Bioeconomy Innovation Spaces as a funding concept

The transformation of a petroleum-based economy to sustainable, bio-based processes and products requires far-reaching rethinking. Innovative approaches and new forms of interdisciplinary collaboration are needed to bring relevant research results into application and thus make social as well as industrial reality. Not only different technology and knowledge areas are merging on the way to a bioeconomy, but also entire value chains.

Networking actors in the innovation process

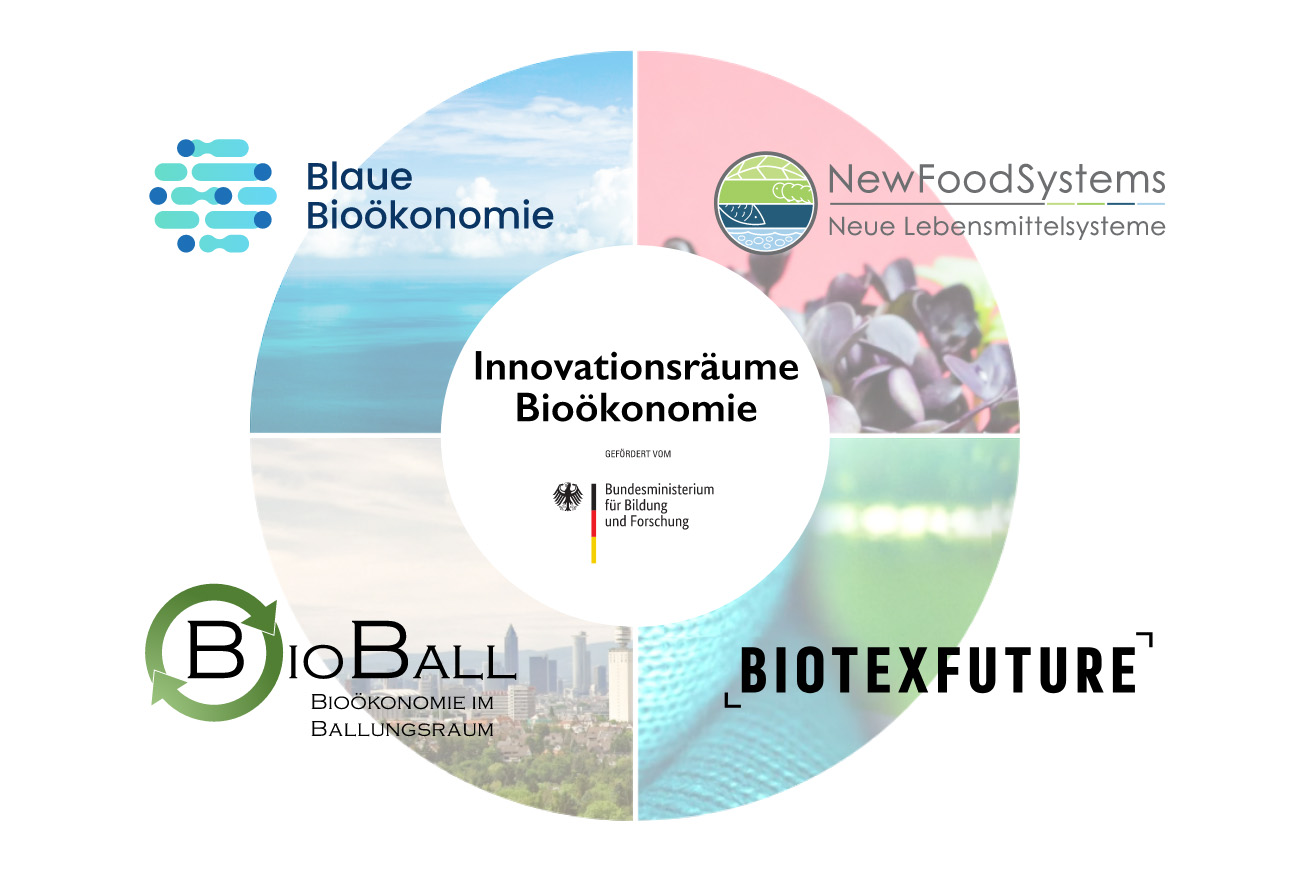

Industries that previously did not collaborate, or hardly collaborated at all, are now starting to do so. In the course of this, new value creation networks are emerging, from which innovative and sustainable products or services follow. In order to create interfaces between research and application in the bioeconomy and to network actors in the innovation process more closely, the Federal Ministry of Education and Research (BMBF) initiated the "Bioeconomy Innovation Spaces" funding concept in 2016.

The aim of the alliances with numerous players from science and industry is to use research results more comprehensively than before and to initiate processes that will become building blocks of a process of change in society as a whole in the sense of the bioeconomy. In a multi-stage selection process (ideas competition and a subsequent conception phase), four consortia finally prevailed with their concepts.

Four innovation spaces implement funding concepts

The four Bioeconomy Innovation Spaces started their implementation phase in 2019 and will initially receive public funding for five years. The BMBF is supporting the innovation spaces with up to 20 million euros each. The alliances are also raising additional funds of their own amounting to millions. The four Bioeconomy Innovation Spaces deal with the topics of food and feed, textiles, the marine bioeconomy and the urban bioeconomy in the context of the circular economy. In this topic dossier, the innovation spaces are portrayed and the research and development activities are examined in more detail.

Page 2 of 5

BIOTEXFUTURE - Shaping a bio-based textile industry

The innovation space BIOTEXFUTURE pursues the goal of producing biobased textiles based on sustainable raw material cycles. The network of more than 70 partners is coordinated by RWTH Aachen University and the sporting goods manufacturer Adidas.

The innovation space at a glance

Objective: To convert the textile value chain from petroleum-based to biobased

Partner: 75 partners (approx. 2/3 companies and 1/3 universities and research institutions), including 16 with project participation

Coordination: Adidas AG (Jan Hill and Chris Holmes) and RWTH Aachen (Prof. Dr. Thomas Gries and Prof. Dr. Roger Häußling)

BMBF funding: up to 20 million euros

Duration: November 2019 to December 2025

Website: biotexfuture.de

Every year, around 120 million tons of textile fibers are produced worldwide - 73 % of which are synthetic man-made fibers that are predominantly petroleum-based. The stakeholders in the BIOTEXFUTURE innovation space would like to contribute to converting this value chain to bio-based raw materials. A holistically sustainable basis for biobased textile fibers is already available, the participants emphasize. The task now is to establish the sustainable value chains throughout the industry.

Bio-based materials, coatings and processes

For this to succeed, the projects will develop bio-based materials, coatings and processes by improving existing production routes and researching new fibers and manufacturing processes. Natural polymers such as cellulose, among others, can also serve as starting materials for high-performance fibers. Polymers synthesized from renewable raw materials, such as polylactic acid (PLA), represent the second generation of biobased raw materials.

The ideal concept in terms of sustainability is residue-based biopolymers such as polyhydroxybutyric acid (PHB), which can come from agricultural residues or residual streams from the food industry, for example. The processes involved range from the extraction of raw materials and the processing of fibers and yarns to the production of textiles. The work of the innovation space is to result in product prototypes.

The research projects are spread over four research fields:

• Textile finishing

• Product and process management

• Recycling management

• Development of substrates and materials

Create a change in awareness in the industry

The close interlinking of the research projects with stakeholders along the production routes is intended to help anchor the existing opportunities in the entire value chain. Last but not least, the aim is to bring about a change in awareness in the industry and in society as a whole in order to establish biobased processes. In addition, the project participants want to open up new fields of application in the areas of technical textiles, household textiles, clothing and in the automotive sector.

In 2019, the project management office was launched. It steers the strategic direction and manages the BIOTEXFUTURE project portfolio. In addition to the further development of the innovation space and the controlling function, a primary goal is the intensive exchange between the stakeholders of the individual projects to enable a good flow of information and synergies. Project management is led by Adidas on the industry side; RWTH Aachen University on the research side.

Transition Lab: Focus on consumers

The so-called "Transition Lab" project is intended to link those involved in the innovation space with their research ideas on the one hand and consumers and interest groups along the value chain on the other. The Transition Lab project team would like to use the insights gained from research to conduct surveys and gather opinions, while at the same time broadening knowledge and acceptance.

The feedback the team receives in the process is channelled back into the research projects. In this way, technological innovations and social changes are to be closely interlinked with the overarching goal of advancing the transformation to a biobased society. The project is led by RWTH Aachen University. Other participating institutions are the University of Bayreuth, the University of Heidelberg, the Friedrich-Albert-University Erlangen-Nuremberg, the University of Duisburg-Essen and the industrial partner Adidas.

Bio-based polymers, fibers and coatings

With regard to the actual research and development work, several projects have already been started. In the "BioCoat" project, the focus is on a process that makes it possible to provide biobased textiles with a protective layer that is also biobased. Specifically, the researchers want to develop a platform technology to combine protein-based adhesion promoters with functional proteins and peptides. This could result in water-repellent or antimicrobial finishes. The subproject will run from 2020 to 2023 under the leadership of the Leibniz Institute for Interactive Materials DWI. Other partners are the companies Frohn and Adidas.

Also in 2020, the "BioBase" project was launched. The aim is to replace one petroleum-based polymer product with one made from bio-based polymers in each of the automotive, sportswear, interior design and technical textiles sectors. These are to be equivalent in terms of handling and functionality. As a basis, the participants are looking at established biopolymers and would like to present product prototypes at the end. The project is led by RWTH Aachen University and AMIBM e.V.. Several textile companies are also involved.

Another sub-project from the first phase is "AlgaeTex". Its aim is to demonstrate polymer building blocks from microalgae for the production of synthetic fibers for sports textiles. The algae-based synthetic yarns are to be used in T-shirts or knitted shoe uppers. Since algae require only CO2 and sunlight, the production process would be more sustainable. The project will run from 2020 to 2023 and is led by Adidas and RWTH Aachen University. The University of Bayreuth and Fraunhofer IGB are also involved.

Bio-based coatings, artificial turf and geo-textiles

As a special feature of its funding activities, BIOTEXFUTURE launches its own calls for proposals for so-called seed fund projects and accelerator projects. The seed fund projects support innovative ideas for which proof of feasibility has yet to be provided. Six to twelve months may be budgeted for such a project and a maximum of 100,000 euros. Project ideas that already have proof of concept and want to accelerate the implementation of their idea, on the other hand, are funded via the Accelerator project. Here, projects with a term of up to two years are funded.

Two Seed Fund projects were launched in October 2021. The "PolyPFiber" project is developing an antimicrobial PLA multifilament yarn with polyphosphate. The "GOLD" project is looking at new ways to produce elastic textile fibers. To this end, the researchers led by Claudio Flores of Mimotype Technologies GmbH want to decipher the molecular and mechanical details of a particularly elastic collagen fabric, the gold beater skin in the bovine stomach. To obtain this biomaterial on an industrial scale, the team is developing a biotechnological process.

In addition, three other projects were launched at the beginning of 2022: "CO2Tex" uses carbon dioxide directly as a starting material for fiber production, "BioTurf" is developing a bio-based artificial turf surface for sports facilities, and in the "DegraTex" project, a research team is developing biodegradable geotextiles.

Page 3 of 5

Blue Bioeconomy in Northern Germany: The BaMS Innovation Space

Blue bioeconomy means using biological resources from oceans and other waters economically, fairly and sustainably. Specifically, the Innovation Space Bioeconomy in Marine Sites - BaMS is working on the development of aquatic circular economies and the integration of production processes for aquatic biomass into other material cycles.

The Innovation Space at a glance

Objective: Realize blue bioeconomy in Northern Germany, use aquatic resources sustainably and strengthen the blue circular economy

Partner: 45 institutions, including 28 companies and 17 universities and research institutes

Coordination: Christian-Albrechts University of Kiel (Dr. Stefan Meyer, Prof. Dr. Carsten Schulz)

Funding: up to 20 million euros

Duration: October 2019 to Dezember 2025

Website: blaue-biooekonomie.de

The basis of these circular economies are "blue" biomasses from algae, fish, mussels and other aquatic organisms, which not only serve as raw materials for processing in biorefineries. The project partners of the Blue Bioeconomy Northern Germany also use them to produce food and feed, cosmetics and petroleum-alternative feedstocks for agriculture, as well as sustainably generated nutrients for fertilizers. The aim is to utilize raw materials and residual materials as efficiently as possible and to close material cycles through new production and processing methods. This makes anAssociation as an anchor point of the Blue Bioeconomy important contribution to increasing the long-term usability of biogenic resources from the sea and other bodies of water.

Association as an anchor point of the Blue Bioeconomy

The Blue Bioeconomy Northern Germany is coordinated by the Christian-Albrechts University of Kiel (CAU) and unites 45 members (28 companies, 15 research institutions and two others) from Northern Germany. Organized as an association, the Innovation Space BaMS is based in Kiel. With support from the BMBF, up to 20 million euros in funding is available over a five-year period. Interested companies and research institutions can continue to join the Innovation Space and carry out projects and cooperative ventures with the other members. Beyond the end of the funding period, the association will remain as an anchor point of the Blue Bioeconomy in Northern Germany.

Developing marine aquaculture systems

The Innovation Space has already launched twelve projects, including "BioFiA". Here, a method will be developed to collect real-time data on the health and stress of fish in aquacultures, on the basis of which well-founded statements can be made about animal welfare and species-appropriate husbandry. In addition, participants are looking for factors that reduce stress in salmon at slaughter. Overall, the project aims to answer open questions about animal welfare and performance potential from the perspective of both the producing companies and consumers. Furthermore, the participants want to determine how the microbial community in aquacultures with closed material cycles is composed and what effects this has on the nutrient cycle in the facility. In addition to the leading research institute for farm animal biology, the Fraunhofer IMTE in Lübeck, the Max Rubner Institute for Nutrition and Food in Kiel and the universities of Hamburg, Kiel and Rostock are involved. Corporate partners are the specialists Monitorfish and Microganic.

The "SensoFiA" co-project is developing the tools, products and methods to directly monitor the health and stress response of fish in aquaculture. Massive progress in production performance and product quality should be possible via an improvement of fish welfare based on reliable stress detection methods in recirculating systems and net cages, the ratio says. The project is led by Fraunhofer IMTE and the Baader company.

Fully utilize algae biomass

The "BALI" project is developing a biorefinery concept for algae-based ingredients. Subprojects are evaluating how the biomass of macroalgae and microalgae can be used as completely as possible (cascaded) in several successive processes. Fatty acids, complex sugar molecules and bioactive metabolic products of the algae are obtained in this way. The focus is on two applications and products: a natural cosmetic skin lightener based on macroalgae and algae sugars for the cosmetic and pharmaceutical industries and for fine chemicals. The project is led by the University of Greifswald. Other participants are the Institute for Marine Biotechnology Greifswald, GEOMAR Kiel and the companies BlueBioTech, oceanBASIS, Coastal Research & Management and Enzymicals.

The project "LaMuOpt" aims at the holistic use of brown algae and mussel by-products to optimize cycle-based fish farming and products for human consumption. Whether for food or as raw materials for cosmetics and pharmaceuticals, mussels and algae are usually not fully utilized. The project participants want to use the resulting residual materials, such as mussels that are too small and macroalgae pomace, to produce fish feed for aquaculture systems with closed material cycles and innovative foods. The project is led by Fraunhofer IMTE, with the University of Kiel and Coastal Research & Management also involved.

The "ÖkoPro" project is about integrating the production of microalgae and aquatic biomass into agricultural processes. Synergies are created through the use of nutrient-rich surface water from biogas plants and the utilization of surplus nutrients, CO2 and heat. Additional income is generated by marketing algae biomass as animal feed and cosmetic raw material. The project will test different production systems, evaluate process parameters and identify particularly suitable aquatic biomasses. The 3N Competence Center for Renewable Resources and Bioeconomy Lower Saxony is leading the project, and the companies Microganic, oceanBASIS, BES and GICON as well as the Christian-Albrechts University of Kiel and the University Hospital Schleswig-Holstein are also involved.

The integrated husbandry of groupers and salt plants in marine aquaculture systems with closed material cycles is the focus of the "OptiRAS" project. Residual materials are to be converted into fertilizer and biochar. The project is led by the Alfred Wegener Institute in Bremerhaven; the company Aqua-Sander is the corporate partner.

The "HaFF" project clarifies nutrient-polluted wastewater and surface water from fish farms with the help of saline plant cultures (bioremediation). This means that the nutrients in the wastewater from aquaculture facilities or in nutrient-polluted surface waters are reduced by using flood- and salt-tolerant plants in floating modules or on constructed plant beds, so-called constructed wetlands, to build up their biomass. The project is led by Coastal Research & Management, and also involves EUCC, Fraunhofer IMTE, Hanffaser Uckermark, Kieler Meeresfarm, N.A.T. and re-natur Havelland.

Accelerator for start-up projects and SMEs

The "AQUATOR" sees itself as an accelerator for the development of the aquatic bioeconomy. AQUATOR's goal is to sustainably develop the economic and ecological potential of the marine bioeconomy. To this end, consulting - technical, ecological, financial, social, administrative -, services and infrastructure are being established along the value chains. The project is particularly aimed at founders and existing small and medium-sized enterprises in the aquatic bioeconomy. The project is led by Coastal Research & Management, also involved are the TH Lübeck, the University Hospital Schleswig-Holstein, the Christian-Albrechts University of Kiel, the Carl-von-Ossietzky University Oldenburg and the Fraunhofer IMTE.

In January 2022, two further co-projects were launched: "OnAsta" will develop ultra-fine sensor technology for optimized production of the high-priced microalgae dye astaxanthin; the lead company is Sea& Sun Organics. "VACO2" will improve ammonium and CO2 emissions in biogas reactors through innovative processes such as microalgae utilization. The project leader is the company B.E.S.

Model site on Rügen

In Bergen on Rügen, there is also a new model site since January 2022. There, researchers from the University of Rostock, the Research Institute for Farm Animal Biology (FBN) and the company Michelli Gruber Landwirtschaft (MGL) are jointly developing the "Bioeconomic Research Center Rügen" under the project title "RüBio". Also involved are the company LimnoSystem and the University of Kiel and the University of Greifswald. On the former industrial site, different cycles are combined in a meaningful way (for example insect breeding, hydroponics, aquaculture) and economically exploited. Inter-European projects, research and transfer are to be united under one roof. In addition, visitors will soon be able to tour the facility, experience bioeconomy as a guided tour, and purchase the locally produced medicinal herbs, food, and products on site.

More on bioökonomie.de

Interview: Carsten Schulz - Fraunhofer IMTE

Page 4 of 5

Urban Bioeconomy: The BioBall Innovation Space

Agriculture, forestry and fisheries traditionally provide the raw materials for the bioeconomy. However, all three sectors are usually more associated with rural areas. In metropolitan areas, on the other hand, residual and waste materials are the major resource. Using these simultaneously reduces the amount of waste and environmental pollution. The innovation space "BioBall - Bioeconomy in the Metropolitan Area" aims to leverage the potential of the bioeconomy in and for the FrankfurtRhineMain metropolitan region.

Der Innovationsraum im Überblick

Objective: Material use of biogenic residual and waste streams in the FrankfurtRhineMain metropolitan region

Partner: 31, including 16 companies and 15 universities and research institutions

Coordination: Provadis School of International Management and Technology AG (Prof. Thomas Bayer) supported by the professional society DECHEMA

BMBF funding: up to 20 million euros

Duration: 2019 to 2025

Website: biooekonomie-metropolregion.de

The aim of the BioBall Innovation Space is to promote the material use of biogenic residual and waste materials and to advance the structural change toward a biobased economy. To this end, bio-based by-product and residual material streams from the private and municipal sectors are being developed for the food, chemical and pharmaceutical industries. In addition, the people of the region will be involved in the projects in order to create acceptance for the technology and to identify and discuss possible conflicting goals.

The FrankfurtRhineMain metropolitan region is home to 5.8 million people. Every year, 900,000 metric tons of biowaste - including 200,000 metric tons of food waste -, 146,000 metric tons of sewage sludge, 125,000 metric tons of biogas from fermentation, and 90,000 metric tons of lignin from paper production are generated. In addition, there are further biogenic residues from industry.

Insects as fish food

Eight projects have already been launched. " From 2020 to 2022, "INFeed" is pursuing the goal of feeding insect larvae with food scraps in order to use them as animal feed. Due to their nutrient composition, the insect-based feeds have a positive impact on animal health and should thus help reduce the use of antibiotics. A modular platform technology is to be developed to produce suitable insect-based feeds for different livestock - from marine animals to poultry.

The project will initially focus on shrimp farming in aquaculture. The aim is to produce high-quality and sustainable food close to the city. In addition, the facilities will be run with closed water circuits in order to largely avoid waste and to optimize the overall eco-balance of the food produced. The project is being led by TH Mittelhessen, and other participants include the Fraunhofer Institutes IME and IWKS, the University of Giessen, and the companies Evonik, August Storck, Doehler, and Herbstreith & Fox.

Utilizing residual material streams from the wood industry

In the "GlyChem" project, researchers will develop extraction and refinement processes from 2020 to 2023 to produce valuable substances from lignocellulosic waste streams from the wood industry and agriculture. Glycans in particular are to be produced in this way. Currently, both extraction and purification, but also the chemical modifications for further use are usually not yet economical. The simultaneous production of products coupled to the process, such as polyphenols and carboxylic acids, are one approach to changing this. The extraction and modification processes required for this are being developed in the project. Fraunhofer IWKS is in charge of the project. Also involved are the TU Darmstadt, the TU Clausthal, the University of Würzburg, the Fraunhofer Institute for Silicate Research, as well as Herbstreith & Fox and Südzucker from industry.

"GreenToGreen" is the motto under which municipal green waste is to be used as the basis for green chemistry. From 2020 to 2023, the project participants want to research how green waste can be used in fermentations and explore whether it can be used to produce electrode material for electrobiotechnology. The result will be microbial or enzymatic fuel cells. Compared to the use in biogas plants or composting, this would be a significantly higher added value. The advantage of this approach is that green waste has not yet been used. The project is being coordinated by the TH Mittelhessen, with the cooperation of the TU Kaiserslautern and the ifn FTZ also being supported. A corresponding logistics concept for the collection of the green waste is being developed by the city of Frankfurt am Main and its municipal operations.

Tapping carbon from exhaust gases

Not only the raw material, but also the process is biobased in "SynBioTech" - because it is about the synergistic development of biotechnological and chemical processes for the value creation of decentralized C1 material streams. What is meant by this is that the carbon dioxide content in biogas is chemically converted to methanol. The methanol serves as feed for the bacterium Methylobacterium. The microorganism can process it into proteins for the animal feed industry or acid derivatives for the chemical market. The project is led by Darmstadt Technical University. Other participants include the University of Marburg, Provadis University of Applied Sciences, the Max Planck Institute for Terrestrial Microbiology, DECHEMA Research Institute and, on the industry side, Infraserv Höchst and Wacker Chemie.

The "AbZuMeOH" project is also concerned with methanol. Here, too, the approach is to utilize the carbon dioxide produced during the combustion of biogenic waste or the production of burnt lime as a material. The hydrogen required for methanol synthesis in addition to the CO2 is to be obtained electrolytically from water, the energy required for this from the thermal treatment of the biogenic waste, supplemented by electricity from renewable energies. The methanol produced is to be pure enough to be used for fuels or plastics. The project is coordinated by bse methanol Leipzig, with Schaefer Kalk, Infraserv Höchst and Provadis University also involved.

From 2021 to 2024, the "CtC" project will investigate how glycols can be produced from waste streams containing carbohydrates. The aim of the project is to develop an economically and ecologically viable purification and conversion process for sugars obtained from plant biomass from the food production chain. Since the current process still produces a large number of by-products, another goal is process optimization with a reduction in by-products in order to improve the life cycle assessment as well as the added value. The project is a cooperation between Air Liquide as coordinator and Provadis University as partner.

Waste cooking oils into insulating materials

Two further projects "AMP Food" and "BIOTESS" have been launched in 2021. AMP Food builds on the findings of INFeed and produces customized antimicrobial peptides from insects. The project is coordinated by the Fraunhofer Institute IME and implemented in cooperation with Van Hees.

BIOTESS is pursuing the production of biobased phase change materials (PCMs) from liquid waste substrates from biowaste treatments, used cooking fats, and from grease residues from grease traps, such as those produced in canteens or the food service industry. The PCMs are needed in particular for insulating materials in the construction industry. This project is coordinated by the TU Darmstadt, partners in the project are AWB, EAD Darmstadt, Jager Biotech, Rösner Ingenieurbeton and e-hoch-3 for a market analysis of the technology.

Accompanying research and science communication

Within the framework of the scientific accompanying project TransRegBio, all mentioned research projects are continuously evaluated with regard to their economic and ecological potential. This ensures that the needs of users and the market can be developed with environmental impacts in mind. In the long term, the technologies and processes are to be scaled up and also support other metropolitan regions on their way to a circular biobased economy.

Since a bio-based, sustainable economy only has a chance of becoming reality if there is also broad acceptance among the population, the Innovation Space facilitates networking among interested stakeholders in regular virtual and face-to-face formats. In the „BioBall-Podcast“ (in German), stakeholders of the Innovation Space have their say and discuss new technologies, future markets and the necessary regulatory framework.

Page 5 of 5

The Innovation Space NewFoodSystems

The Innovation Space "NewFoodSystems" brings together stakeholders from food and nutrition research and the food industry along the entire value chain in order to transfer innovations into practice even more efficiently.

The Innovation Space at a glance

Objective: Partners from industry and science explore and develop new food systems as well as production systems for food and feed products

Partner: 59 partners, including 40 companies, 18 universities and research institutions, and one association

Coordination: Max Rubner Institute (Prof. Dr. Sabine E. Kulling), supported by the Fraunhofer Institute for Process Engineering and Packaging (IVV)

Funding: up to 20 million euros

Duration: December 2019 to December 2025

Website: newfoodsystems.de

The aim is to test new production methods and cultivation processes for food and to develop marketable solutions. The claim is the holistic evaluation approach for these products and processes, which includes the legal framework, quality and safety, consumer acceptance, economic viability, marketability and sustainability.

Innovative production systems for food and feed

The German Federal Ministry of Education and Research will provide up to 20 million euros over a period of five years. The activities of the Innovation Space, which was launched in December 2019 and now includes 59 partners from research and industry, cover three fields of innovation:

- Production under controlled conditions (Controlled Environment Cultivation)

- Production and application of new food and feed ingredients

- Resource-efficient energy and material flow management with system integration

At the end of the term, the aim is to develop new food products of high quality and safety that are accepted by consumers and have all the prerequisites to be successful on the market. The Innovation Space is coordinated by the Max Rubner Institute (MRI), supported by the Fraunhofer Institute for Process Engineering and Packaging (IVV).

Database for alternative proteins

One of eight projects currently underway is entitled "Alternative Protein Ingredients." Although there are alternatives from plants, algae or insects to today's mostly dominant animal protein sources, which proteins have which properties and what they are particularly suitable for in foods has hardly been systematically recorded so far. The core of the project is therefore the creation of a protein database. This will systematically record information (obtained experimentally or researched) and contain important parameters ranging from technofunctionality and biological value to sustainability. In this way, food manufacturers will be able to identify the most suitable combination of proteins for their products. The project also aims to demonstrate the latter in practice. The project is being led by the University of Bonn. On the research side, a team from the Fraunhofer IVV is also involved. In addition, eleven food companies are project partners.

The project goal of "Protein Layers," another project led by Kalle GmbH, is edible packaging for the food industry. The packaging developed in the project is to be based on plant, algae or fungal proteins and at the same time fulfill all the important properties of food packaging. A first product will be a collagen-based casing for vegan sausage alternatives.

Experience food of the future in the museum

Another project deals with the social acceptance of nutrition innovations and their communication. The location and project leader for this is the "Future Museum" of the Deutsches Museum in Nuremberg, which opened its doors to visitors in September 2021. An interactive station in the museum presents both realistic and futuristic meals. Trends and results from the Innovation Space's research activities will also be presented there to inform visitors and learn about their dietary choices. These reactions and the level of acceptance will eventually feed back into the project.

Further develop indoor farming systems

Climate change and dwindling fertile arable land, in addition to densely populated urban areas and regions with little productive land for traditional agriculture, make indoor farming and vertical farming an attractive option in the future. The "In4Food" project, led by the Max Rubner Institute (MRI), is dedicated to this new form of cultivation. On the one hand, it is about the weed-free production of herbs, on the other hand, it is about the cultivation of non-native raw material plants that are used for the extraction of natural aroma components. The project partners want to optimize process parameters to produce safe and high-quality products, but also identify microorganisms that have positive effects on plant growth and health, especially under indoor farming conditions. Last but not least, the entire project is to be tested in a new plant concept under practical conditions. In addition to the MRI, project participants include the Fraunhofer IME, the Julius Kühn Institute and the companies Symrise, Nadicom and Van Hees.

Another indoor farming project, "SustainVanil", led by the HS Osnabrück, focuses on the more sustainable cultivation of vanilla. The researchers are taking a two-pronged approach: First, the project is developing an indoor cultivation system that will enable vanilla cultivation in Germany. This requires a better understanding of the physiological processes of the vanilla plant. These should additionally serve to establish biological plant protection measures. Secondly, the findings are to be used to improve the cultivation of vanilla established in Madagascar and to stabilize yields.

Insects for food and animal feed

As part of the "reKultI4Food" project, researchers want to develop insect protein for feed and food by using food production residues and by-products as nutrients for the larvae of the black soldier fly. So far, however, the economic production of insect protein has proved difficult, as the production and processing methods for insect protein cannot yet compete with conventional protein feeds such as fish meal or soy. In addition, the value-added potential of insect ingredients has hardly been exploited to date. Both challenges will be addressed in the project, which is led by FiBL Germany.

Process algae biomass in a controlled manner

"ALGAE-MODULE 4.0", coordinated by TU Berlin, aims to provide a best-practice example of how production and processing of fresh algae biomass with constant and adjustable properties for various applications is possible. Sensors are to continuously monitor and optimize algae growth. Advanced technologies will then enable processing into two fractions, separating high-value ingredients from proteins for the production of meat alternatives, for example.

Holistic evaluation

Innovations in the food sector can only be successful if important factors are met. This is the starting point for the "Holistic Evaluation" project, which aims to develop a methodology at the conceptual level that includes assessments of sustainability, economic viability, consumer acceptance, quality, safety and jurisdiction and relates and combines the respective results. The multiple steps of analysis will be carried out on a concrete example -insect-based food and feed. Emphasis is also placed on the sustainability assessment of alternative proteins.

Markets and utilization opportunities in view

The Innovation Space also offers the partners a platform for discussion and exploration of new ideas and technologies. All projects are accompanied by an Innovation Hub, organized by the Fraunhofer IVV with the support of fors.earth GmbH and the MRI, whose goal is to explore markets and exploitation opportunities at an early stage and thus quickly transfer the results of the Innovation Space into practice. In the course of the Open Labs offer, start-ups are given the opportunity to use technical pilot facilities at partner institutions. Dialogue with society and other stakeholders is specifically sought in order to counter potential barriers to acceptance of new foods and production methods at an early stage. The innovation hub also serves as the core for the continuation of the innovation space.