Microalgae ink for 3D laser printing

An international research team led by Heidelberg University has succeeded for the first time in obtaining biocompatible materials from microalgae for high-resolution 3D laser printing.

Microalgae not only contain valuable resources. They are also coveted and, above all, efficient biofactories for producing biogenic raw materials for dyes, plastics and biofuel. They only need sunlight, carbon dioxide and water to quickly produce large quantities of biomass. In addition, the cultivation of microalgae binds carbon dioxide. An international research team led by Heidelberg University has now expanded the range of applications for microalgae-based products. A team led by Eva Blasco has succeeded for the first time in using the dyes obtained from microalgae to produce bioinks that are suitable for high-resolution three-dimensional laser printing.

Photoactive dyes in diatoms and green algae

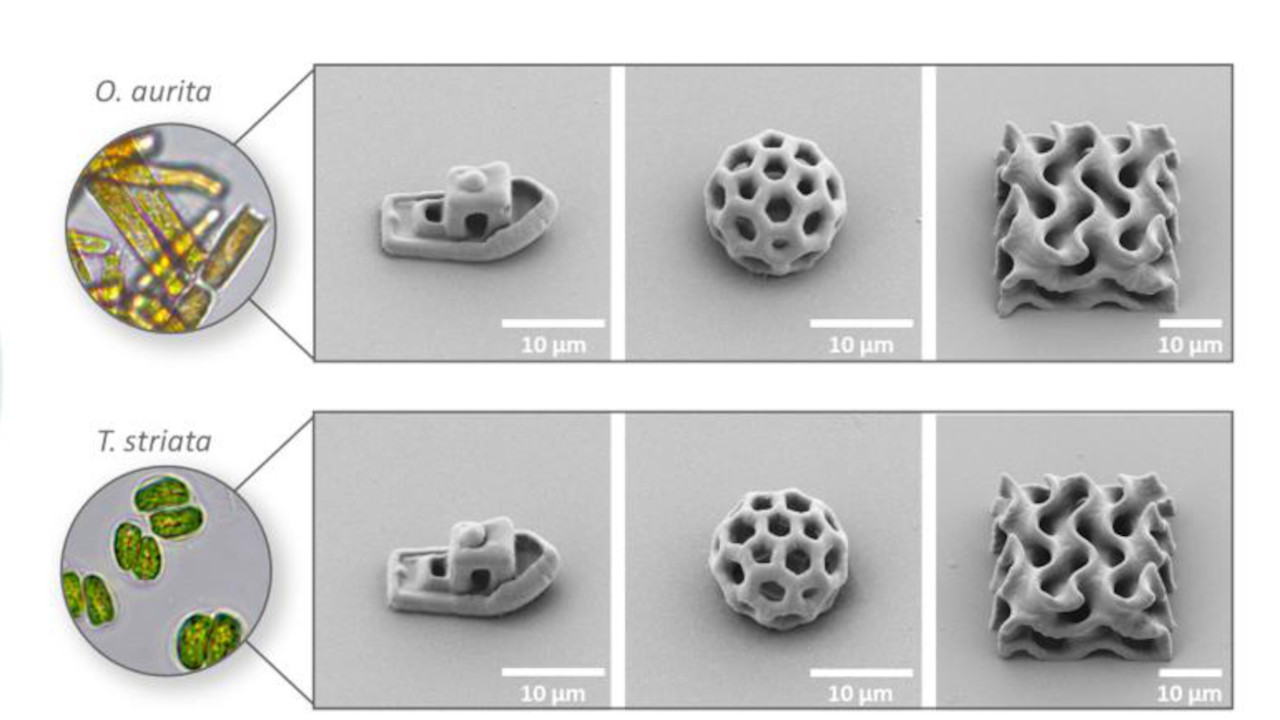

“Despite their advantages, microalgae have hardly been considered as raw materials for light-based 3D printing,” says Eva Blasco from the Institute for Molecular Systems Engineering and Advanced Materials (IMSEAM) at Heidelberg University. As the team reports in the journal "Advanced Materials", the diatom Odontella aurita and the green alga Tetraselmis striata were selected as two species for the production of the bioinks that contain a particularly high amount of fats in the form of triglycerides.

These triglycerides were extracted by the researchers and functionalized with acrylates to enable rapid curing when exposed to light from the laser. The laser beam activates special molecules in the bio-ink, known as photoinitiators. This results in a chemical reaction, which solidifies the ink into a three-dimensional structure. The photoactive green dyes present in the two microalgae proved to be particularly suitable as photoinitiators.

Various 3D microstructures produced with bio-ink

The high-precision 3D laser printing process has so far mainly used inks made from petroleum-based polymers. According to the researchers, the newly developed ink system has already been used to produce “various 3D microstructures with high precision and complex features such as overhanging roofs or cavities”. “This allows us to avoid the use of potentially toxic additives such as photoinitiators, which are used in conventional inks,” explains first author Clara Vazquez-Martel, a PhD student in Eva Blasco's research group at IMSEAM.

Biocompatibility of the cell cultures at almost 100%

Using cell cultures, the team also investigated the biocompatibility of the microalgae-based inks. According to the study, the survival rate of the cell cultures was “almost 100%”. “Our results not only open up new possibilities for more sustainable 3D printing with light, but also for life science applications – from three-dimensional cell cultures to biocompatible implants,” says Blasco.

In addition to Heidelberg University, researchers from the Karlsruhe Institute of Technology and the Universidad de Las Palmas on Gran Canaria were also involved in the study.

bb