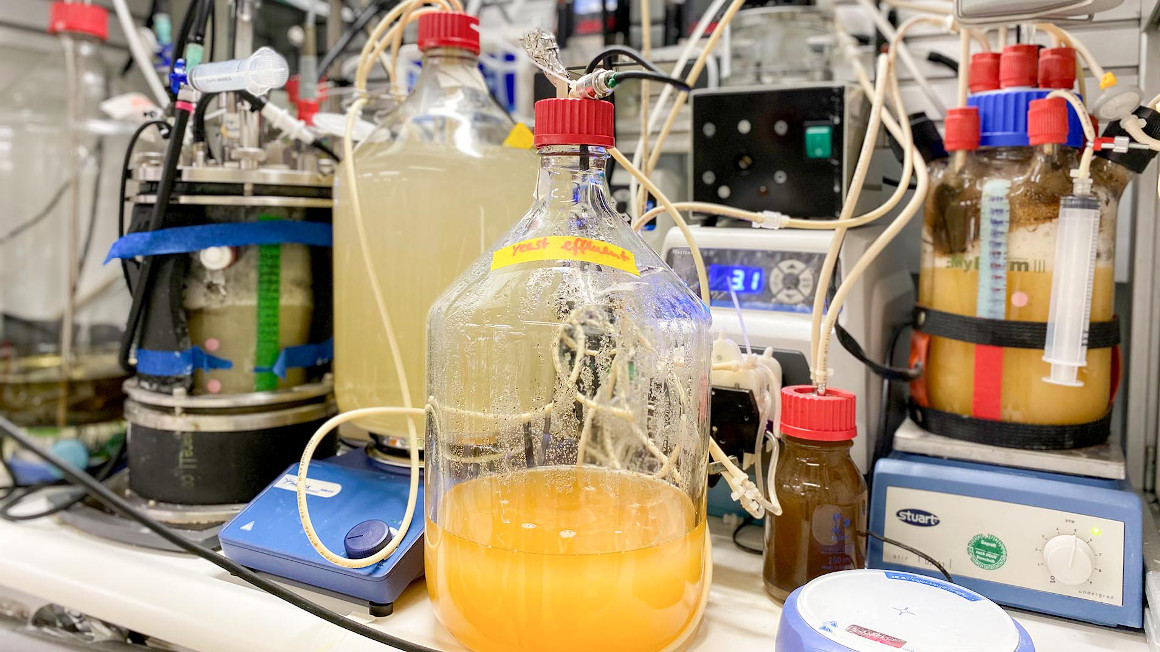

Folic acid from the bioreactor

Researchers at the University of Tübingen have used CO₂ and green electricity to produce valuable proteins and vitamins that can be used to make meat substitutes.

Microorganisms can produce a variety of substances. Their talents have been utilised for centuries - for example in the production of beer, wine and cheese. Microbes are also important tools for biotechnology, for example to produce new products such as bio-based chemicals for the bioeconomy from CO2. Researchers at the University of Tübingen have now developed a bioreactor system in which valuable nutrients for the food industry are produced from carbon dioxide, hydrogen and oxygen in two steps using a bacterium and baker's yeast powered by green electricity.

Power-to-protein system further developed

This involves both proteins and the vital vitamin B9 - also known as folic acid. As the team reports in the scientific journal ‘Trends in Biotechnology’, the existing power-to-protein system had to be further developed for this purpose. In the first system, two different microbes were used one after the other, explains Lars Angenent from the Environmental Biotechnology Department at the University of Tübingen. ‘A Clostridium bacterium reduced carbon dioxide with hydrogen in the absence of air to form acetate, which the baker's yeast, a fungus, then converted into proteins in the presence of air. Humans cannot live on protein alone,’ says the researcher, ’so we wanted to co-produce vitamin B9.’

For the first system to work, the microbes had to be fed with certain vitamins such as B9. This had to be avoided. It was important to the researchers that no more vitamins were fed into the process than could be extracted.

Heat-loving bacterium produces folic acid itself

The researchers were helped here by the heat-loving bacterium Thermoanaerobacter kivui, which replaced the Clostridium bacterium in the first stage of the power-to-protein system. Thermoanaerobacter kivui is much more frugal and can even produce the folic acid required for acetate production itself, the researchers write. In the second step, the baker's yeast then produced large quantities of folic acid.

Baker's yeast uses acetate instead of sugar to produce folic acid

It is known that baker's yeast produces folic acid from sugar. The experiments conducted by the Tübingen researchers have now shown that baker's yeast also produces the vitamin using the same amount of acetate as a starting material. ‘As we no longer add vitamin B9, we are certain that it is produced in the process,’ emphasises Angenent. According to Angenent, around six grams of the produced and dried yeast would be sufficient as a daily dose of vitamin B9 for a person.

According to the researchers, the microbially produced folic acid is not yet a finished food. Substances that can trigger gout must first be removed from the yeast. The bioreactor system also only exists on a laboratory scale for the time being and needs to be scaled up so that larger quantities can be produced.

Grundlage für Fleischersatzprodukte

However, the Tübingen research team is convinced that its new system has created the basis for the production of vegan and vegetarian meat substitutes and will therefore also contribute to food security in the long term. ‘The growing world population is threatened by malnutrition, especially in countries that suffer from drought and whose soils contain too few nutrients. Substitute products such as the ones we produce could improve the nutritional situation,’ says the researcher.

bb