Biogas without carbon dioxide emissions

A new process will use green hydrogen to convert CO2 produced during biogas production into methane.

Methane from biogas plants is supposed to be a more climate-friendly alternative to natural gas. However, besides methane, carbon dioxide is also produced in the biogas plant. Although this is biogenic and therefore less problematic than CO2 from fossil sources, these emissions must be avoided if global warming is to be limited to 1.5 degrees. Fraunhofer researchers have developed a process for this, which they now want to scale up step by step.

Methane from CO2 and green hydrogen

To date, biogas plants produce around 60% methane and 40% CO2 from biomass. The methane is either used on site to generate electricity and heat, or processed and fed into the natural gas grid. In the future, CO2 could also be processed into methane and follow the same path. A team from the Fraunhofer Institute for Microtechnology and Microsystems IMM has developed a process in the ICOCAD I project to produce methane from CO2 and green hydrogen using special catalysts.

Old reaction, new challenges

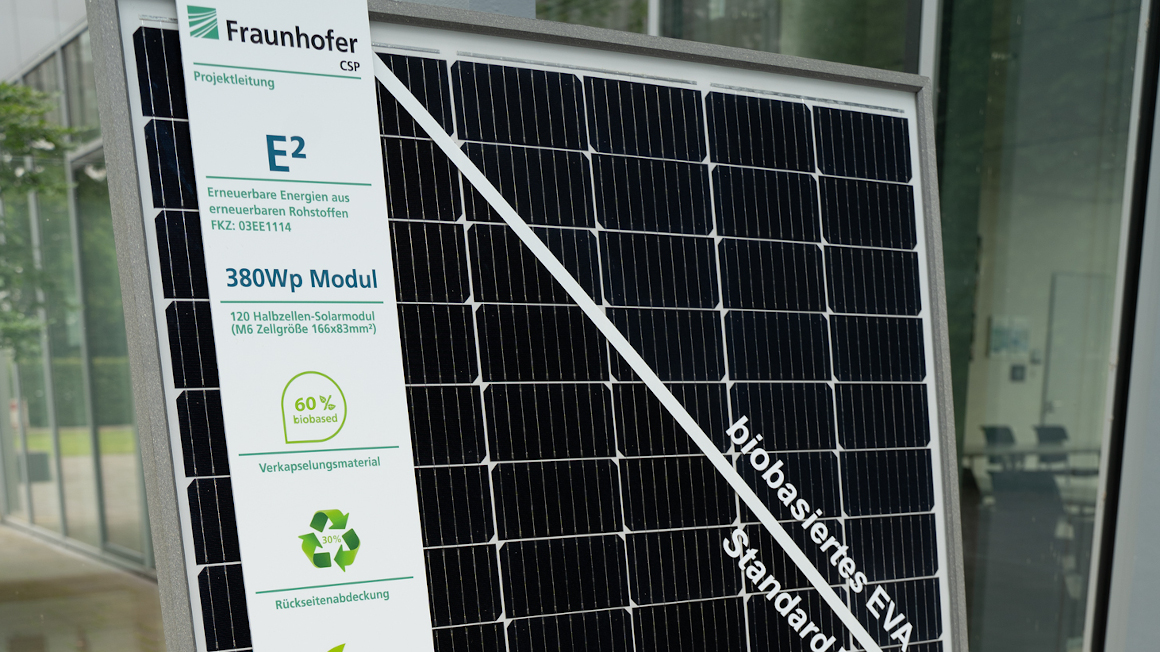

The chemical reaction has been known for a hundred years. The challenge, however, lies with the green hydrogen: It is only green if it is produced with renewable energies - and their availability fluctuates. Therefore, the process for the biogas plant must be able to cope with these fluctuations. Because hydrogen is more difficult to store, the researchers want to store the CO2 temporarily and adjust the process rate accordingly: "We are working on designing the plant flexibly to avoid storing hydrogen as much as possible," explains Christian Bidart from IMM.

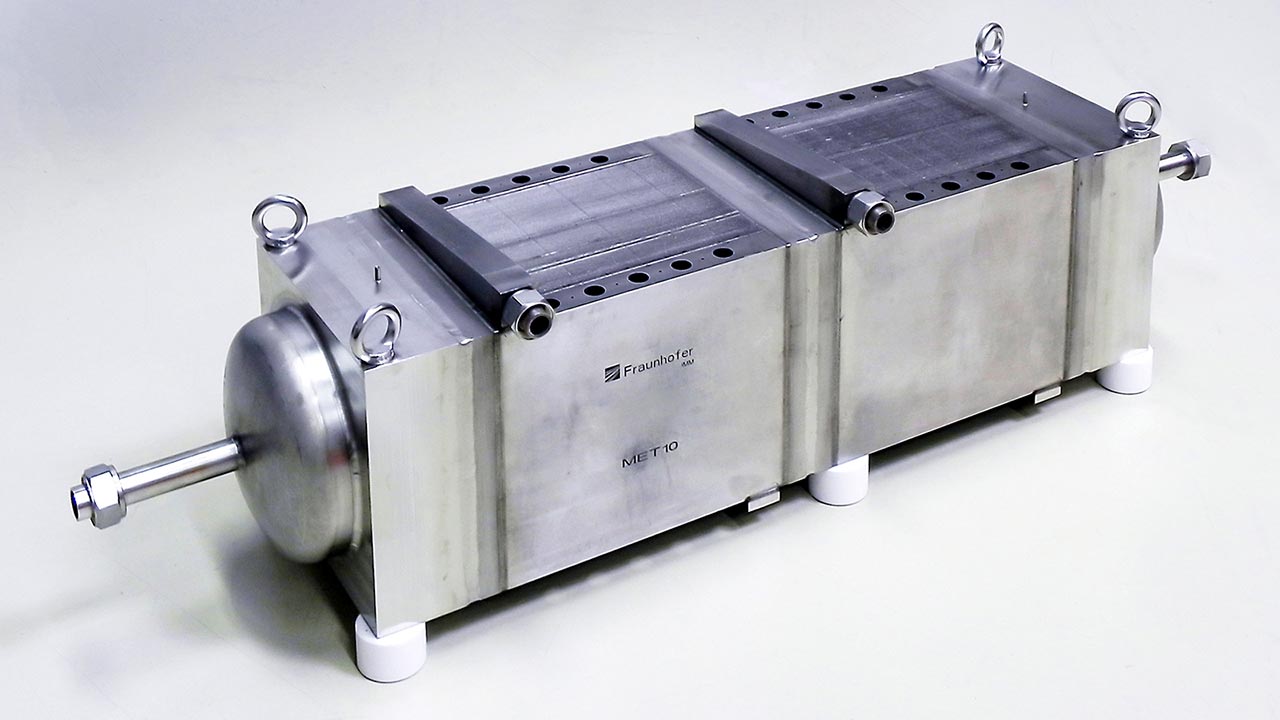

Designed for efficient catalyst use

A critical factor here is the catalyst and its most efficient use. To this end, the researchers have constructed microchannels coated with precious metals through which hydrogen and carbon dioxide flow and react. "In this way, we can increase the contact area of the gases with the catalyst material and reduce the amount of catalyst required," Bidart explains.

Nominal capacity of one to two megawatts in 2026

For an average production of one cubic meter of methane per hour and a thermal output of ten kilowatts, this has already been achieved in the now completed project. Now, the follow-up project ICOCAD II will serve to increase the thermal output by a factor of five by 2023. In further steps, according to the team's plan, an industrial-scale plant with an output of one to two megawatts should then be in operation from 2026.

bl