Cellulose-based materials as PFAS substitutes

As part of an EU project, Fraunhofer ISC is working on a bio-based alternative to so-called 'Forever Chemicals' for packaging and textiles.

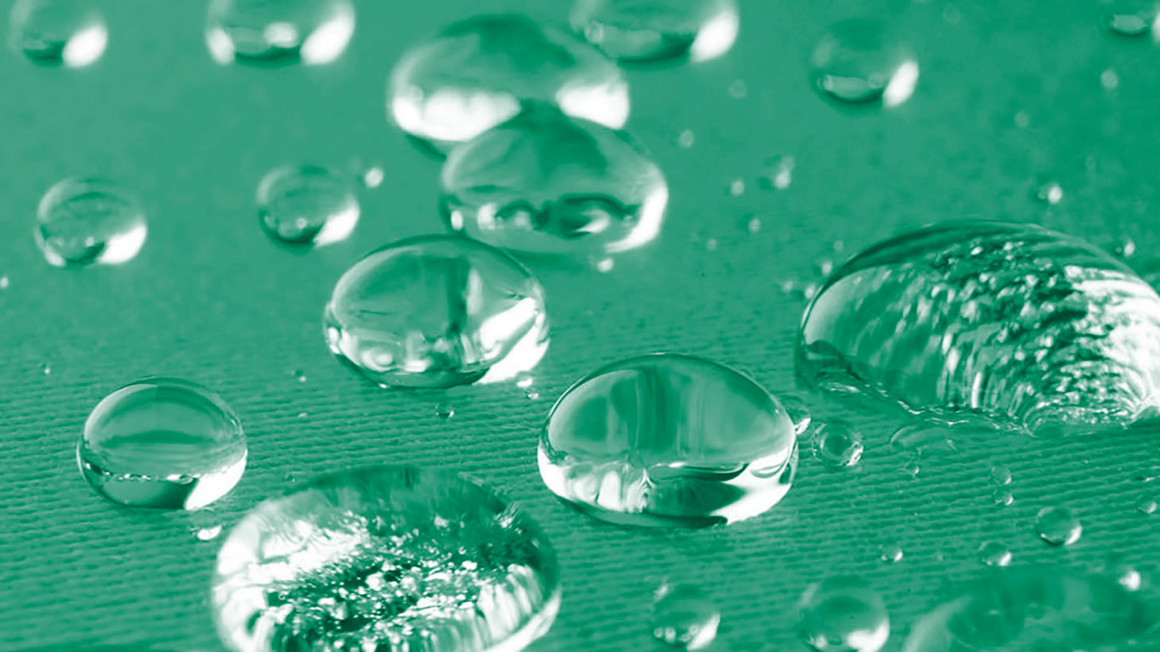

Whether in food packaging, cosmetics, pesticides or outdoor textiles: per- and polyfluorinated alkyl substances – PFAS for short – are contained in many products. These industrially produced chemicals are not only particularly resistant to oil and water, but also to temperatures and chemicals. As diverse as the applications of PFASs are, these substances are equally dangerous when they enter the environment, where they cannot be degraded naturally. PFASs have been detected in more than 70% of groundwater monitoring wells in the EU. Studies have also attributed illnesses and deaths to PFASs.

Research on PFAS-free solutions

The EU Commission therefore wants to ban particularly critical representatives of the so-called Forever Chemicals. At the same time, it is promoting research into environmentally friendly alternatives to replace PFAS. In the EU project ZeroF, researchers from the Fraunhofer Institute for Silicate Research ISC are currently working with industrial companies and research institutes from eight countries to develop PFAS-free solutions for food packaging and textiles. The Fraunhofer team is contributing its expertise in the development of omniphobic (oil- and water-repellent) and abrasion-resistant coatings for textiles.

ORMOCER lacquer as PFAS substitute

Specifically, the hybrid and versatile base material ORMOCER developed by Fraunhofer ISC is to be used here in the form of a coating and combined with cellulose-based materials from the project partner VTT. "The main challenge for us is to produce a water-repellent coating for textiles that can be applied as a water-based solution at the same time, as this is a requirement of the textile industry," explains Claudia Stauch, project manager at Fraunhofer ISC. "The ORMOCER as a hybrid material allows us to combine inorganic and organic material characteristics and thus generates endless possibilities for solving this complex issue."

This technology can therefore also be used to increase the biobased content of materials and thus make products more sustainable. In numerous applications, the researchers have already been able to prove that products with ORMOCER coatings are not only easy to process, but also have good surface and barrier characteristics and are easier to recycle.

Support for the implementation of PFAS-free alternatives

According to the researchers, whether the materials developed in the EU ZeroF project will become established in industry depends decisively on their acceptance. The Fraunhofer team is therefore already supporting companies in the implementation of environmentally friendly and economical PFAS alternatives. "The full range of functions of PFAS is not always really needed. For some of the current fields of application, where only one or two key characteristics from the entire PFAS spectrum are needed, there are already good solutions that can be used in the short term," explains Strauch.

bb