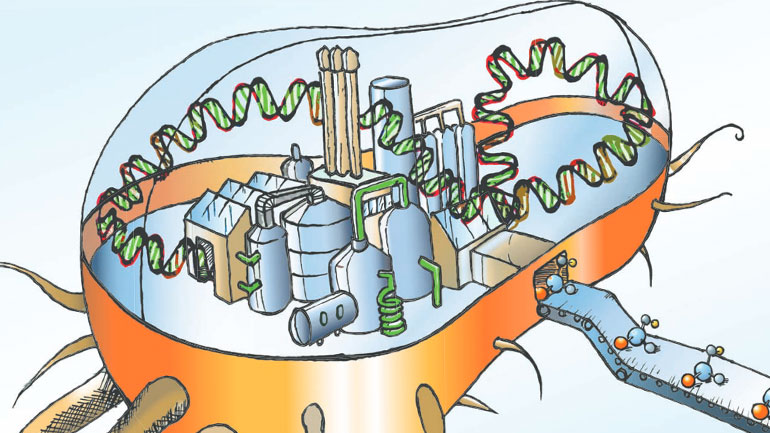

Industrial biotechnology utilises microorganisms or individual biomolecules such as enzymes in bioprocesses as the basis for the industrial production of chemicals, biopharmaceuticals or food additives. The key players are cells as living factories that can produce a desired product in large quantities in closed bioreactors. Developing bioprocesses in such a way that the biotechnological production of a product is optimised is very time-consuming and complex.

Specialist conference for the scale-up of bioprocesses

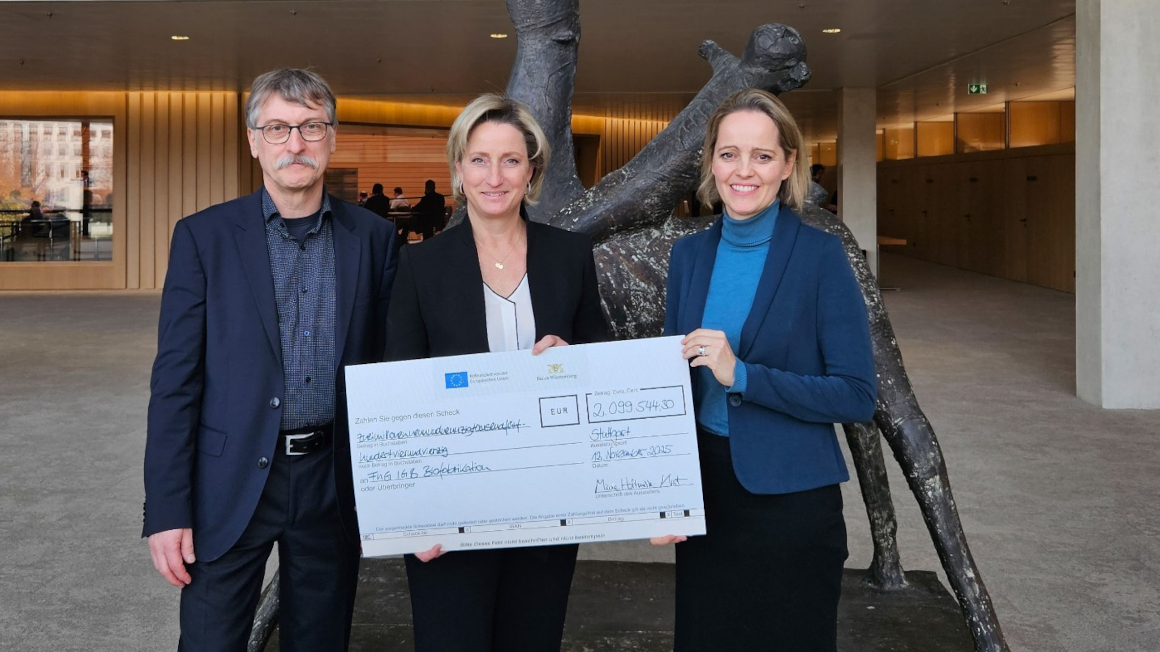

"Efficient bioprocess development forms the basis for a sustainable bioeconomy and the cost-effective production of therapeutics," says Peter Neubauer, Head of the Department of Bioprocess Engineering at Technische Universität (TU) Berlin. "Highly accelerated development cycles are only possible if we focus on completely new approaches and develop new technologies," says Neubauer. He is one of the world's pioneers in automated bioprocess development and has set up the Future Laboratory for AI-supported Bioprocess Development (KIWI-biolab), which is funded by the German Federal Ministry of Education and Research.

A major challenge in biotechnology is the scaling up of processes from a small laboratory bioreactor to "brewing" in huge steel containers. In 2009, Neubauer therefore initiated the BioProScale Symposium to create a platform where the latest trends in scale-up can be discussed. The event has since become a forum with international appeal for bioprocess engineering experts. Around 200 stakeholders from industry and science came to the Langenbeck-Virchow-Haus on the Charité campus in Berlin-Mitte from 9 to 11 April for the eighth edition, which was organised by TU Berlin together with Bio-PAT e.V. and BioProScale e.V..

Technology transfer

It became clear at the conference that digitalisation, automation and modelling now play a crucial role in all phases of bioprocess development. "Data science is the big trend in scale-up, and the coronavirus pandemic has given it another boost," says Emmanuel Anane in an interview with bioökonomie.de. In Denmark, he works for Fujifilm Diosynth Biotechnologies, a contract manufacturer for the pharmaceutical industry. Anane is involved in the production of biopharmaceuticals – such as antibodies – using hamster cells (CHO). These animal cells are usually cultivated in disposable bioreactors with a volume of 2,000 litres. "But when demand increases, processes in 20,000-litre steel tanks will become interesting". In order to simulate such increases in scale, Anane engages in technology transfer: "We transfer information from one context to another in order to simulate processes on an industrial scale using mathematical models."

One major challenge is the often incomplete data sets that customers supply to contract manufacturers. Artificial intelligence could provide a remedy, among other things. "AI-based algorithms could predict at which point in the bioprocess samples should be taken – that would be smart and extremely helpful for efficient data collection," says Anane. A team led by Frédéric de Lapierre from Munich University of Applied Sciences is also working with AI-based solutions. He presented a machine learning algorithm that automatically prepares the composition of the nutrient solution in a microbioreactor, checks growth and makes suggestions for improved media mixtures.

Video: The laboratory of the future – digitalisation of biotechnology

(automatically translated subtitles available on external page)

Automated laboratory platform

Marco Oldiges from Forschungszentrum Jülich explained how bioprocess development can be significantly accelerated through miniaturisation, automation and digitalisation. His team has set up a robot-supported high-throughput platform for automated microbial experiments with funding from the German Federal Ministry of Education and Research, among others.

Hundreds of experiments for the characterisation of microbial production strains run in parallel here. This creates a treasure trove of data that enables the use of machine learning to explore complex solution spaces. The trend is clearly towards the autonomisation of experiments: Algorithms decide how experiments are conducted. The development processes repeatedly go through a cycle of design, production, testing and learning (design-build-test-learn). Oldiges explained the application of this approach using the example of the microbial production of catalytically active inclusion bodies.

High-tech for process analysis

Another thematic focus at BioProScale was on the increasingly important process analytical technology (PAT). This is because it makes it possible to analyse biotechnological production processes in detail, control them in real time where possible and thus make them more efficient. Researchers presented innovative sensor solutions, such as electrochemical sensors or an online sensor based on a lens-free microscope.

Scale-up in the bioeconomy system

Bioeconomy expert Daniela Thrän from the Helmholtz Centre for Environmental Research and DBFZ broadened the perspective on the topic of scale-up and addressed the role of bio-based resources and processes on the path to a climate-neutral industry. She emphasised the importance of closed-loop and cascade concepts in the use of biomass as a limited resource and explained which life cycle analyses are relevant for determining the reduction of greenhouse gas emissions in bioprocesses.

Philipp Graf