Biodegradable implant coatings

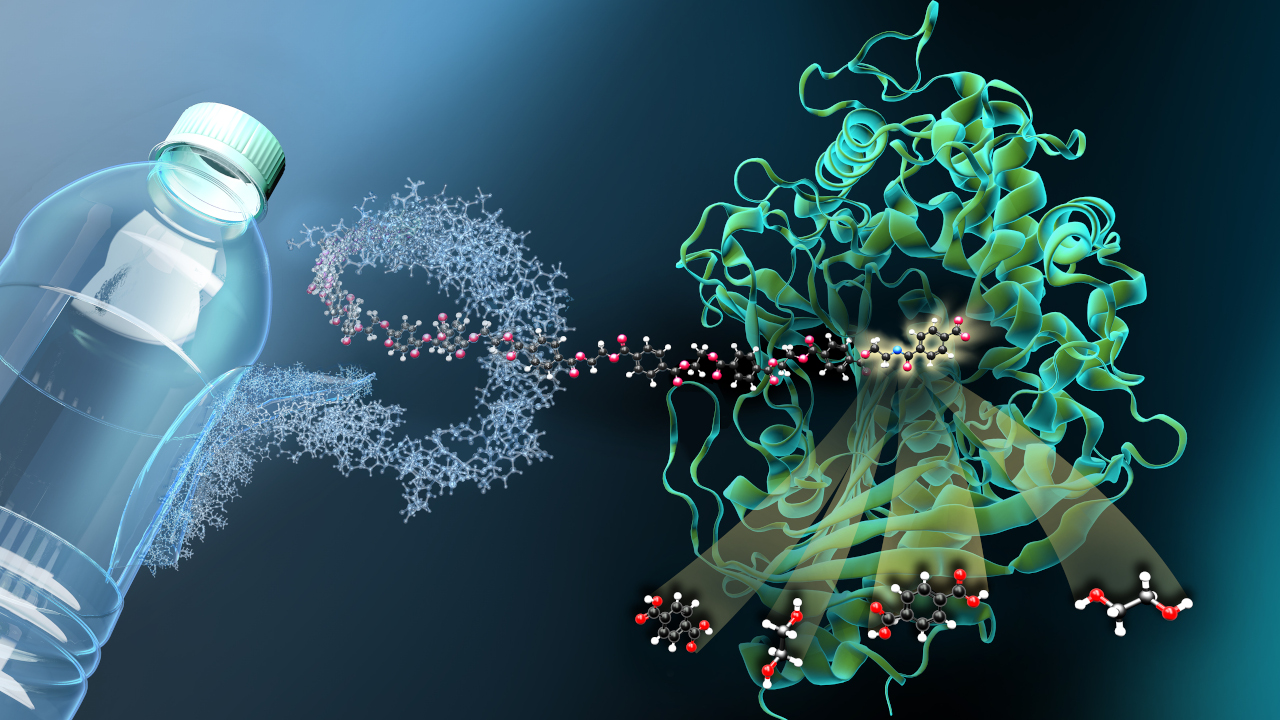

In a first, chemists in Karlsruhe have developed a biodegradable surface coating for implants.

Surgical suture material or drug-releasing stents are coated with substrates that release active agents or allow for better adhesion of biomolecules and cells. The film is applied using a special technique known as Chemical Vapour Deposition (CVD), involving gas-phase coatings. In CVD polymerisation, the initial compounds are evaporated, activated at high temperature and deposited onto surfaces where they polymerise. The problem thereby: to date, there has been no degradable gas-phase coating suitable for those medical implants intended to remain in the body for a brief period only before they degrade from within. Researchers from the Karlsruhe Institute of Technology (KIT) have now found a solution to the problem.

Degradable polymer film for the medical industry and food packaging

In the scientific journal "Angewandte Chemie", the researchers, who worked in collaboration with scientists in the USA and China, have presented a first: a CVD technique that results in a degradable polymer film. Via special side groups, biomolecules or active agents can also adhere using this method."Our new degradable polymer films could be widely applied for the functionalisation and coating of surfaces in areas ranging from the biosciences to the medical industry to food packaging," explains Joerg Lahann, Co-Director of the Institute of Functional Surfaces at KIT.

Monomer duo achieves water solubility

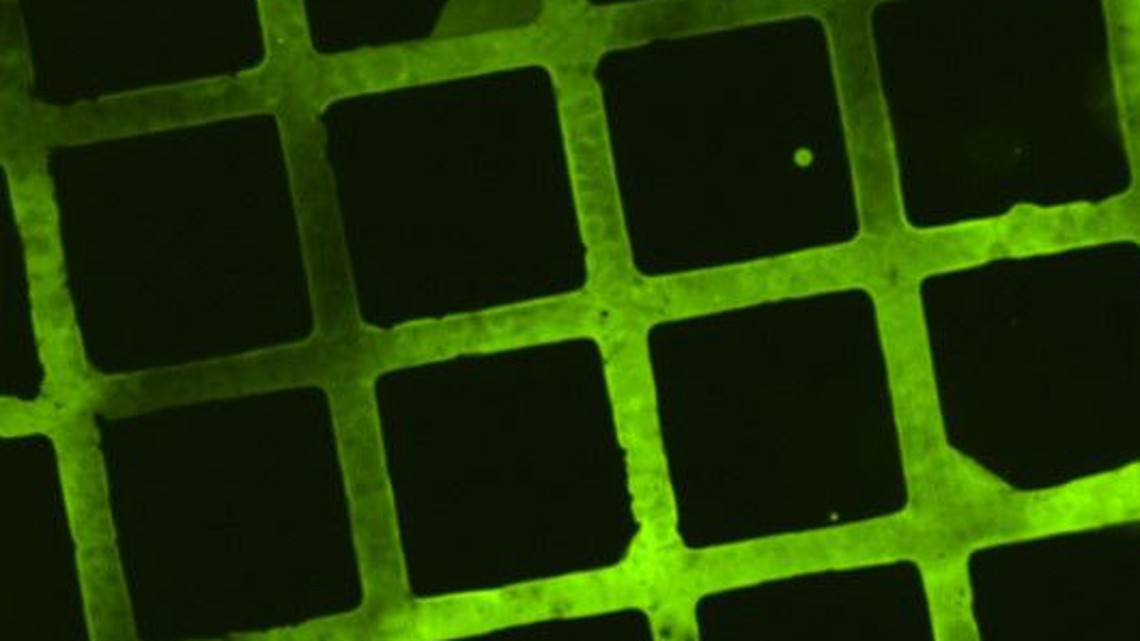

The biodegradable polymer coating was made possible owing to the co-polymerisation of two special types of monomer: the para-cyclophanes usually employed for this method were combined with cyclic ketene acetals. While classical polymers formed by para-cyclophanes are linked exclusively by carbon-carbon bonds, ketene acetal is rearranged during polymerisation so that ester bonds form in the polymer backbone. Those can be broken down in liquid media.

Degradation proven non-hazardous

According to Lahann, the rate at which the polymer coating degrades depends on the ratio of the monomer types and the monomer side groups."Polar side groups make the polymer film less water-repellent and accelerate degradation, since water can enter more easily. That allows for the rate of degradation to be adapted to suit the application in question", clarifies the researcher. Using cell cultures, the researchers have already demonstrated that degradation products are non-hazardous to health, i.e. non-toxic.

bb