Chemistry prize for sustainable drug production

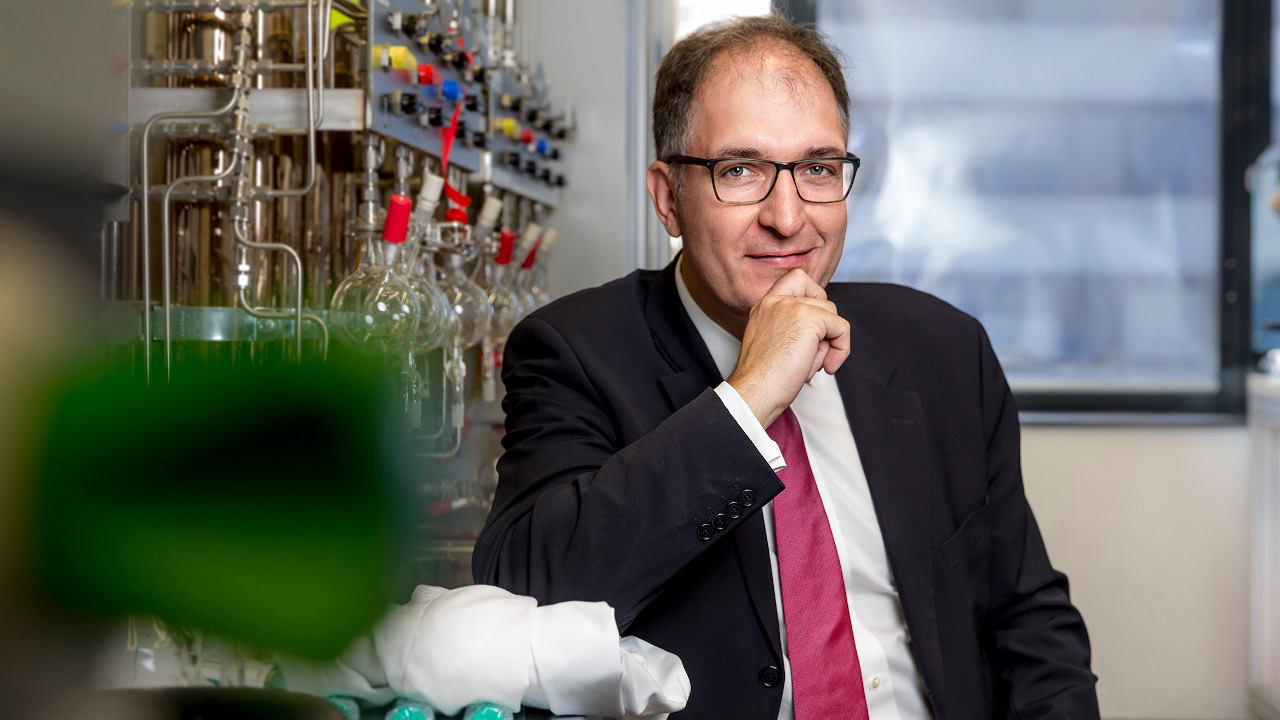

Potsdam biochemist Peter Seeberger has been awarded the International Green Chemistry Prize for the production of a particularly sustainable and cost-effective antimalarial agent.

The consequences of malaria continue to kill around 650,000 people every year - mainly children under the age of five. Although there are effective drugs against the infectious disease, many cannot afford them. However, that could soon change. A team led by biochemist Peter H. Seeberger of the Max Planck Institute of Colloids and Interfaces in Potsdam has developed a chemical process that makes the production of artemisinin, the most important antimalarial agent, not only sustainable but also inexpensive. For this invention, the Potsdam researcher has just been awarded the "ACS Award for Affordable Green Chemistry" by the American Chemical Society (ACS). The award has been honoring outstanding scientific discoveries in the field of green chemistry since 2007.

Faster than nature

Artemisinin is a secondary plant substance that previously had to be extracted at great expense from the leaves of annual mugwort. Seeberger and his team use chopped plant residues as the starting material instead. Likewise, the catalyst comes directly from nature. With the help of the plant's own chlorophyll, the reaction process was accelerated many times over, since purification was also eliminated. In combination with oxygen and light, the team succeeded in producing the active ingredient artemisinin in the laboratory in less than 15 minutes. In nature, the mugwort plant needs three weeks for this.

Producing drugs sustainably and cheaply

"The chemical process we have developed is environmentally friendly and so efficient that we can work in a much more efficient way than the nature we are mimicking," says Seeberger, director of the Biomolecular Systems Department at the Potsdam MPI. "In this way, affordable antimalarial drugs can be produced, and at the same time, our process opens up new possibilities for being able to produce other drugs sustainably and yet more cheaply than before." Also involved in the development of the green production process were chemist Kerry Gilmore of the University of Connecticut, who until recently was a group leader at the Potsdam MPI, and Andreas Seidel-Morgenstern, director of the MPI for Dynamics of Complex Technical Systems in Magdeburg.

In the meantime, production of the antimalarial active ingredient is being driven forward via the U.S.-based spin-off ArtemiFlow, founded by Seeberger and Gilmore. The active ingredient artemisinin is used worldwide not only to treat infections with the causative agent of malaria tropica, but also to treat cancer.

bb