Living colour for facades

An international research team involving Graz University of Technology is working on integrating microorganisms into facade paints. The aim is to protect the exterior walls of buildings, bind CO2 and break down air pollutants.

The facade walls of buildings are usually made of metal, concrete or wood. They protect, but hardly interact with their surroundings. However, they could take on an important function in the future - if their utilisation is adapted. For example, through microorganisms that not only protect the materials from weathering, but also store CO2 and filter pollutants from the air. An international consortium involving Graz University of Technology (TU), the University of Ljublana and partners from industry is working on a wall paint enriched with microorganisms in the REMEDY project. It is coordinated by the InnoRenew CoE research institute.

Microbial life on facades and roofs

In addition to the ecological functions, there is also a practical one: forecasts by the European Environment Agency assume that facades and roofs with a total area of around 9.4 billion square metres will be renovated or newly built in the EU over the next 25 years. ‘This is a huge potential that we should utilise. Microbiological communities on roofs and facades could take on numerous functions without taking up scarce, undeveloped space,’ says Carole Planchette from the Institute of Fluid Mechanics and Heat Transfer at TU Graz.

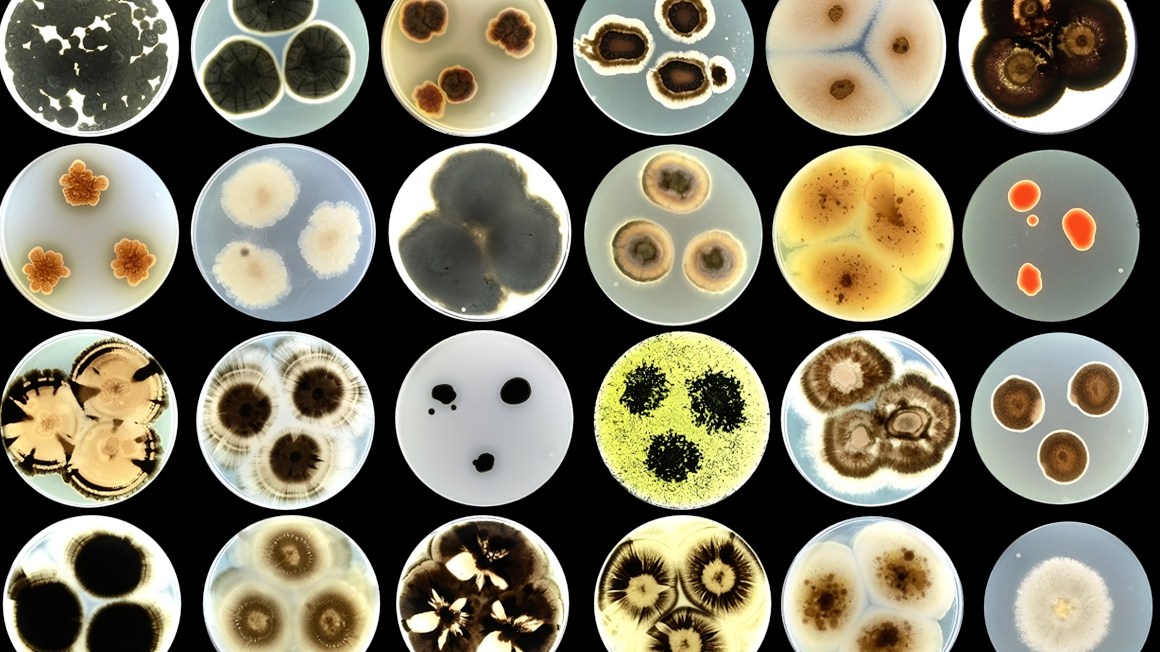

The research team is already looking for suitable microorganisms such as fungi or algae. The idea is to combine several microbes with different properties in order to create a stable community. This should be resistant to harmful microbes and repair superficial cracks independently.

Developing a special ink

A printable ink is also to be developed in which the microorganisms survive on the one hand and which adheres to the outer walls on the other. ‘We opted for inkjet printing because it allows us to apply the living ink very precisely, in a controlled manner and quickly at the same time,’ explains Planchette. A key problem is that the microorganisms have to withstand the stress during the printing process. There is also a risk of them developing into larger clusters, which would rule out inkjet printing. This is why modifications to the technology are already being worked on. However, the TU researcher sees the greatest challenge in being able to make the process reproducible: ‘Because using living - i.e. changing - inks for industrial processes such as inkjet printing, which only tolerate very small parameter fluctuations, is completely uncharted territory.’

The project will run for four years and is being funded with a total of almost three million euros as part of the Pathfinder funding programme.

lh