Microbes isolate precious metals in pilot plant

The German industrial biotech company Brain AG has developed a new bio-leaching method to isolate and retain metals by breaking down waste and ore.

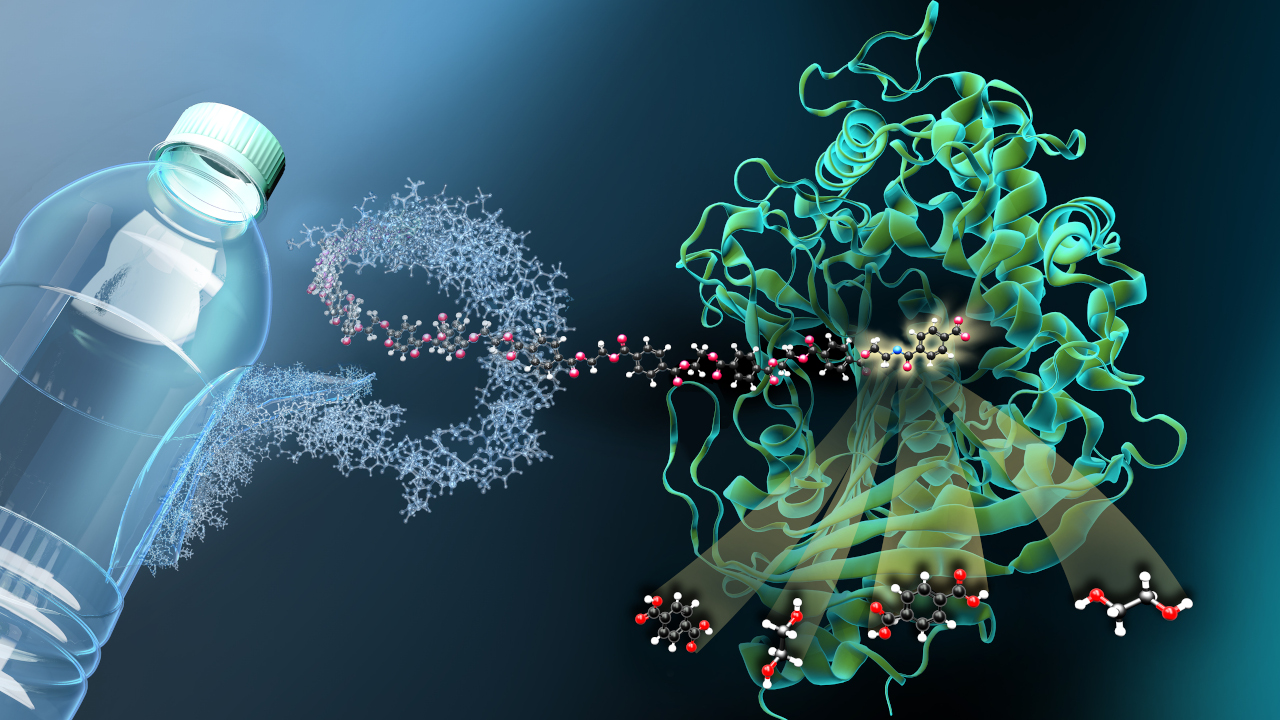

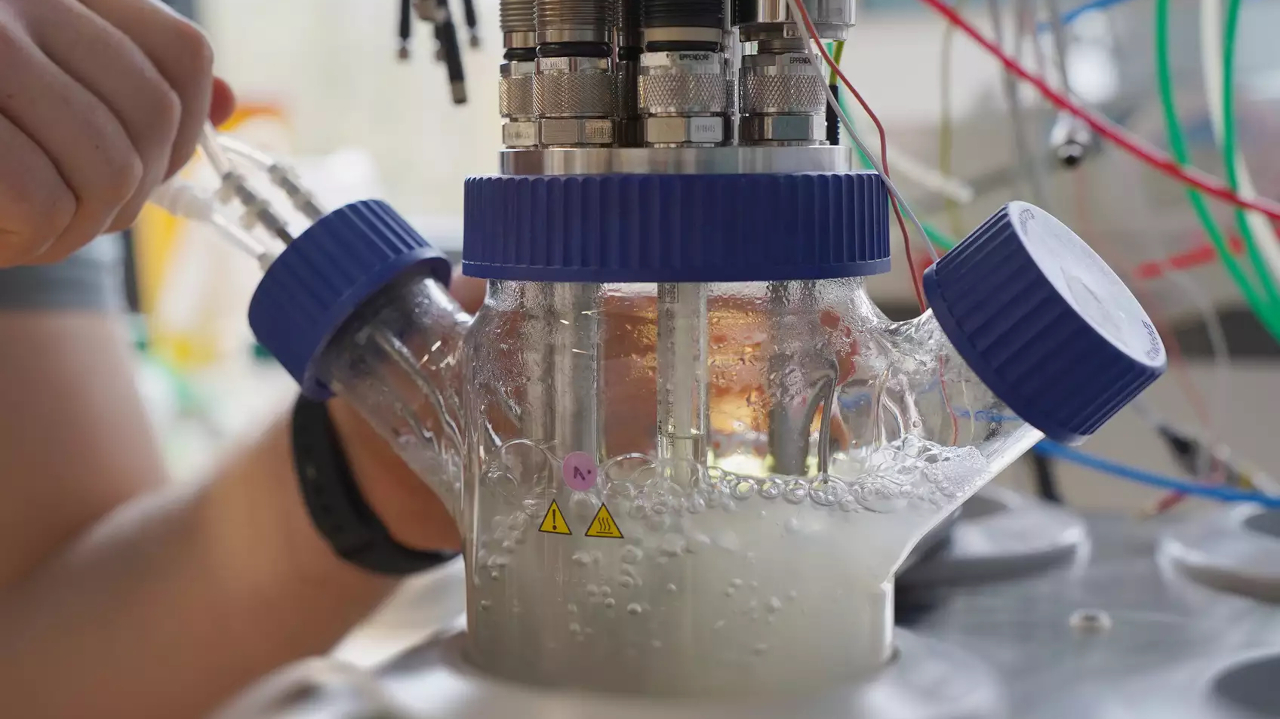

An international research team involving scientists from Brain AG has succeeded in extracting nearly the entire copper content from local shale deposits by applying a novel bio-leaching process. In the early extraction phase, microbes that are used for the bio-leaching process first convert insoluble ore minerals into water-soluble salts. Downstream, a bio-chemical precipitation process then recovers up to 97% of the dissolved copper. A recently finalised demonstration unit, the Brain BioXtractor, offers biological process solutions to extract and recover precious metals from side and waste streams as well as from primary resources. The unit is a self-contained system equipped with fermenters close to industry scale. The system is built to be easily disassembled and adjusted to customer requirements on-site. Currently, the BioXtractor can be explored by enterprises interested in a test phase prior to joint further development and commercialization or licensing the technology.

Growing significance of Green Mining

For the new bio-leaching process Brain helped identify carbonate-dissolving, metal-resistant micro-organisms from their proprietary BioArchive, which contains more than 53,000 micro-organisms. In addition, Brain also provided their expertise regarding physiological and genetic micro-organism characterization. “This successful research project underscores the increasing significance of Green Mining and Urban Mining, both of which are areas in which we conduct intense research. We focus on the low-impact and efficient extraction and recovery of precious metals, such as gold, silver and other technology metals, from ores and waste streams. Source materials include electronic scrap, incineration bottom ashes and metallurgical slags,” says Guido Meurer, Member of the Management Board and Unit Head Producer Strain Development at Brain.

Where raw materials are scarce, new extraction methods are needed

Especially for regions such as Germany, where raw materials are scarce, new processes that allow for the sustainable extraction and recovery of metals are an increasingly important field of research and development. Esther Gabor, Program Manager Green & Urban Mining at Brain, says: “There is an increasing demand in precious metals, which play a key role in many high-tech applications. Based on biotechnological processes, Brain has developed various bio-based solutions for Green and Urban Mining as they are essential for an efficient circular economy.”

A Franco-German cooperation

The research project was co-managed by the French Geology and Mining Research Bureau (Bureau de recherches géologiques et minières, BRGM) and the German Helmholtz-Zentrum Dresden-Rossendorf (HZDR). The goal was to develop an energy and raw material efficient recovery process with a small ecological footprint that utilises local primary resources.

The copper recovery through bio-leaching research project was part of the EcoMetals scheme co-funded by the German Federal Ministry of Education and Research (Bundesministerium für Bildung und Forschung) and the French National Research Agency (Agence Nationale de la Recherche, ANR). The research results were presented on the occasion of the 22nd International Biohydrometallurgy Symposium held at Freiberg Technical University for Mining (TU Bergakademie Freiberg) in late September 2017.

jmr