PLA plastics suitable for air filters

Nonwovens made from the bioplastic polylactide can remove virus-laden aerosols from rooms equally well as conventional plastic filters.

From offices to classrooms: Air filters have been booming since the outbreak of the pandemic. They can be used to remove virus-laden aerosols from rooms and thus reduce the risk of infection. Ideally, filter materials should also be environmentally friendly. For this reason, researchers from the Zuse community have taken a close look at nonwovens made of bioplastics as filter materials and examined them for filter performance and durability.

Suitability of PLA nonwovens tested for biofilters

The "BioFilter" project focused on the suitability of polylactide - PLA for short. The biocomposite, also known as polylactic acid, is already used in a variety of ways, especially in the packaging industry. The disadvantage: PLA becomes brittle easily, has a low temperature resistance of 60 degrees Celsius and is therefore not very suitable for hot drinks, for example. Researchers from the German Textile Research Center North-West (DTNW) and the Saxon Textile Research Institute (STFI) have now tested the properties of various PLA granules in the project with regard to their suitability for nonwovens for biofilters.

Good filter performance and stability at low temperatures

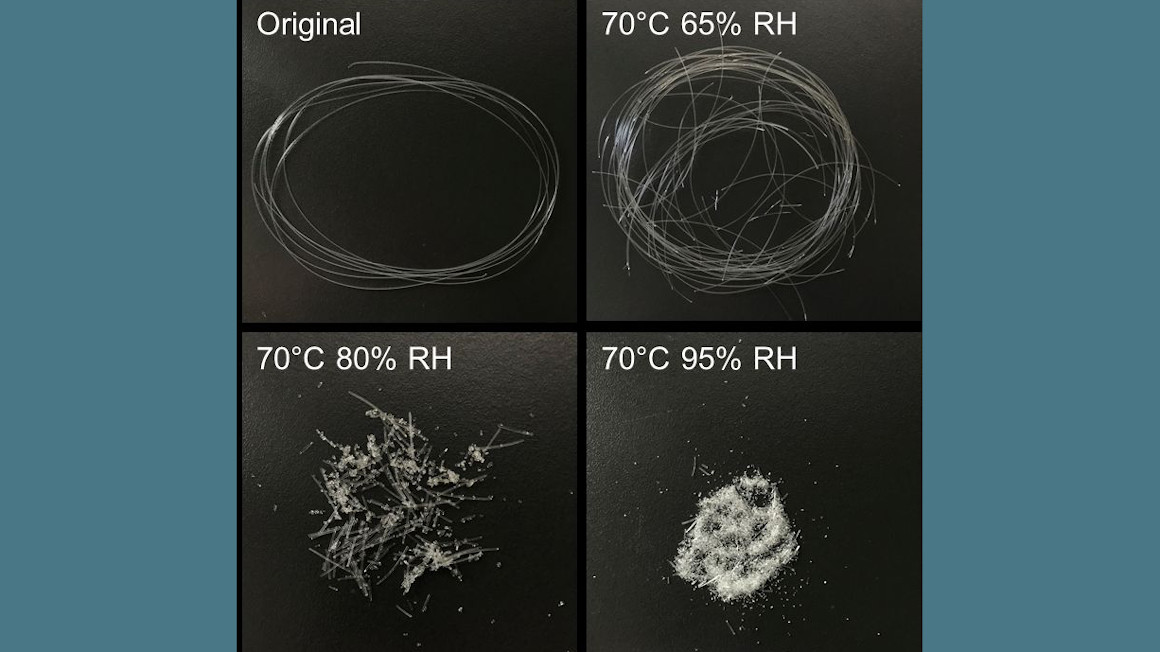

It was not the nonwovens themselves that were tested, however, but so-called monofilaments. The PLA fibers were tested for aging and durability in a climate chamber. The results showed that at temperatures above 70 degrees Celsius, the monofilaments became brittle after two weeks. Under normal conditions, however, the PLA filaments were still stable after a simulated three years. The filtering performance of the PLA nonwovens was also able to keep up with air filters made of conventional plastics. "In my opinion, the focus for the use of PLA as a filter material will be on applications with low temperatures, with which PLA copes very well," summarizes DTNW scientist Christina Schippers.

Also suitable for water-oil filtration

In addition to its suitability for air filters, the PLA biocomposite was also tested for other influencing factors such as mechanical stresses caused by air currents. Based on the results, the project partners will be able to clearly define the areas of application for PLA nonwoven filters in the future. Furthermore, it has been established that such bio-filters could not only filter corona viruses from the air, but could also be used in industrial kitchens for water-oil filtration or in industry for engine oils.

The project "BioFilter" was realized within the framework of the Bioeconomy Cluster of the Zuse-Gemeinschaft and supported by the Federal Ministry of Economics. "For us, the bioeconomy is a top cross-industry topic that connects numerous institutes of the Zuse-Gemeinschaft and is brought to life through collaborations such as the 'Bio-Filter'," explains the future STFI Managing Director Heike Illing-Günther.

bb